Jim Michalak's Boat Designs

1024 Merrill St, Lebanon, IL 62254

A page of boat designs and essays.

(1 August 2018) This issue start propellers. The 15 August issue will continue the topic.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the.... ON LINE CATALOG OF MY PLANS......which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

| Left:

Tom Burton's Philsboat project is filling his shop. |

|

Propellor Pitch

THE VERY BASICS...Boat propellors are sometimes called "screws" because they basically work the same way as a screw. Screw propellors replaced paddle wheels pretty quickly in the early steamship days.

I suspect the first ones may have had blades that were continuous over a few revolutions, more like an auger. The motor guru added: "Francis Petit-Smith apparently conceived of the use of Archemedes water-lifting screw as a propulsion device. He built a full-size prototype, powered with a "screw" shaped much like a screw. While testing, an object in the water was struck, causing the a good prortion of the long "screw" to break off, and the resulting short section continued to push the boat, but at greater speed. John Erickson, designer of the Union ironclad Monitor, was also involved in these trials, and received much credit for the ultimate design of the propeller."

The English also led the way. They proved the point in the early 1800's by making two steamships identical except one had paddlewheels and the other screws. They tied them together for a tug of war and the screw boat easily out tugged the paddlewheeler. The motor guru adds: "The paddle-wheel powered HMS Electo and the propeller-driven HMS Rattler were the two ships in the Tug-of-war."

Anyway, if you take a screw with say 16 threads to the inch and run it into a board, it should take 16 turns to move it forward an inch because that is the pitch designed into it. Boat propellors work the same way, with a designed pitch. They proceed forward a certain amount with each turn.

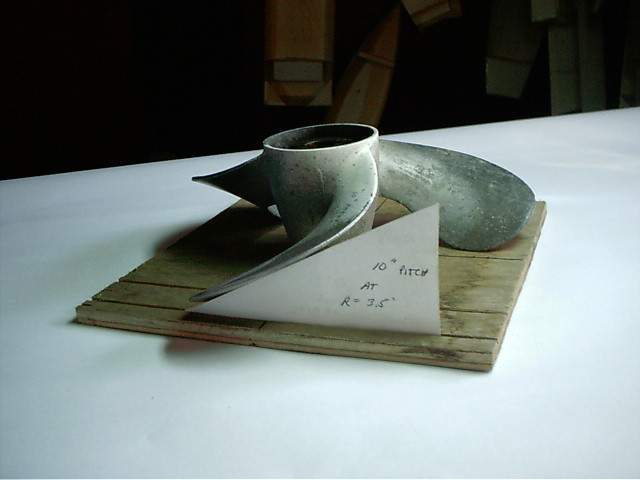

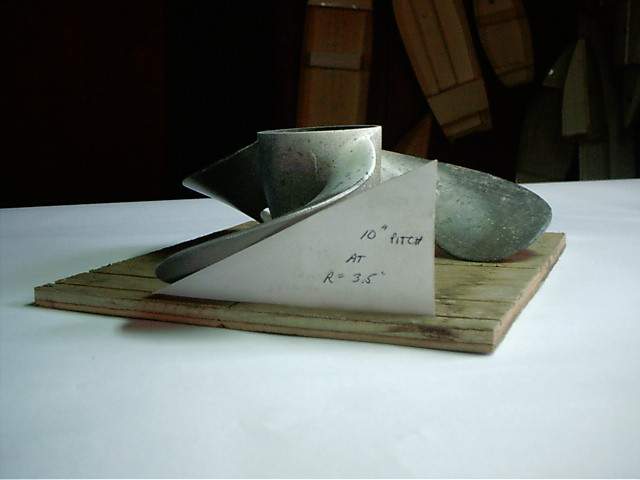

Here is a picture of a prop:

Let's say this one has a 10" diameter and a 10" pitch (actually a common size for a 20hp or so outboard). Look at point A which is 3.5" from the center. As the prop turns a revolution that point will travel pi times 3.5 times 2 = 22". That point will also travel forward 10" (by definition as a 10" pitch) with that revolution assuming no slip so the angle the props face moves through is 10 to 22 which is 24 degrees. Now look at point B which is 2.5" out from the center. That point will turn 15.7" with each rev (pi x 2 x 4.5 =15.7) but travels forward the same 10" as point A. So the prop face there moves through an angle of 10 to 15.7 which is 32 degrees. And so forth along the entire face so that you see as you move from the hub to the tip the blade twists to have a flatter angle. I would think that any effort to "repitch" a proper propellor would be a compromise because you won't be twisting the area near the hub as much as that near the tip.

"But," you say "I can tie my boat to the dock and run it full throttle and it won't move." True, boat propellors do "slip" (aircraft propellors too). I used to think of it like a car's wheels spinning on ice. That isn't the case with a prop in the water. The wide open motor tied to the dock is still putting out its full power but now the power is moving water instead of moving the boat. When I drive over a Mississippi River bridge I'll see huge towboats pushing a dozen big barges (they say over three dozen big barges below Cairo, the largest moving acreage on earth). Thousands of horsepower but no more speed than a jonboat with 10hp. Their wake is not that big but you don't want to boat behind one (or in front of one for that matter) because that big power produces a huge rolling "race". As they push forward a huge amount of water is being force backward and you can see it. With a light boat going full speed the situation changes to where the power goes almost all towards pushing the boat forward.

This year I hope to scope out the slip situation first hand. If you know the rpm of the propellor and its pitch you can figure out how fast it would be going with no slip. Then on the real boat you can measure the speed with a gps and the difference would be the slip. Max says he has a tach, I have a gps, we need to know the prop pitch and the gear ratio of the lower unit. Then for the ice to melt and boat testing.

That would satisfy curiosity for those of us who are easily entertained. But a more serious reason to measure pitch would be to match the prop to the boat. Let's say you have a 10hp motor that pushes a light jonboat 20mph and all is well because the boat's top speed and the engine's redline happen at the same time because the prop is correct. You put the same engine on a heavy shantyboat and now full throttle gives maybe 8mph. Sort of like taking the engine/transmission out of your Ferrari and putting it in your dump truck who's engine had the same horsepower. The power may be the same but your truck won't go 200 mph like the Ferrari did. In fact if the engine can't rev up to its power band it won't go as fast as the old truck engine/transmission did. (People who do a lot of biking with multispeed bikes know first hand of all the situations where you need to shift down to go faster.) So you would think the shantyboat installation would prefer a flatter pitch prop that will allow the motor to deliver its horsepower revs at a lower forward speed than the jonboat propellor.

MEASURING PROPELLOR PITCH...

Looking back to the picture of the ideal prop you see you can measure the pitch anywhere on the blade and should always get the same answer because if properly designed all sections of the prop have the same pitch. All you have to know is the angle of the face and the distance from where the angle measurement was taken to the prop's center.

Here is the simple gadget I made to do that.

Start with a 10" square of plywood. Draw crosshairs on it. In this case I cut a 1.5" diameter hole in the center to allow it to be used with props already mounted on the motors but the hole is better omitted otherwise. Then I cut narrow grooves out 2.5" and 3.5" from the center.

I cut out a bunch of angle templates from index card stock and labeled them for angle and pitch. They look like this:

So to measure the pitch of a prop you first place it centered on the plywood with its aft face against the wood because it is the angle of the aft face that is easiest to measure (because the aft face is usually flat). The center of the blade to be measured should be centered over the crosshair that passes over the grooves. Not always easy to do that as you see here with a "semiweedless" curved blade from an old OMC.

Next we slip the angle templates into the most appropriate groove until we have a match, like this:

I used the 3.5" groove here but with a smaller prop I would use the 2.5" groove. But remember that you need a different set of angle templates for each groove. Here is another view:

It isn't totally exact because the face of the prop often isn't exactly flat. (I think the "perfect" way to measure the pitch would be to get the angle that goes through the the tip of the leading edge and the tip of the trailing edge. )

There you have it. This old OMC prop measured out at 10 inches of pitch.

ORACLE

ORACLE, LIGHT ROWBOAT, 15-1/2' X 45" X 80 POUNDS

Oracle might have been called Roar3. It is a bit longer and lower than Roar2 so it looks sleeker. It is actually closer in shape to my Toto canoe. I'm pretty sure it is a visual improvement over Roar2. Hard to say if it is a practical improvement. Being lower sided it might seem less secure but then again my Roar2 has never taken water over the wale in the ten years I've had it and maybe I've been hauling around excess freeboard. Max Wawrzyniak of St. Louis made the prototype. We rowed our boats side by side on a good day recently. I'd say the Oracle was 1/2 mph faster all around going about 4 mph at cruise and 5+ mph on the gps at full effort. It should float two adults quite nicely.

I'd like to point something about the way I draw the line on many of my boats. I make card models of my designs which help me check the panel expansions and allow me to get a 3D check of the shape. The models are done in the same scale as the blueprint, in this case 1/8 and the model is fairly large. So I knew that Oracle has nice curves all around. But if you look at the end view in the lines drawing you see all straight lines! In a way this is a throwback to the original "instant" boats which had hull panels made from straight saw cuts. It is easy for a designer to make the jump to more flexible shapes, that is hull shapes which can look like about anything you might imagine being made from plywood. Back when I started drawing boats I noticed some of the nicest shapes in 3D had end views made totally of straight line segments. Don't ask me why. Not only does that give a nice shape, the designer's job is simplified. For example, with Oracle I might start by drawing the top view. Then I might sketch in the side view needing nothing more than an idea of what the stem, midsection, and stern will look like. Next I draw the end view which will include those elements connected by straight lines. In normal mechanical drawing it only takes two views to totally define an object. So without even drawing the side view of the boat the shape is defined. It only remains to go back and figure it out and adjust the top view, etc., etc.. Happy is the designer who gets it right the first time through.

Oracle is built with taped seams using four sheets of 1/4" plywood. No jigs, no lofting.

Oracle plans are $20 when ordered direct by mail from me.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

We have a Picara finished by Ken Giles, past Mayfly16 master, and into its trials. The hull was built by Vincent Lavender in Massachusetts. There have been other Picaras finished in the past but I never got a sailing report for them...

And the Vole in New York is Garth Battista's of www.breakawaybooks.com, printer of my book and Max's old outboard book and many other fine sports books. Beautiful job! Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat. But he has used it extensively on his Bahamas trip towed behind his Cormorant. Sort of like having a compact car towed behind an RV.

And a Deansbox seen in Texas:

Another prototype Twister is well along:

A brave soul has started a Robbsboat. He has a builder's blog at http://tomsrobbsboat.blogspot.com. (OOPS! He found a mistake in the side bevels of bulkhead5, says 20 degrees but should be 10 degrees.) This boat has been sailed and is being tested. He has found the sail area a bit much for his area and is putting in serious reef points.

AN INDEX OF PAST ISSUES

THE WAY BACK ISSUES RETURN!

MANY THANKS TO CANADIAN READER GAETAN JETTE WHO NOT ONLY SAVED THEM FROM THE 1997 BEGINNING BUT ALSO PUT TOGETHER AN EXCELLENT INDEX PAGE TO SORT THEM OUT....

THE WAY BACK ISSUES

15aug17, Taped Seams, Cormorant

1sep17, OliveOly Capsize Test, OliveOly

15sep17, Plywood Butt Joints, Philsboat

1oct17, Sailing OliveOyl, Larsboat

15oct17, Water Ballast, Jonsboat

1nov17, Water Ballast Details, Piccup Pram

15nov17, Scram Pram Capsize, Harmonica

1dec17, Sail Area Math, Ladybug

15dec17, Cartopping, Sportdory

1jan18, Trailering, Normsboat

15jan18, AF3 Capsize Test, Robote

1feb18, Bulkhead Bevels, Toto

15feb18, Sail Rig Spars, IMB

1mar18, Sail Rig Trim 1, AF4Breve

15mar18, Sail Rig Trim 2, Harmonica

1apr18, Two Totos, River Runner

15apr18, Capsize Lessons, Mayfly16

1may18, Scarfing Lumber, Blobster

15may18, Rigging Sharpie Sprit Sails, Laguna

1jun18, Rigging Lug Sails, QT Skiff

Table of Contents