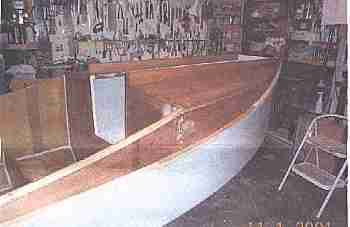

Last year's Rend Lake Messabout.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1apr02) This issue will present results of boiling glued wooden joints. The 15apr02 issue will discuss taped seams.

ON LINE CATALOG OF MY PLANS...

... can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you. The prices there are $6 more than ordering directly from me by mail in order to pay Duckworks and credit charges. The on line catalog has more plans offered, about 65, than what I can put in my paper catalog and the descriptions can be more complete and can have color photos.

Duckworks Magazine also now sells real 4 ounce white Dacron sailcloth for $7 a yard. (It's a fact that I probably would not have pursued polytarp sail construction if I could have gotten real sailcloth at that price.)

THE LAKE CONROE (HOUSTON, TEXAS) MESSABOUT will take place on April 13. For more information go to Shortypen's boat page

|

Left:

Last year's Rend Lake Messabout.

|

|

|

I BOIL WOOD

Blame it all on the late Pete Culler. He was talking about making boats and boating things with Weldwood glue, which is a powdered glue that you mix with water. Very easy to use but the manufacturer says it is water resistant, not waterproof. The usual way to test glue quickly for waterproof is to boil it for an hour. Culler said something like "If you're going to boil your boat, don't use Weldwood" and was widely quoted thusly, including by Harold Payson who has done more to educate us about plywood boats than anyone.

So I made several boats using Weldwood and still have several around and don't worry about it. But one of them, a Bolger Jinni that was my second homemade boat, had to sit outside for several years and it often filled somewhat with rainwater in storage. After a few years of this treatment I noticed the internal chine logs were getting spongy where they were constantly wet and little leaved plants were growing out of them at times. One year I chopped out the bad parts and noticed there was no sign of any glue in those joints, they were held only by nails and the external fiberglass tapes. I gave it little thought thinking that I didn't get enough glue in the joints during assembly. I repaired the chines with fiberglass/epoxy taped seams and made a cover for the boat and improved the drainage. But a year or two later the mainmast, which was laminated from two pieces of wood, came apart at the base where it stuck out from under the cover. The Weldwood there was also gone.

And I came to the conclusion that Weldwood, indeed, was not totally waterproof. And the boil test was perhaps not a lot of hooey after all!

PLYWOOD...

Plywood glue has always caused worries and since it varies so much from load to load I began to advise that builders boil a piece if they were at all suspicious. I got a letter from one builder who had boiled some "good buy" plywood and it delaminated after 20 minutes in the boil pot. Was that good enough?

I didn't really know since I had never boiled anything!

So I rounded up some different plywoods that I had out in the shop, all of which were supposed to have "exterior" glue. I put them in a pot and, when my wife was away, boiled them on the stove.

My first sample was a piece of cheap 3/8" BC pine. After an hour in the boil it showed no sign of delamination.

My second sample was a piece of 3/8" (actually slightly less) exterior plywood that I had used for the bottom of my AF4 which I built four years ago. This had two thick crude looking plies of fir (I think) with a thin skin facing of a flawless mystery wood. After an hour in the boil it showed no sign of delamination.

My third sample was a piece of cheap 1/4" lauan underlayment which was sold at a real lumberyard, not a depot type of store. The sheet was unmarked but the yard said it had waterproof glue. After an hour in the boil it showed no sign of delamination.

So the builder's plywood that was delaminating after 20 minutes in the boil was clearly not the same stuff I had.

And now more than ever I think the boil test is a good quick way of checking glue.

GLUED JOINTS IN LUMBER...

With the plywood testing done I thought to test in the same way some glues that have been used in cheap boatbuilding. Here are my results.

Weldwood. A few years back I cut a small section off the edge of my Birdwatcher's centerboard and I tested that piece. The board is laminated from layers of 1/4" plywood using Weldwood water mix glue. After an hour in the boil pot it was still quite together which is interesting since this is the glue that caused all the furor in the first place. I was able to pry it apart with a knife but I'm still not sure what that means.

Tightbond2, it says "not for use below waterline" right on the bottle. Guess what? After an hour in the boil it held up as well as any glue tried.

PL Premium is a construction glue that you use in a caulking gun. Very handy and thick so exact fits or lots of pressure aren't needed. I had a piece of an old project, about 3 years old, that had a 2x2 glued to 3/8" plywood with this glue and it had been outside the entire time with no sign of failure. After an hour in the boil pot it looked quite solid but when I gave the glue line a pry with a knife it popped apart cleanly where the glue met the wood. Strictly speaking I suppose that is a failure. But here is another test result from a recent email I got:

" First, I am using PL premium for the glue. I tested the strength by gluing up two small 2 X2's, letting it dry and I soaked it in water for a week(submerged). I then took a 5 lb sledge and commenced on beating it soundly. It held. I was impressed. I did the same with a liquid nails product and it broke apart with handstrength."

Epoxy, in this case a bit of "DC7" which is an epoxy paste in a little can from the hardware store. I've used it with total success to stop rust holes in old fuel tanks. After an hour in the boil it held well but clearly was getting very soft, as did the PL Premium. Epoxy is well know to have strength problems at higher temperatures.

WHAT IT ALL MEANS..

Like Pete Culler I think all the glue are sufficient for a boat that is stored under cover. As for the long term effect of water on the glues, I'm not sure the test proves anything. The idea of " I soaked it for a few weeks" may not be good enough for a boat that will sit in the water (or fill with rainwater) for months at a time.

I would not use any plywood that didn't pass the one hour boil test. After all, the pieces I used passed and they were from very cheap sheets. And just because the plywood passes the boil test, it may delaminate in places where not enough glue was used. The lauan I tested was like that - bubbles and peels at edges where there isn't enough glue.

A Final Thought..... I saw this posted by Dave Carnell on news:rec.boats.building

"....the real advantageof interior glue is that it is a cold press operation vs. the hot press operation required for exterior glues.

The durability of the interior glues is surprising in some ways. I once tested lauan underlayment by soaking in water until it sank, drying at 150°F. in an oven, resoaking, and redrying. It didn't delaminate. I also tried freezing it while wet and it held together. When I bent it for boat planking on a hull being built outdoors, it came apart as soon as it got rained on. Once it is stressed, the whole game changes.

I have seen people talk about testing in a dishwasher, but that isn't good enough. Boil it for an hour or two. If it doesn't hold together, it is no good."

NEXT TIME...

I'll show how I do taped seams.

PICARA

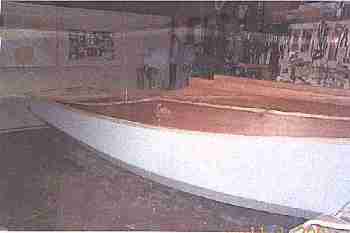

PICARA, CABIN SAILBOAT, 18' X 7", 1300 POUNDS EMPTY

A while back I presented a design called Fatcat2 which was a 15' x 6' unballasted sailing cuddy catboat. It is still in the prototype catalog, although one was built a few years ago but never used to my knowledge. A problem with any unballasted boat is that if it capsizes it will usually lie on its side and the skipper will need to go for a swim to right the boat and then he has the problem of getting back into the righted boat.

The usual fix for that problem is to deck the boat over very well so that nothing will flood when the boat gets knocked down by the wind. (I'm reminded of Reed Smith's Rule that any boat that gets sailed a lot will eventually get knocked down.) Then ballast is added down low such that the boat's center of gravity will be "below" the boat's center of buoyancy when it is on its side. The lower the ballast, as on the end of a deep fin or keel, the less ballast is needed but of course the draft of the boat goes way up. Buoyancy up high, such as a high raised deck, also helps but there are limits to that too since the boat's CG will also be raised with it, both because of more structure up high and also because the crew weight, which often is a major contributor to a high CG, must be lifted higher so that the skipper can still see ahead over the new raised deck.

So Picara is in a lot of ways a Fatcat2 that has gone through the above changes to make it self righting, that is to say if knocked over it will right itself when the wind force is eased, with the crew staying on the deck, shedding water like a duck and being ready to go again once the crew feels up to it. (Even here the idea of "self righting" means different things to different sailors. Howard Chapelle wrote somewhere that a sharpie is selfrighting if it can return from 45 degrees of heel. I'm quite certain that is not enough for most of us. Blue water sailors try to self right from 140 degrees of heel. No, the wind won't blow you over that far but a big wave can roll you that far. On my ballasted boats, like Picara, I try to get the boat to self right from 90 degrees, a compromise I suppose, but I don't design blue water boats.)

To get Picara to right from 90 degrees with two adults sitting on the aft deck requires 500 pounds of steel ballast spread flat on the deepest part of the boat's bottom in addition to using a 1" thick plywood bottom which also has about 100 pounds of ballast effect. Sound like a lot? Maybe so but the numbers kept coming up the same using Hullforms6 to figure the hydro work. I believe it. I tried it with water ballast but gave up. Steel is over eight times as dense as water so the 1-1/2" steel plate I show as ballast would be equal to a water tank over 12" deep to match the weight, but with internal ballast the water would end up centered about 6" above the bottom where the steel sits centered .75" above the bottom so the water ballast was no where near as effective here as steel. It won't work here.

Picara is 18' long where Fatcat2 was 15' in order to get a cabin that two people might really sleep in. There is a small anchor well ahead of the cabin, a raised deck aft of it, and a motor well in the stern. I used multichines to get a hull that can handle rough water better than a flattie. That makes it a taped seam project. She needs nine sheets of 1/4" plywood, six sheets of 3/8" plywood, and seven sheets of 1/2" plywood. The resulting pile of plywood would weigh about 800 pounds and I would expect the empty hull to weigh about that. Add 500 pounds of ballast and you have about 1300 pounds on the trailer. The wide deep hull can handle that and it takes a total weight of 2500 pounds to set it down 10" deep so its chines touch the water.

As for the sail rig, I used a gaff sail to get good area from a short 17' mast which pivots on a tabernacle and stows within the length of the trailered boat. I added a small mizzen for balance and provide steadying at anchor or during sail changes.

Prototype Picara plans are $30.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Here are the prototypes abuilding that I know of:

Electron: The California Electron is coming along. Right now a four cycle 2 hp outboard has been purchased so the original electric idea may wait a while.

Mayfly: The prototype of the original 14' Mayfly is finished in New York state. Here it is on its first sail (Long Island Sound).

A Campjon is ready for paint in exotic Queensland, Australia. Another is underway in New York with an enlarged cuddy.

AN INDEX OF PAST ISSUES

Herb builds AF3 (archived copy)

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)