My AF4 awaits a perfect testing day.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1May03) In this issue we will measure propellor "slip". The 15May issue will rerun the article about taping seams.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

... can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

THE 14TH ANNUAL MIDWEST HOMEBUILT BOAT MESSABOUT will take place at Rend Lake in Southern Illinois on the weekend of June 7 and 8. Lots of folks come on Friday and leave early Sunday. Take I-57 to exit 77W and then follow the signs to the Gun Creek Recreation Area. Camping at this Corps of Engineers facility is $10/night and that includes the ramp fee. There is no schedule of events except a pot luck dinner in the campground on Saturday evening- we wing it. This year some of us have reserved the campsites on the water of the two middle camping loops so look for us there if we aren't at the boat ramp.

|

Left:

My AF4 awaits a perfect testing day.

|

|

|

PROPELLOR SLIP

(Jeeze! I noticed lately that the rest of the world is using "propellErs" while I am using "propellOrs!" I looked in my dictionary and saw that the chancellOr lives in the chancellEry. Luckily that dictionary gives me a break by saying a propellOr is the same thing as a propellEr. Thus we all call it a "prop". I'm reminded that logic is taught by math teachers and not English teachers. And also that I once took a technical writing class where the professOr said that spelling isn't as important as your old teachers told you. He said meaning is never lost by misspelled words but that humor is often added. Or is that humour?)

In the 15March issue I showed a simple gadget that I use to measure the "pitch" of small propellors. Recall that the pitch is the amount a propellor will move forward with each revolution just as a screw has a pitch. In the US the pitch is stated in inches. Thus a prop with a 10" pitch will screw itself forward 10" assuming it does not "slip".

But props do slip for several reasons. First, the pitch has nothing to do with the actual size and area of the blades. So in a case of a powerful boat with tiny props (but of the right pitch) they might indeed spin around in place and do nothing because they are overloaded, sort of like a dragster spinning its tires into smoke. There are ways to calculate the blade area needed to prevent it but this is not a problem with the size of boat I design.

Another cause of pure slip is a damaged blade. This happened to me a few years ago with a Sears7.5 (an aircooled Eska) on AF4. While motoring around I felt the motor touch bottom. After clearing the sand bar the motor revved to high heaven and the boat went nowhere. Below about 5mph it would bite and push the boat but above that it was all noise and no thrust. I was sure the shear pin was gone but on checking found it intact. I worried the boat back to the ramp and decided to put the motor aside until I could check out its clutch, an internal job I wasn't too interested in. Eventually I noticed the leading edges of the blades had burrs. I sanded them off in a couple of minutes and, guess what? It was like new! Once again I got speed consistant with the noise that engine makes.

Perhaps the major element of slip is that on a boat with a lot of drag the prop is moving the water aft more than moving the boat forward. Obviously, if you tied your boat to the dock and fired up the motor you would measure 100% slip even though the motor/prop were functioning totally correct.

And a prop needs a certain "angle of attack" to the water to produce thrust in the first place and that would measure out as a part of total slip. I don't know what that angle is but an indication might be that it is very hard to get slip down below 10% in any case. On a 10" prop, typical of a small outboard that will peak at maybe 20mph, that would be 1" of pitch. I suppose midway out on the typical prop blade that would amount to 2 or 3 degrees of "angle of attack".

MEASURING SLIP

To measure prop slip you need to compare the actual speed of the boat by the theoretical "no slip" forward speed of the prop.

In my tests the speed of the boat was measured with a gps. (All tests were with my AF4 at about 800 pounds total weight.)

The "no slip" speed of the prop, which I will call Vns, takes some calculating. You start by knowing the rev's of the powerhead.

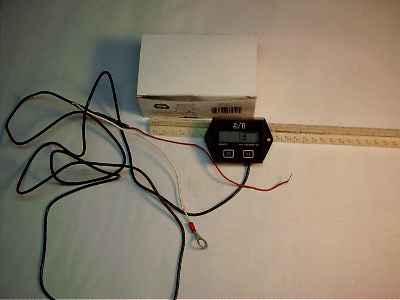

In my tests the rev's of the powerhead were measured with this handy tachometer on loan from Motor Max. It is a handy thing bought for about $40 from www.northerntool.com. One lead goes to a ground on the motor and the other wire wraps around a sparkplug wire. You can set the thing for different ignition designs, for example a spark on each rev, or every other rev, etc. The only problem I had with it is that the lead is so sensative that on a two cylinder motor it can pick up the jolt from the wire several inches away and give a false reading. What I did on a two cylinder engine was to wrap the lead around both sparkplug wires, right where they come out of the ignition plate and are close together and set the gadget to read two jolts per rev. Then all was fine. The gadget also records the operating time of the motor, thus you see the number on the screen below. When the motor is running it reads revs, when the motor is not running it shows total operating time.

If you know the revs of the powerhead you can figure the revs of the prop by knowing the gear ratio of the lower unit. You can guess that ratio by turning the powerhead one turn and noting how much the prop turns, getting all the system's slack out first (it can be considerable). By doing that and by doing some research on the acutal gears we found that the small Clinton type lower units (also used by Eska, etc.) had a .66 gear ratio and that the OMC lower units that I have were all .57. So if the powerhead measured at 3000 rpm then the Clinton prop would be turning 2000 rpm and the OMC prop would be turning 1710 rpm.

Now you can do some calculating. Powerhead rev's times the lower unit gear ratio gives prop rev's. Prop rev's times the prop pitch gives the "no slip speed" Vns in inches per minute. Inches per minute divided by 1056 gives speed in statute miles per hour. It turns out that for the Clinton lower unit, the Vns (in mph) will be the pitch (in inches) times the powerhead rpm all divided by 1600. For the OMC lower units the Vns (in mph) will be the pitch (in inches) times the powerhead rpm all divided by 1850.

ACTUAL TESTING...

The actual tests with AF4 were quite simple. Just mount a motor, remove the cowling so that the tach could be wired up in a minute, head out on the lake and run at several speeds, writing down the rpm at each speed. Then chart that data along with the Vns for that prop and lower unit. Here is the first one with my lowly SeaKing3.5, which is a Clinton made motor from about 1970:

Slip measures out at about 45% across the entire range. I've read that is very typical of low hp/weight boats with small props that won't plane. I got similar results but up to 50% slip with a Sears5 (Eska) using a 6" pitch that gives 6.8mph at 3500rpm full throttle.

Next I ran a 12hp Goodyear (OMC, about 1956) with a 10" semiweedless prop that was standard on motors like this for a long time.

Now we have something different with slip starting at low speed with about 30% maxing out at 35% when the boat is at its "hump" before planing. Once it starts to plane the slip reduces, going down to about 23% at full throttle at 3670 rpm at 15.1mph. The motor is rated at 4000 rpm indicating that a lower pitch prop might be in order.

Next I tried a Johnson10. This one has a 7" prop that is not weedless. It has large straight blades. It was a very windy day but I found a sheltered cove for most of the testing.

The slip of this prop is much lower than that of the weedless prop. It slips about 25% at low speeds, dropping to about 10% at full throttle of about 14mph. At one point it went 15 mph at 4300 rpm for 6% slip, probably wind aided. This motor is also rated at 4000 rpm. I don't know if that should be considered to be a "redline". But in fact I used this motor for a few years when my AF4 was still stripped down and lighter and a lot faster than it is now. We once measured it at 17mph with this motor and that would mean about 5000+ rpm. That seemed to do no harm. The motor is 47 years old!

A BOX OF PROPS...

Motor Max brought over a box of props for the OMC's for one more round of testing, this time with a SeaKing15, which is an OMC motor from the early 60's.

Funny thing about those props. They were from several makers and sizes but on my pitch gadget they all measured 1" less in pitch than the prop markings indicate! I'm pretty sure my gadget measures pitch on the blade's aft face correctly. Max also brought along a copy of Dave Gerr's PROPELLER HANDBOOK. He states that measuring pitch is not all that easy , and he presents a gadget similar to mine with a triangle template to meaure the angle of the aft face. Here is how I account for the difference. All these props have cambered blades, that is to say they have a curved airfoil shape. So even if they were mounted flat (as I would measure it) they would still produce some forward thrust when spun. So I figure the prop makers allow for that by adding a "one inch for the pot" sort of thing. (I notice that prop makers have very elaborate guages for measuring pitch and don't just measure it across the aft face. They can measure it in several places across the blade and might say that my 10" pitch prop actually has 8" pitch on the leading edge, 10" pitch in the center and maybe 12" pitch on the trailing edge.)

Anyway, off to the lake with the SK15 using a 10" standard prop. Here are the test results:

More or less similar to the Goodyear12 results except now slip continues to drop with speed to 15% at 3800rpm full throttle at 17.3 mph. This motor is rated at 4500 rpm indicating that less pitch might be nice. We tried it with several other props but settled on this 9" standard as being the best of the bunch:

Now full throttle gave 18.5 mph at 4300 rpm with 10% slip. That is not a huge increase from the 17mph that the 10" prop gave even though the revs are higher and the slip is less. The thing about changing prop pitch is that if you increase pitch you increase the load on the engine and you lose revs, so the top speed may not change much. And if you decrease pitch you decrease the load on the engine and you gain revs, but again the top speed may not change much. It is horsepower that moves the boat and horsepower is torque times rev's. Depending on the torque/rpm curve for a particular engine you might find that the horsepower is fairly constant over a pretty wide range because the torqe falls off as the motor revs up. And if your motor has say a constant 15 hp between say 4000 and 4500 rpm then the top speed of the boat might be constant too anywhere in that range. I'm thinking that is about true with my Seaking15 and most of the OMC's and that the extra speed I got was due more to a more efficient prop than to raising rev's and tapping into more horsepower.

NEXT TIME: We'll rerun the taped seam essay..

TWANG

TWANG, POWER SKIFF, 13' X 4' X 100 POUNDS

Twang is a light small power skiff, light enough to cartop (I notice the wheels on the transom in the photo) if you keep your mind on weight as you build and if you can figure out a way to carry your motor and fuel without ruining your car. It would also be well suited to someone who wants to carry his boat in the back of a pickup truck. Luke Spreadborough built this prototype down in Queensland. (Looks like big registration numbers are all the rage in Australia.)

I've never seen a hull shaped like this before although I'm sure it has been done. Look closely at the lines and see that the bottom is straight for the last 10', and that she is totally flat bottomed for the last 7'. That gives the small boat better capacity and I'm thinking the ability to plane with a small motor, say with 5hp with a light skipper. That is about like my little jonboat design, Jon Jr. But this bow is pointed and designed to meet a wave with a deep V shape and hopefully be softer riding than the totally flat bottomed jonboat or flatiron skiff. There is bound to be turbulence where the deep V meets the flat bottom but I'm hoping it won't be a factor on plane since only the aft half of the hull will be in the water then. Here is a photo of Luke's bow when it was still in the "wired" stage prior to having its seams taped:

Luke ran the boat with several motors. Here it is with a 2.5hp (I think). Don't stand up in a boat like this in real life (I think gravity works the other way in Australia and you can't fall "down").

Luke also tried Twang with a 5hp (I think) sitting forward and this looks to me like the way to go:

And he tried it with a 7.5 (I think) and it went like this.

In my opinion these little power boats aren't safe with big motors. I'm suggesting no more than 5hp. And Twang would max out with two adults. Another factor with small boats is that by nature they aren't as seaworthy as larger boats. So I'm still not sure if the V bow in Twang is a success. But you would think it has got to be better in rough water than a flat bow. For some boaters who don't want big power or don't often take folks along with them Twang might fill the bill.

Twang is made from four sheets of 1/4' plywood with taped seams.

Plans for Twang are $25 when ordered direct from me.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Here are the prototypes abuilding that I know of:

The Alabama Skat now looks very boatlike:

A Piragua18 is being completed in Georgia. (This boat is done and tested but I'm hoping for a good "in the water" photo.)

This dog contemplates its new house. Oh Canada!

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)