JOHN APPLEWHITE'S HARMONICA

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Oct99) This issue presents thoughts about boat costs. Next issue, 1Nov99, will show how to figure a center of gravity location for a boat and what it means.

|

|

Left:

JOHN APPLEWHITE'S HARMONICA |

|

|

Boat Costs

BIG BOATS - WHAT THE SALESMAN FORGOT TO TELL YOU...

Where I live, near St. Louis, there are only a small handful of million dollars boats. But there are a good number of motor yachts in the $300,000 range, usually about 50' long, three stories high, and with twin V8 engines. My advisor on such matters is the Old Insurance Man, or OIM for short. These yachts each come complete with accountant and lawyer, of course, so figuring what one really "costs" can involve a lot of imagination. But the OIM points out that anyway you pay for it, the 300K could be in the bank earning a secure 6% with no worry or effort on your part, so the owner is losing about $18,000 a year there. The OIM says insurance around here typically is about $1500 per year. Slip fees here would be maybe $300 a month for such a boat, could be a lot more in some marinas, so that is another $3600 a year. So without ever leaving the dock or doing any maintenance you are at about $23000 per year you would be out for having the boat, about $65 a day so far. The OIM pointed out one owner who sold his 50 foot $300K boat and got a new 53 foot similar boat for $1.3 million. A better newer boat, no doubt, but it still looks like someone paid a million dollars for a 3 foot boat. The OIM said the man suffered from a medical condition called "Biggest Cock In The Jungle Syndrome".

DOWN AN ORDER OF MAGNITUDE...

Boats costing $30,000 are actually pretty common. A deluxe bass fishing boat will be in that range and if you see one going down the highway behind a fancy truck you are looking at $60,000 worth of stuff. Larger inboard runabouts like family skiboats can also be in this range, or more expensive, and you see them all the time. I don't know of any new cabin cruisers with bathroom and microwave that cost less than this, most are a lot more. These boats are usually financed by the dealer like a car except the loan will run for maybe 15 years. Anyway you pay for it the OIM would point out you are losing at least 6% or $1800 a year in potential interest. Insurance might be $150 a year. Slip fee might run $100 to $200 a month around here although you might get by with trailering. So that is about $3800 a year, or about $10 a day whether you use it or not.

DOWN ANOTHER ORDER OF MAGNITUDE...

There are lots and lots of boats out there in the $3000 range. I suppose that might include most used fishing boats and smaller sailboats. (A look at a local dealer showed no new boats for that - the cheapest rig they had was a fine but plain aluminum jonboat, about 14' long, with a new 10 horse four stroke motor, all on a big wheeled galvanized trailer, for $3800.) The usual loss in potential interest would be about $180 a year. Most likely you would trailer a boat like this and slip fees would be no factor. Your home owner's insurance will often cover a smaller boat at no extra charge and you might skip any extra insurance. So the costs here are usually pretty acceptable. I've had boats in this range and my only thought about boating costs are the immediate things like registration of boat and trailer and maybe fuel costs.

HOMEBUILT BOATS...

Now we're getting to the main subject of the essay: I want to look at the costs of building a plywood boat and explain why they vary so much from builder to builder. When someone asks me "how much will it cost me to build that boat?" I usually don't give an answer anymore. (An even more loaded question is "How many hours will it take me to build that boat?") As an example of the varying costs I'm going to use Harmonica, the featured boat of this issue, even though Phil Bolger would be very quick to point out that it is questionable to spend a lot on a boat that was designed to be cheap. Here is a photo of Harmonica:

Plywood is the main element of this boat and Harmonica needs needs six sheets of 1/4" plywood and four sheets of 3/8" plywood. The cheapest boat would use exterior pine plywood from the lumberyard. I think that plywood costs $12 a 3/8" sheet and 1/4" sheet is not available in pine at my lumberyard. The extra weight in using all 3/8" plywood might be about 80 pounds and this boat could handle that. So that is about $120 worth of cheap plywood.

Perfect plywood per BS1088 turns out to be cheaper than I thought. 1/4" Okoume sells for $69 a sheet and 3/8" for $79 a sheet. So the bill here would be $730. Okoume is said to be quite light in weight. A denser harder perfect plywood might be Khaya which is $95 a 1/4" sheet and $119 a 3/8" sheet for a total of $1046 for Harmonica. Just for this argument let's say the perfect boat builder uses Kyaha for the bottom, four sheets of 3/8", and Okoume for the topsides, six sheets of 1/4", and that all figures to be $890.

There is some framing lumber involved too but I don't really know how much. But as I recall clear lumber costs about three times as much as common lumber. Let's say the cheap boat uses $50 of common lumber and the perfect boat uses $150 in clear lumber.

As for glue, this is a tough one. The cheap builder might get a $10 bag of Weldwood plastic resin glue from Wick's Aircraft and should have enough. Another reasonable choice might be some tubes of waterproof construction glue, let's guess 8 tubes at $3 a tube?? The perfect builder is going to use epoxy and will buy a lot of it because he plans to coat the entire boat and glass the outside. Let's say he gets 5 gallons at $50 a gallon, or $250 worth. (I'll admit I have no idea of what he will really need but it will be more than a gallon and less than ten.) The cheap builder will have to get some epoxy, too, to armor his chines. So he gets one gallon at $50 and has maybe $75 in adhesives in his boat.

As for fiberglass supplies, the cheap builder is only going to armor his chines and bottom seams so he gets by with a $20 roll of glass tape, 50 yards worth. The perfect boat is glassed all outside so he gets his roll of tape plus maybe 20 yards (I'm guessing again) of 6 ounce glass cloth at $5 a yard for a total of $120.

As for fasteners, the cheap boat might use lumberyard galvanized nails and the perfect boat use bronze boat nails. But I would suggest the bronze nails for everyone as they are truely superior and you don't really need that many. Another guess at maybe $15 for the bronze nails to build the whole boat.

OK, now we've got the structure done. Let's paint it. The cheap boat might use a gallon of good latex primer and another gallon of good top paint, about $40 worth. The perfect boat tries premium brushable oil based marine paint at $40 a gallon or $80 total.

There will be other costs in fitting out but I won't get involved with those.

Let's add it up:

Item Cheap Boat Perfect Boat Plywood 120 890 Lumber 50 150 Glue 75 250 FGlass 20 120 Nails 15 15 Paint 40 80 Total $320 $1505 So the premium boat costs almost five times as much as the cheap boat. I may be wrong with my estimates but I can tell you this factor of five is no surprize to me. I've seen it over and over. I might also add that the $320 cheap version is pretty believable to me too. My records show I spent $406 on the hull of my prototype AF4 and it uses similar construction and materials to the Harmonica. I used $20 exterior plywood instead of the pine exterior plywood and think it was worth it in that the quality meant there was no waste and the smooth surface required no paint preparation.

I'd like to also point out that I never really have to steer anyone towards cheap or premium construction. Everyone seems to know from the start exactly which way they want to do it.

IS THERE A MIDDLE GROUND?...

My first little boat was done with premium materials but my second one, the prototype Bolger Jinni, was a lumberyard boat all the way. I wrote to Phil Bolger admitting that and his response was that there were only two ways to build a boat - total cheap all the way or gold plate all the way. Nothing in between made sense.

I don't know if things are quite so simple, though. Fir marine plywood would likely cost midway between the cheap exterior ply and the premium ply and in Harmonica's case you might save a few hundred dollars over the premium boat. Looking at my guesswork it would appear that glassing the exterior costs you maybe $300. I think in some cases it might be worth it. Glassing the exterior is also a lot of extra work but I've seen some fine examples that really held up over the years.

You do have options.

NEXT TIME...

I'll show how to figure a center of gravity.

Harmonica Again

< WIDTH="350" HEIGHT="227">

HARMONICA, MINI SHANTY, 13' X 5', 400 POUNDS EMPTY

I reviewed my Harmonica design a few weeks ago but got these photos plus a nice letter from a second Harmonica builder, John Applewhite of Gainesville, Fl. When John wrote me way back when about looking for a small shanty boat he said that he was experienced with electric boats and also with a big shanty, 28' long as I recall. Here is the big shanty:

He said the big one was a bit much for solo boating and something like Harmonica would be better in that case. He calls his Harmonica Steel Will. Here are parts of his last letter:

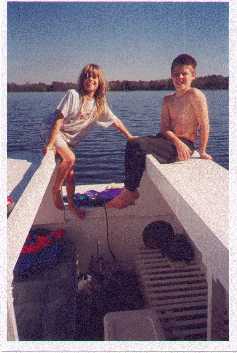

"...The entire family (two adults and two children) has spent the night on Steel Will. I put 1x2's between the slats in the two forward bunks and create a single bunk that is five feet wide. We have found that the thick cushions sold to cover lawn furniture make very adequate mattresses for boats.

< WIDTH="237" HEIGHT="350">

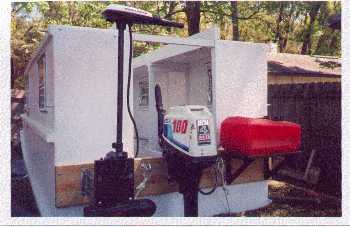

"We use the 3 hp MinnKota electric as much as possible. In the picture facing aft the two golf cart batteries are just behind the bulkhead on the port side. You might notice that I used two 2x4's at the bottom of that bulkhead, the symmetry was too perfect.

"The only time the electric motor fails to perform satisfactorily is going upstream in a river, then Mr Honda has to be used. The 10hp Honda is far too much for this boat, but it is all I have on hand. A five hp Honda would be perfect.

"I would be very interested in hearing how others have covered the center walkway during rainstorms. I have three PVC pipes that bend in a U shape over the cabin area of the boat. I throw a tarp over the pipes and hold the whole mess together with elastic tie downs. With the tarp up it looks like a waterborne Connestoga wagon. It works and allows standing head room, but it really flops in a breeze and I am convinced that it might fail some dark stormy night."

Well, John is actually on the cutting edge of this walkway tarp problem. I used to use plywood panels but converted to a simple cover made of polytarp that snaps to the side and is supported at intervals by small diameter PVC pipes which bow only slightly - I don't have standing headroom with the tarp on but it does seem snug and you can trailer down the highway with it on. Almost anyone who has tried a plywood cover for the walkway has gone to a softcover. One man warned against using Sunbrella like fabric which is apparently not sufficiently waterproof for a flat cover.

Harmonica plans are $25.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Here are the prototypes abuilding that I know of:

Jonsboat: I suspect a few of these have been built but I've never gotten a report. Here are photos of one being built by Chuck Leinweber of Duckworks Magazine

< WIDTH="246" HEIGHT="168">

Mayfly12: A Mayfly12 is going together up in Minnesota. The decks are on and he's into the sailing bits. By the way, the sailing bits on almost any sailboat large or small consume about half of the effort in labor and materials. Just when you thought you were about finished!

AF4B: A builder in Virginia is building AF4Breve, a 15.5' version of the 18' AF4. I tried to talk him into building the 18' version but he had two very good reasons to go shorter - a short trailer on hand and insufficient building space for the larger boat. The AF4B is essentially a "scrunched" version of AF4 but comes from a whole new set of drawings. The prototype is in the final building stages where the sanding and filling and painting seem endless.

AF2: An AF2 has been started in Oklahoma that should be close to the plans. Sides cut and bent around the bulkheads and forms right now. This is not an overnight project.