AF4's at Carlyle Lake. Mine in the back and Max Wawrzyniak's in the foreground.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15may01) This issue suggests some answers to the question "Why Build A Boat??". Next issue, 1jun01, will rerun the very important issue of Sail Area Math.

The 12th ANNUAL MIDWEST HOMEBUILT BOAT MESSABOUT...

... will take place on June 9 and 10 at the Gun Creek Recreation Area at Rend Lake in Southern Illinois. Take exit 77W off I-57, head towards the golf course and you will see the signs. Lots of people arrive on Friday and leave early on Sunday. The camping fee is $10 which includes the ramp fee at this Corps of Engineers facility. There is no schedule of events. We have a pitch in dinner on Saturday evening.

David Routh has posted several pages of photos of the April Lake Conroe, Texas messabout at www.shortypen.com (where you can also buy special short pens to keep in your wallet).

|

|

Left:

AF4's at Carlyle Lake. Mine in the back and Max Wawrzyniak's in the foreground.

|

|

|

WHY BUILD A BOAT

WHY BUILD A BOAT??

People have been building boats for thousands of years. If you look at the boats of old, such a Pharoe's barge, or a Viking's longboat, you might see that even the old ones aren't so simple. Even a dugout canoe requires a special tree and special experience.

But over 200 years ago saw mills began to turn out affordable boards, long and straight and clear, better in fact than we can get today since the good trees got chopped down faster than new ones can grow. With the new boards boat building perhaps became less of an art. You might build a boat without being the son of a boat builder or without serving a long apprenticeship. Common men began using boards and nails to put together skiffs and punts and sharpies and scows with ordinary tools and common house carpenter methods.

About 100 years ago panels made of thin wood laminations stuck together with water resistant glue made the scene and the material became quite common in mass produced boats by World War 2. Indeed, the war brought on a great expansion of activity and new materials and of men who had become well practiced at trying about anything. Plywood became perhaps the most common material used to build small boats, backyard or factory, from then until about 1960, when plastics and fiberglass became developed.

But plastics were usually unsuited for a one time boat builder for several reasons. Plastics were usually messy and toxic and usually required elaborate molds to make even one successful boat (although once the mold was made many copies of the boat could be easily made). And plastic panels must be thin to keep weight in check since the plastics are about twice as dense as wood. So smaller plastic boats usually require elaborate stiffening methods to keep the plastic panels from flexing excessively.

For the most part it is still that way today and plywood is often the best choice for the backyard builder. Designers in the last thirty years have gotten good at making the boats even easier to build - by defining the shapes of all the panels in the boat so the builder can cut them out directly and assemble them, unlike old-time boat building where the builder starts by drawing the lines of the boat full sized (called lofting), making a temporary skeleton or form or mold of the hull, and fitting the wooden hull surface in trial and error fashion. Not to belittle the old fashioned method of doing things - an experienced builder could do all that quickly and reliably and produce nearly any shape of boat, even more so than with modern jigless plywood construction.

But that's not the sort of goal I have here. The goal here is to get a good useful affordable boat built by a man with no boat building background. It has been done many times.

ARE YOU GOING TO SAVE MONEY??

You won't always save money by building your own boat. There are two reasons.

First, many fiberglass and aluminum hulls are massed produced in a scale beyond imagination. The materials are bought in large quantities at rock bottom prices and the labor so planned and routine that little thought is needed on the builder's part, such that it is all done quickly and right the first time. I suppose overhead costs are high but still some of these truly mass produced boats are pretty inexpensive new.

On the used market these boats can be cheaper than your cost of materials. That becomes especially true if the used boat is already rigged and equipped with all the doodads that you might need. A really simple example might be a used 16' jonboat for fishing. Around here right now a boat like that on a trailer complete with outboard and ready to go, everything maybe 15 years old but in good condition, might sell for $1000. (Brand new the same rig might sell for $4000 and only the motor technology has changed in 15 years.) If you are starting from scratch having to buy a trailer and motor and doodads, you won't be able to build a similar boat and keep the total cost to that.

By the way, estimating costs for a backyard boat is very difficult. If you are a craftsman you might use premium materials and they might cost three to ten times as much as the common lumberyard materials that I might use for a personal boat that I intend to give hard use. So one man makes a row boat for $100 and the next guy makes the same boat for $1000. It happens all the time. And I think both builders get exactly what they wanted, one of the advantages of building your own boat.

But getting back to the buying used argument, I think it is especially true for larger boats like cabin sailboats over 20' long. Many boats like that have been manufactured over the years, used for a year or two and then put into storage. Many marinas have a long row of these unfortunate orphans that haven't been in the water for years. Sometimes the owners visit once a year and pay their storage fees. Sometimes they give up and the yard tries to sell the boat for the back fees. The point is that you might get a 22 footer for three or four thousand dollars, complete on a trailer with a motor and sails. You could never build something like it for that. You would be doing the world a favor by buying it, scrub it clean, replace the cushions and trailer tires and lights, and go boating!

MAKE A BOAT THAT NO FACTORY MAKES!

One problem with boat factories is that they usually only make what is really popular at the time. And if you want something different you need to make it.

A really good example nowadays is almost any real rowing boat. There are some racing boats in fiberglass made on a limited basis, but good general purpose rowing boats aren't made in factories right now. But a good rowing boat is a pretty easy and inexpensive home project that will get a lot of use.

Another example might be small solo canoes. Big family canoes are a common factory product, but not so with the little ones. Another easy home project that can see a lot of use.

In the sailing category a good home project might be a dinghy. They aren't popular with factories. Dinghies take up little room and materials and labor, although they are limited in their abilities. Still, they can be a very good first project that leads to a larger boat since they give you practice with about every element of the larger project. And very often the situation is that after you get the larger boat done, you end up using the little one most.

A boat in the 12' catagory can also be a good candidate for the backyard shop. Again, good ones were never popular with factories. Real cheap factory ones were once popular, mostly foam castings with perhaps an ABS cover and cheap flat nylon sails. You won't find many used because they don't last long. A good one with a lot of volume is your only chance at a cartop boat that might take two adults. Larger boats are too heavy to cartop and smaller ones don't have the capacity to float two adults on a regular basis.

Even for larger boats, most factories have left it to the backyard builders to have certain features. One popular feature would be really shoal draft in a sailing boat. Factory builders think 3' draft in a 20' boat is shallow but it is possible to get it down to 3" or so. And rigging a larger sail boat solo is something that the factories aren't interested in. It takes a special boat that you need to make yourself.

On the powerboat side, small cuddy cruisers with small outboard power, like your dad or granddad might have used in the 50's, are something you can build but not buy from a factory.

YOU WILL LEARN A THING OR TWO...

If there is anything certain about building a boat it is that you will learn a lot. I will warn that it is probably important to start small with your first boat. The techniques and materials can be very similar to those of a big project but you are much more likely to finish the thing because you can accept the thought of it with one gulp. Very large projects, even for experienced builders, must be thought of as a series of building events, one step at a time.

You will learn about materials. If fact even if you were building for a living you would always have to learn new materials simply because the suppliers are always changing things for their own reasons. Today's plywood is different from that of a decade ago, or a month ago in some cases. Glues and especially paints change all the time with no warning.

You will learn about tools. Today's tools are different from those of old days, some are better and some are worse. I don't own any special boatbuilding tools and don't design boats that need special tools. But if you are making an old traditional design you may be challanged by today's tool selection because in the old days they used many special planes, many times they were custom made.

You will learn about techniques. Again today's techniques are different from those of the past. Are they better than those of the old days? Probably not but they are better suited to todays materials. (Don't kid yourself into thinking that the old ways of building boats are obsolete. The old builders could build to any shape. The difference is, I think, that the old techniques need a lot of practice and tools and quality of lumber that we can't get easily any more.)

And once you get it done you can learn to make oars or sails or how to rebuild an old outboard motor. Then you learn how to use it all. You'll learn about water and weather and everything around it.

HAVE FUN!

I have found that all the intellectual arguments for building a boat at home are really for naught since most builders have already decided to build, an emotional decision. Nothing wrong with that!

I can assure you that most home boat builders will find the work is not work at all but is more like therapy. Most of us spend our day doing uncreative work that requires little thought. We seldom have any way to demonstrate what we can really do. And there is almost no chance of getting credit for our abilities. That is where a hobby like building boats can be so successful. Off you go banging and butchering the wood and getting full credit for it, good or bad. Want to make some changes to the design, something you could never do at work? Go ahead! Keep the basics in mind and you may come out with a better boat. You might contact the designer first to see if you haven't missed anything important. Does that sound strange coming from a designer? Before I started drawing my own boats, I built several Phil Bolger boats. I tinkered with them endlessly and made lots of changes. Most of the changes didn't really "improve" anything but I learned a lot in the trials and errors. And now I find builders tinkering with my designs. I try to keep an eye on how things turn out because most of the builders are quite smart and I'm always looking for a good new idea to copy. But you know what? Even when a change is a failure, we can usually straighten things out and I'm certain the end result was that someone learned an awlful lot about boats, more than he would have learned had he done the job per the plans. That, of course, is one of the huge benefits of building a boat as opposed to buying one - before it is all done you will be forced to learn a lot.

Boat building can get addictive. Your brain and hands both get a workout. With luck you produce something useful and maybe even beautiful.

NEXT TIME...

We'll review the very important issue of Sail Area Math.

TOOTS

TOOTS, ROW SKIFF, 10' X 4', 70 POUNDS EMPTY

Toots is a 10' flat iron rowing skiff, about half way between serious skiffs like my QT and the typical pram. Toots will have the capacity to carry two normal size adults because it has enough rocker to float 450 pounds with its ends still well clear of the water. The prototype was built by Barry Targan of Greenwich, NY. As you can see in his solo photo, there is a lot of capacity left.

Barry carries his Toots in the back of his truck but this boat may be one of the easiest to cartop. Sometimes a longer boat will actually load to the roof better than a shorter one, depending on the size and shape of the car. But unlike a longer boat Toots should get by with no ties to the bumpers, something to keep in mind now that cars have molded plastic bumpers with nothing to tie to. For that matter, most new cars don't have roof gutters to take a serious roof rack but the bike stores seem to have roof racks that clamp to thin air.

I drew Toots as a taped seam boat although it could easily be done with conventional nail and glue chine logs as Barry did. I'm pretty certain that the taped seams have advantages beyond the obvious ones of fewer lumps and bumps and lighter weight. A proper taped seam has all the seams and gaps filled and closed to the moisture that usually makes a nailed chine joint the first place to rot. Then again, Toots would be a good project to do with children and using the conventional wooden chine log would avoid the specter of kids brewing up pots of epoxy.

Toots needs only two sheets of 1/4" plywood. No jigs or lofting required.

Plans for Toots are $20.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

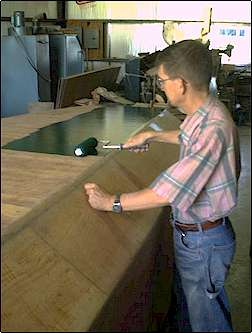

Caprice: Chuck Leinweber of Duckworks Magazine has finished the prototype Caprice. Here is a photo. Waiting for some shakedown cruises and a report.

Skat: I'm told the prototype Skat project is underway again and very close to being done.

Normsboat: This is an 18' sharpie being built by Cullison Smallcraft in Maryland. You should be able to check on it by clicking through to his web site at Cullison SmallCraft (archived copy, actual site no longer active). He is presenting an excellent photo essay of how to assemble a flattie.

Vamp: I received word that a prototype of the little rowboat Vamp is completed up in Utah. Hopefully photos and test report soon.

Family Skiff: A Family Skiff has been started in Virginia.

AN INDEX OF PAST ISSUES

Herb builds AF3 (archived copy)

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)