HERB MCLEOD'S AF3 (WITH DOG)

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1Sep99) This issue will show construction photos of some AF3's and present some interesting sailing tests of AF3's up in Canada. Next issue, 15Sep99, will be an important rerun of how to recover from a capsize in an AF3.

MESSABOUT NOTICE...

The 8th annual Lake Monroe Messabout will take place on September 24, 25, and 26 at the Paynetown State Recreation Area on Lake Monroe, about 10 miles south of Bloomington, Indiana. There is no schedule of events. Typically, people arrive on Friday evening or Saturday morning. The Messabout begins to dissolve Sunday afternoon. I hope to see you there but I'm not in charge of this one. Bob Bringle is at rbringle@iupui.edu.

ANOTHER MESSABOUT NOTICE...

Craig O'Donnell will be hosting his Sassafras Messabout at Betterton, Md, on September 18 and 19. Contact Craig at dadadata@friend.ly.net. (Craig told me this one is actually anti-organized.)

|

|

Left:

HERB MCLEOD'S AF3 (WITH DOG) |

|

|

MORE AF3'S

Over the past few months I've been getting photos of ongoing projects including a few of AF3's. I decided to put those together into one article. As a bonus I received from Canada news that a second AF3 was sailing beside Herb McLeod's prototype with interesting possibilities of testing.

CONSTRUCTION PHOTOS...

Everyone wants to see some of these. The first shown here are from Pierre-Yves Gabi in Switzerland:

What you see here are all the pieces that are required to start the assembly of the boat. On the bottom are the four panels that form the two sides, still to be joined by butt straps. Above them are, from left to right, the main cabin bulkhead, the aft cockpit bulkhead, the forward cabin frame wrapped around the transom, and two temporary formers made of plain lumber. The plywood appears to me to be birch, hard to get around here.

When you start putting the pieces together they will look like this from the stern:

This is how some flat iron skiffs were made in the old days. If you've been reading perfectionist books you will be looking for a building frame or ladder frame underneath it all but there is none. It's assembled right on the floor, starting right side up, by wrapping the sides around the other parts. You need to have good centerlines marked on all the pieces and a good centerline or a taught line on the floor to keep all the bulkheads, frames, etc., in a row. Then you need to level those pieces crosswise to prevent hull warpage. But sometimes you can just eyeball all the cross pieces to make sure things aren't twisted. Usually if your pieces are accurate it will want to go together right. You may have to brace things to keep them aligned. I notice in the above photo that the stern seems lashed to the side wall. As the assembly progresses and more pieces are added it will stiffen quickly.

Here is another construction photo, this one by Frank San Miguel of Connecticut. His boat was about at the same stage as Gabi's. In this photo you can see all the cross pieces in place. You can also make out a rope used to pull the stern sides together. Frank has a nice flat floor to work on but the job can really be done anywhere on a pair of leveled sawhorses.

Here is the bow of Frank's boat. You can make out the temporary frame of plain lumber towards the right, the forward cabin frame, and the stem piece. You can see the rope used to pull the sides together during the assembly and some clamps near the stem to really draw the pieces tight there. You can also see that the sides rest here and there on pieces of wood which can be used to tweak the alignment and steady the assembly.

There is one other thing worth noting here. I think Frank is using exterior AC fir plywood although it might be real marine ply. I think he has filled the C side flaws before assembly, always as wise thing to do and a great time saver. He has put the A side outside but another time saving ploy is to put the filled C side on the outside where it is much easier to sand after assembly.

NOW, OFF TO EDMONTON...

Here is a new photo of Herb McLeod up in Edmonton, Alberta, with his dog Maggie looking out through the oar port. I wanted to show this photo again to demostrate the size of the boat. It's not huge. It's 16' long and 5' wide and the cuddy cabin is really a pup tent sort of volume. Without Herb and dog in this photo the boat might appear larger than it really is. I've had letters where someone wants go cruising in one with some buddies but for that you will need something about twice as large. You can also see there is no room on the stern for a motor. The lower part of the sharpie sprit rig and the pivoting leeboard show well in this photo.

Now here is a photo of a new AF3 built by Herb's friend Gordon, sailing on the same lake but on the opposite tack. In this view the leeboard is on the other side and not visible, same with the sprit boom.

Gordon's boat has no windows. That's not a big factor but if you start camping in one of these you will want them. Things human and otherwise can prowl around you while you are in the cabin and being able to see what they are without showing yourself is nice.

Also you can see that with one person on board that she trims a bit bow high. The stern is still not dragging through the water and I see no harm in it. My old Jinni was exactly the same.

SAILING TESTS...

When Herb wrote me about Gordon's boat he added a lot of good info:

"On the technical side I have changed to the sail plan as was drawn. The boat sails better as the center of effort is now a foot lower. Helm control is the same, a slight lee helm in light wind. One interesting thing that would happen with both the old and new sail plan is, occasionally when tacking I would stall the rudder and the boat would sail crabbing along with the tiller pushed fully over. To correct it I would let the sheet out straighten the tiller to get it working and then the sheet in once my speed was up.

"Also your sail plan is better because the lift is not killed when changing tacks like occurred with my other leg-o-mutton sail. Thus I now can toss the curved boom and use a straight boom that is easier to transport. Another bonus to get good sail shape I do not have to rig the sprit boom so high up the mast so no longer have to stand on the deck to complete my sail adjustments. i.e. dryer :-)

"We also changed back to the lead-weighted rudder and again you are right it works better than my bungee cord device to sink the rudder.

"Gord's boat has the full-length leeboard and I have the shorter one. There is no difference in speed, or pointing ability. In light winds the boats are very evenly matched (we have not seen any heavy winds yet). The only difference that I can tell is my board does not pop up as often as Gord's does.

"I have a round mast that rotates in the step and partner and Gord built his as you have drawn it. Again there is no difference when we are sailing but mine does weathercock better the sheet is released. Gord's boom/snotter tends to bind up on the mast a bit after it swings past 90 degrees.

(The note about the different leeboards caught my eye. It turns out the Herb's is 44" long and Gordon's is 54" long, per the blueprint. But they found no difference in performance. That can happen but don't get the idea that the leeboard size is not important. I've gotten letters from other boaters where we solved problems by making the leeboard larger and my own Piccup Pram sailed better after enlarging the leeboard.)

I retuned this letter to Herb,

"I take it that your two AF3's are more or less identical except for the above notes. Are the sails identical too? If so you are in a position to make a very interesting test. Sail the two together side by side for a few hours, one with the sprit boom rigged "righty" and the other rigged "lefty". See if the interference of the boom makes any diff. I've never seen this test done before. You will be the first. A number of years ago we did this test with my Birdwatcher vs. a Dovekie. The boat with the boom on the upwind side of the sail (ie no interference) always had the advantage at least on that day with very light winds. But those two boats are quite different. Normally I wouldn't tell you the results of that test so as to not influence your thinking but I'm sure you will be objective. "

Herb replied,

"The boats are identical except that Gord's is about 30 pounds heavier because he made a thicker bottom. I make up for it by carring about 30 pounds more junk. We have both found that if we carry a 50 pound bar of lead in the bow the boat takes a less nose up attitude when sailing solo and lesssens the pounding. When we are next together on a light sailing day we will try the "lefty" and "righty" experiment and I will let you know what we discover."

Then a week later came this letter:

"Went sailing with both AF3's today. The conditions varied from fog to sun with winds from 9 to 24 Km/hr (6 to 15 mph) temperature varied from 18 to 24C. When one small storm cell passed through the winds were probably considerably higher. We went sailing for 6 hours and I rigged my AF3 as a "lefty" and Gord left his as a "righty". The boats were sailed with full sail (no reefing). Both sails were made at the same time by the same sail maker and as close as we can tell are identical and set on the masts in a similar fashion.

"Results: At the wind speeds we had we could not detect any discernable difference between the boats in speed on any point of sail, on either tack, and we tried them all. Also there was no difference in pointing ability on either tack (we were consistantly tacking to 90-95 degrees on my compass).

"I would also like to note that the new sail handled today's wind much better than my old sail as the center of effort is a foot lower. This made keeping the boat up much easier.

"One change Gord is going to make as a result of this is he said that he is going to cut 10" of his leeboard. One thing I would do different next time would be to build a square mast and keep it simple.

"A second change we will both make will be to get rid of the notch on the back of the rudder as it all too often hooks the sheet as you tack or jibe.

"Well my vacation is over and I am back to work tomorrow. I will let you know how my modifications to the RB42 work out.

"Herb"

I thought that was really a good test. There seems to be no real effect of "sprit boom interference" and all those efforts with curved booms or wishbone booms are wasted? It seems so. By the way, the notch in the rudder Herb refers to is there to allow the tiller to be swung back parallel with the rudder so it takes up a lot less room in storage. Not a factor perhaps on a trailer boat but important on a cartopper where the rudder assembly has to go into your trunk.

Many thanks to Herb and Gord for the test! It will be the topic of endless discussions and arguments and become a legend!

NEXT TIME...

I'll finish the AF3 lore with an important rerun from last summer of Herb's AF3 capsize tests.

AF3

AF3, CUDDY SHARPIE, 16' X 5', 250 POUNDS EMPTY

The AF3 (the original design study was called "Alison's Fiddle") prototype was built by Herb McLeod of Edmonton, Alberta, with 70 hours of labor. He used spruce exterior plywood made at the plant he has to drive past on his way to the lumberyard.

The sail rig is the exact one I used on my old Bolger Jinni and it also found its way onto the Pencilbox design. I align the sail area directly above the trailing edge of the narrow leeboard on sharpies. If weather helm becomes a problem (hardly ever happens) you can dial it out by sweeping the leeboard aft. Traditional teaching would have the sail much farther forward but that guarantees lee helm in a boat like this. I'll bet the old rule about "lead" in sail layouts applies well to the sharp deep cutwater hulls of traditional planked boats.

Also I've shown external chine logs on AF3 and all my sharpies. They are an easy, quick, and strong bottom attachment, but many can't accept their looks. Use traditional interior logs if you wish. Better yet, use epoxy/fiberglass tape chine joints with a healthy interior radius. That makes for a really clean looking boat and the worst rot area in a wooden boat, that chine log, is totally eliminated.

AF3 uses six sheets of 1/4" plywood and two sheets of 1/2" plywood. Plans are $30.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Usually when a design from the Catalog of Prototypes starts getting built and is close to launch I pull it from the catalog and replace it with another prototype. So that boat often goes into limbo until the builder finishes and sends a test report and a photo.

Here are the prototypes abuilding that I know of:

Jonsboat: I suspect a few of these have been built but I've never gotten a report. Just got word of at least one more going together and hopefully we'll get a photo and a report.

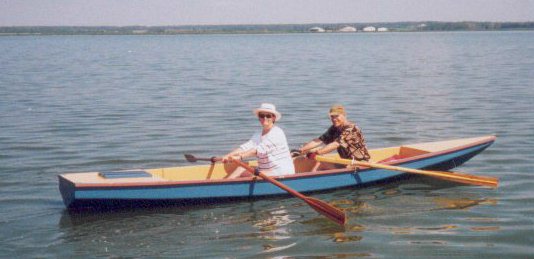

RB42: This is an 18' rowboat meant for two. Herb McLeod up in Edmonton has it completed. Imagine the Oracle shown in the 1may99 issue stretched to 18' and you have it. Here is a photo of its first time out. In a few issues we'll have a full report. Right now Herb is tinkering with the skeg and oarlock locations to fine tune it. RB42 plans are $20 if you are interested. Six sheets of 1/4" plywood.

Mayfly12: A Mayfly12 is going together up in Minnesota. The decks are on and he's into the sailing bits. By the way, the sailing bits on almost any sailboat large or small consume about half of the effort in labor and materials. Just when you thought you were about finished!

AF4B: A builder in Virginia is building AF4Breve, a 15.5' version of the 18' AF4. I tried to talk him into building the 18' version but he had two very good reasons to go shorter - a short trailer on hand and insufficient building space for the larger boat. The AF4B is essentially a "scrunched" version of AF4 but comes from a whole new set of drawings.

Herb builds AF3 (archived copy)

Hullforms Download (archived copy)