Garth Battista of Breakaway Books is a publisher of sporting books and addicted to building boats. Here is a Larsboat he completed last year.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1mar03) In this issue we'll figure how big your boat needs to be to float all that weight you figured in the last issue. Next issue will present a homemade gadget to measure propellor pitch.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

... can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Garth Battista of Breakaway Books is a publisher of sporting books and addicted to building boats. Here is a Larsboat he completed last year.

|

|

|

FIGURING DISPLACEMENT

THE VERY BASICS...One of the real basic errors in boat design is to not match the capacity of the hull to the weight it needs to carry. It's actually pretty easily done. Let's take an example: a fellow wants a 12' skiff to handle two adults. He figures the empty boat will weigh 120 pounds and the adults together at 350 pounds. So he has to float a total weight of 470 pounds.

One thing is for sure: no matter what the shape of the hull, it will sink into the water until it pushes aside, or displaces, 470 pounds of water. (They way I heard it was that ancient Greek mathematician Archimedes figured out the basics while sitting in the bath tub.) Fresh water weighs about 62 pounds per cubic foot and salt water usually about 65 pounds per cubic foot. So the volume of fresh water displaced by the 470 pound boat is 470/62 = 7.6 cubic feet. That was easy!

Next the problem becomes one of shaping the underwater part of the hull such that it displaces 7.6 cubic feet with good flow lines.

METHOD 1: THE PRISMATIC COEFFICIENT...

We talked about the prismatic coefficent way back in the 15mar99 issue which you can always view by clicking on the "way back issues" link at the bottom of this website. Remember that we construct a prism with parallel sides the same length as the waterline length, like this:

And the same cross section as that of the boat's maximum beam, like this:

The hull will fit neatly into the prism. You could figure the volume of that prism simply by multiplying the length by the cross sectional area. Divide the volume of the actual underwater hull by the volume of that prism and you have the prismatic coefficient. But, you say, in the early stages of the design you don't know the underwater shape well enough to figure the volume of the actual hull. We are still at the guessing stage. What to do?

We're in luck! What is interesting to me is that the prismatic coefficient doesn't vary much from one displacement hull to another, as far as normal small boats are concerned. Jewelbox, with a flat bottom and squared off ends, has a prismatic coefficient of about .60

And Toto, with very pointy ends and multichine cross section, has a prismatic coefficient of about .50

So I figure if you were to assume a halfway normal displacement hull has a prismatic coefficient of .55 then you would always be within 10% which is actually pretty good.

So without drawing a line I might say that the 470 pound weight will need a "prism" with a volume of 7.6/.55 = 13.8 cubic feet. The prism could have any combination of cross section and length that will have that 13.8 cubic feet total volume.

Remember that the prism has the same length as the hull's waterline length and cross section as the boat's maximum cross section. Remember we want a 12' boat, but the waterline will be shorter if we want some rake to the ends (for looks) and maybe enough rocker to make sure the stem and stern don't drag the water (for low drag). We might guess that the waterline length will really be about 10'. Then the maximum cross section would have to have 13.8/10 = 1.38 square feet of area below the waterline. If we wanted a flat bottom 3' wide (wide enough to have sailing stability and narrow enough for reasonable rowing) we would have a draft of approximately 1.38/3 = .46' or 5.5".

If we wanted a different cross section than the simple box shape I'm assuming here, we would have to tinker a bit. Draw up a cross section with the 1.38 square foot cross section and see if we like it. Actually in this case I'm going to flare the sides out to 4' at the top of the wale at the cross section. But that won't affect the area under the waterline much. We might sketch out something like this:

METHOD 2: THE CURVE OF AREAS...

This method of the "curve of areas" is an accurate and flexible way of determining the volume of almost any oddly shaped thing. It's actually pretty easy to do but first you need a drawing of the proposed boat (unlike the prismatic coefficient which just needs a general idea of the boat).

Let's take our proposed boat and draw a line on it that represents 5.5" draft, our guess at what is needed to float 470 pounds. Every now and then along the length of the hull we take cross sectional cuts of the hull and measure the area at each cut below the 5.5" waterline. The cuts can be taken anywhere but there must be enough to get a good definition fo the hull. Actually for a normal boat about five cuts will do. The more you take the more accurate your work but five will get you really close. Our example boat might be like this:

The dimensions of the underwater sections are measured right off the paper drawings and the area of each is calculated like this:

Next we graph those underwater areas spacing them the same distance apart as they are on the real hull to get the "curve of area" like this:

The area enclosed under the curve of areas is a volume and is indeed the volume of the underwater hull - it's what we are looking for. In the old days you would measure the areas with a planimeter, a clever and expensive gadget. But you can do well by just breaking down the curve into triangles and trapezoids, figuring the area in each trapezoid, and adding them all up. In the example, second trapezoid from the left is figured by 1/2(175+209)X12 = 2304. Adding the sections together gives us a total of 12500 at 5.5" draft. That equates to 450 pounds of water. So the first guess was off by 20 pounds or about 4%. By the way, the drawing showed a waterline length of 9'5" instead of the first guess 10'.

As mentioned before this method can be used to figure the volume of almost anything. Let's say we wanted to find the weight of a mast. Say the mast is 24' long, 3.5" in diameter at the base and 1.5" in diameter at the top, with a curved taper between. The figuring of the volume might look like this:

1920 cubic inches equals 1.1 cubic feet. Wood usually weighs 25 to 35 pounds per cubic foot. At 30 pounds per cubic foot the mast would weigh 33 pounds.

You can also use the area of curves to find the CG of the object, too. For real simplicity I've seen designers in the aircraft industry draw the curve on cardboard, cut it out and balance the thing on a knife edge. The item's CG will lie on that balance line.

THE COMPUTER METHOD...

Finally you can use your computer to figure it all out. I'm sure all of you know that getting the computer to spit out the right answer might take a lot longer than doing it by hand. The program I used to get the drawings above was Hullform6s which can be downloaded from the links shown at the end of this page. What were the answers that Hullform6s predicts for the 12' skiff with 470 pounds displacement? 5.5 " draft, waterline length of 9'4", and prismatic coefficient of .55! So the first guesses were quite good. But the area of curves method was also excellent, within 4%. It showed the same waterline as Hullforms. Perhaps with more data points to flesh out the curve the hand method would get the same answer as hullforms but I wouldn't bother. You will never guess the weight of the finished boat within 4%.

NEXT TIME: I present a simple gadget to measure the pitch of your propellor.

Seal Cove Skiff

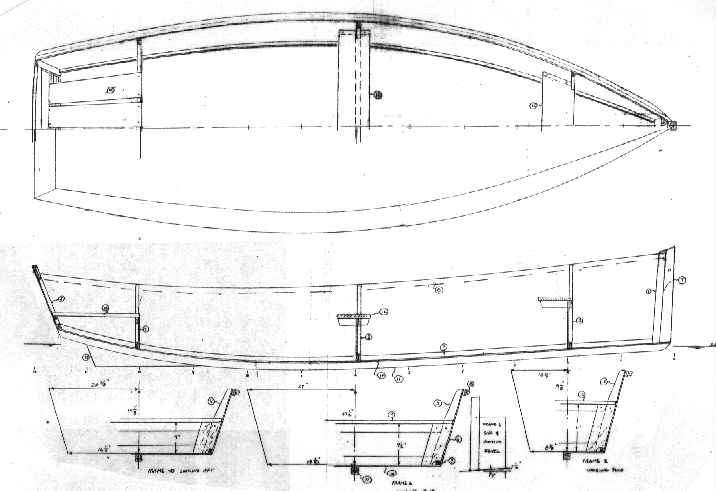

SEAL COVE SKIFF, ROWING SKIFF, 12' X 4', 100 POUNDS EMPTY

This boat is an "instant" version of the "8-Foot Seal Cove Skiff" shown on Plate 34 in Howard Chapelle's classic book BOATBUILDING. Such a great book, although it predates the building methods that this modern version uses. I recommend that you get the book if you can. If you turn to Plate 34 you might notice that the "8-Foot" skiff is really 12' long! Sometimes there is an explanation for a discrepancy like that such as with traditional dories that are listed by their length on the bottom and not by overall length, but in this case I'll bet it is a goof. Next you will see that Chapelle's skiff had a slanted internal transom towards the bow so there is an open well with a wheelbarrow wheel up there, and then wheelbarrow handles on the stern! So the boat is self trailering, sort of. Finally Chapelle shows a small downwind-only sailing rig. I did not want to copy those features but you might get the book and try them.

The shape of these hulls is totally tradional and effective. The sides have constant flare almost the entire length except at the bow. There we find a great twist to the planks to get a stem that is nearly vertical. Flare is nearly always good in a rowing boat because it gives both the narrow bottom that benefits speed and the wide top that gives good spread for the row locks plus extra room and stability. The vertical stem gives more waterline length which implies more speed. The bottom treatment has the stem always just out of the water to encourage the boat to go over the water instead of plowing through it. Then the bottom runs straight back and down to a point just past the midsection and then it turns quickly up to well above the the normal waterline. The idea is to load a boat like this with extra weight in the stern to keep the stem just clear of the water. The result is a lot of capacity. Seal Cove can easily take two full sized men which is unusual for a 12' rowing skiff.

The hull is made with three sheets of 1/4" plywood instead of the 5/8" cedar boards and heavy oak framing of the original. I kept the internal chine logs of the original design and I think this is the only boat I've ever drawn that has them. But if I were to build one of these for myself I would probably use taped seams or maybe external chine logs instead.

Plans for Seal Cove Skiff are $15 until one is built and tested when ordered directly from me. You can also buy them online at www.duckworksmagazine.com.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Here are the prototypes abuilding that I know of:

The Australian Twang builder is done and is testing, searching for the ideal seating position.

The Oracle builder in St. Louis is done, waiting for a foot of lake ice to melt.

The Alabama Skat is getting its seams taped.

A Piragua18 is being completed in Georgia:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)