Left:

JIM HUDSON'S PICCUP PRAM

Contents:

Contact info:

- Jim Michalak

- 118 E Randall, Lebanon, IL 62254

- Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1SEP98) This issue will continue with the sail thoughts thread. We'll look at bit at the workings of spars. Next time, about 15 September, we'll likely look at some more capsize testing, this time with Herb McLeod's AF3.

Eventually these sail thoughts will lead up to making a real sail. There is a site on the web at PolySail Home Page where materials for making poly sails are sold. I've never seen the materials myself but you might take a look.

MIDWEST MESSABOUT ALERT...The 7th annual Lake Monroe Messabout will take place at Lake Monroe, south of Bloomington, Indiana on September 18, 19 and 20. We'll be at the Paynetown Recreation Area. Bob Bringle is in charge at rbringle@iupui.edu.

|

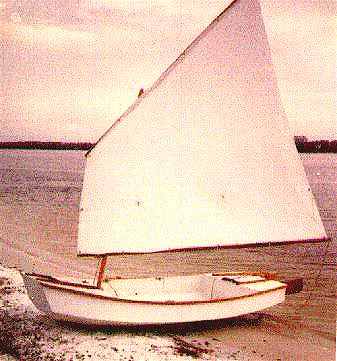

Left: JIM HUDSON'S PICCUP PRAM

|

|

|

|

|

|

I'll contiune the "sail thoughts" that I started a while back. This time will discuss the actions of spars a bit, especially with a look at deflections of spars used in simple homebuilt rigs and how they affect some things the sailmaker might do

Figure 1 shows an idealized version of the spars of a balanced lug rig. Here I've assumed that all of the halyard load is transmitted through the luff and leach of the sail. That's not totally true but in a well cut sail only the luff and leach will be tight if the wind isn't blowing because the sail is cut to have a loose pocket of draft in its center. But when the wind starts blowing the entire sail developes tension and the yard and boom are loaded by that cloth along their length. Anyway, I've shown the halyard with a nice round 100 pound load. What are the deflections of the yard and boom?

Figure 2 shows how to figure the deflection of a beam loaded as in Figure 1. The source of the equation is a book called Roark's Formulas For Stress and Strain. That book is a super cookbook for the stress analyst, the stressman's bible.

I think most of the elements of the formula are plain except for the "EI". E in an equation that predicts deflection is alway the modulus of elasticity, pretty much a spring rate for the material and it has units of "pounds per square inch" and has nothing to do with the strength of the material, only its stiffness.. It's a very large number. For aluminum E is 10 million. For wood E is about 1.5 to 2 million The length dimension "a" is always from the load "W" to the nearest end of the beam.

The "I" in the equation is the moment of inertia of the cross section of the spar. It has units of "inches to the fourth". Figure 3 shows how to figure the moment of inertia for square cross sections and round cross sections. As you see the I of both the square and round sections are related to the fourth power of the thickness of the section so a little increase in thickness gives a big increase in moment of inertia and thus in stiffness. For example a 1" diameter boom has an I of .05. A 1.5" diameter boom will have an I of .24. And we have increased the bending stiffness by a factor of 5! By the way, if you have a hollow spar, the I can be figured simply by taking the I of the OD of the tube and subtracting the I of the ID of the tube. For example, a round tube of 1.5" OD and 1" ID would have an I of .24 - .05 = .19. So the tube is almost 4 times as stiff as the 1" solid spar but only 26% heavier. So tubes are popular with those who can afford them.

Now, if you crank through all the equations for the yard assuming the yard is of wood and has a cross section of 1-1/2" square you will find the yard will flex over 3" under the 100 pound halyard load. (Actually the work was done with an applied load W = 70 pounds because the yard is tilted 45 degrees and only a 70 pound component of the 100 pounds is acting perpendicular to the beam.) So what?? It's actually a big deal to the sail maker. If you recall the essay on sailcloth you might remember that a sail 10' wide with a 1' draft will actually have an arc length of about 10' 2-1/2" across its middle. So the sailmaker will sew in the extra 2-1/2" to supply the draft. That might appear as a bulge of 1-1/4" along both the foot and head of the sail. So if the yard and boom are straight, the proper amount of draft will appear in the center of the sail. But if the yard flexes 3" under the sail load, it will pull all the draft out of the sail! So one of the problems the sailmaker has to face is to guess at the flexing of the rig. In this case he might supply the head with 3" + 1-1/4" = 4-1/4" of curve at the head of the sail.

But then again he may not supply that much and here is why. One nice thing about a lug rig with a flexing yard is that as shown above the flexing will pull draft out of the sail when a large sail load is applied. In many cases that might be considered to be good because it will flatten the sail in high winds. On the other hand, if you feel your lug sail does not have enough draft in high winds, one thing you could try to cure the situation might be to increase the size of the yard.

If you run the numbers for the boom, assuming the same 1-1/2" square section, you will find the flexing is small compared to that of the yard, about 1/2". That's mostly because the boom is shorter and because it is supported closer to its ends, near where the loads are being introduced. In fact it is possible that the boom will flex towards the sail under a large load and add draft to the sail in high winds.

Figure 4 shows a free standing sharpie sprit rig. The sail of a sharpie sprit can be pretensioned by tightening up the snotter which is the tackle on the mast end of the sprit boom. How much will the mast flex?

Let's say the mast here has a 2" square cross section. And let's say the snotter tackle is a 2 to 1 thing so that the skipper pulls on the rope with a 50 pound tug and it results in a 100 pound preload on the sprit boom. The boom is in compression. You can imagine the mast deflecting under the load like a bow and arrow. Crank through the equations and it turns out the mast will flex over 3", assuming the mast is 2" square from top to bottom.

But few masts are made that way. Almost all are tapered and the taper greatly affects the deflection. As above, the sailmaker needs to know the deflection so he can allow extra material in the form of a bulge on the luff that anticipates the flex of the mast. Jim Grant of Sailrite kits recommended that the sailmaker predict the flex allowance of an unstayed mast by placing the mast on sawhorses and place a weight equal in pounds to 1/3 the sail area in square feet at the center of the mast. Then you stretch a line along the mast and measure to it a various stations along the mast and make a plot of the mast flex. Then that flex is added to the draft allowance of the sail at the luff. Usually the flex allowance is a lot more than the draft allowance!

WHAT I THINK IT ALL MEANS....

To put this all into perspective, I doubt if anyone except a Cup boat has the resources to do a meaningful analysis of the deflections of the spars of the boat. Even then, I would not trust the results of a paper analysis unless it was backed up by a wealth of real life experirence. There are so many variables. But for us little sailors it is worth while to get a handle on how much the rig is flexing and what effects the flexing is having on the set of the sail.

NEXT TIME...

We'll look at capsize tests of Herb McLeod's AF3.

PICCUP PRAM

ROW/SAIL PRAM, 11' X 4', 90 POUNDS EMPTY

Someday I may get to put my full catalog on the net. For now I'll put one design in each issue.

PICCUP PRAM

I still have the original Piccup, now about 10 years old. For what it is supposed to do I still haven't thought of anything better, although I've tinkered with the design a time or two. The photo above shows the original at Pensacola's Big Lagoon. The boat is not white anymore. It's camouflage green and brown, much easier to apply and take care of but a lot less yachty. And the sail rig is now larger and of polytarp. But that's it. The actual hull structure is unchanged after ten years. I might add that the hull is built of exterior plywood and stuck together with glass tapes set in polyester resin. It's stored indoors.

Here is the write up in the current catalog:

Piccup Pram, the first of my designs to be built, was originally to be the best boat I could slide into the bed of my pickup truck. Now I usually cartop her.

When I drew Piccup I had one eye on a Bolger Nymph and the other on a Herreshoff Marco Polo tender. For her size and weight she is very roomy and able to take rough going. The flat pram bow provides capacity equal to a pointy bow hull two or three feet longer. Her multichine shape gives soft shoulders which prevent waves from rolling her as they would a flattie.

Her balanced lug rig, now enlarged to 68 square feet, stows rolled up in the cockpit while her pivoting leeboard and kickup rudder raise instantly for rowing. These lug rigs can be built effectively from ordinary materials including discount store polytarps. Piccup will row 7 miles in two hours in calm conditions and will rig for sail in a couple of minutes if the wind pipes up.

Piccup has a flat bottom panel that keeps draft to 6" with two adults aboard, allows level beaching, and is big enough for a sleep spot. I've camped in Piccup many times. The ends have buoyancy/storage chambers of about 6 cubic feet each - enough for two or three days' supplies for someone used to roughing it. I don't take a rain tarp, being careful to camp on a no-rain forecast. The lug sail can be rigged as a rain fly to a certain extent. A bug net is mandatory.

Construction is taped seam 1/4" plywood, 5 sheets required. All parts are cut to the shapes shown on the drawings and pulled together with twisted wire loops. No jigs or lofting required. Gaps and bevels are of no consequence. Seams are filled with putty and the wire twists are snipped off. Then the seams are locked together with fiberglass strips set in epoxy or polyester.

Plans are four blueprints with complete instructions for $20

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. (If you order a catalog from an internet page you might state that in your letter so I can get an idea of how effective this medium is.) Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currancy that I can admire but not spend.) I'm way too small for credit cards.

Usually when a design from the Catalog of Prototypes starts getting built I pull it and replace it with another prototype. So that boat goes into limbo until the builder finishes and sends a test report and a photo.

Here are the prototypes abuilding that I know of:

Sneakerbox: Here is a boat that was in the prototypes catalog only a short while so most folks won't know about it. It's an "instant" version of the 12' garvey box that appears on page 65 of Chapelle's American Small Sailing Craft, a book you should have in your collection. Al Tilley Jr in Pennsylvania has completed the first one (minus sail rig) and has sent the above scan. I hope to have a full review in an issue or two.

Sportdory: Word from Dave Burdecki in California was that he had his completed but no word of the launching. You can check out John Bell's Sportdory progress by clicking here .

Skat: the prototype Skat builder is Roger Palaski. Up until now he was a mystery man know to me only as "Roger", his Skat plans bought for him by someone else. Then I find out he has his own web page with the Skat construction photos on it! Skat is a small somewhat traditional 12' cat boat with a gaff rig. Even has a centerboard, the only boat I've ever designed with one! See Roger's progress by clicking here.

Nothing new on the Texas IMB. Click here to visit Tim Webber's page and see some photos of the IMB as of a few weeks ago. Then poke around Tim's web page a bit.

Fatcat2: There is an old timer (80 years +) in Minnisota who has completed the hull of a Fatcat2. Fatcat2 is a simple 15' x 6' catboat, gaff rigged and multichined. I think the sail rig will be done this coming winter.

Shantyboats (archived copy)

Herb builds AF3 (archived copy)

Hullforms Download (archived copy)