Barry Johnson and company with a new Jonsboat.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1Sep03) This issue will give thoughts about measuring propeller thrust. The 15Sep02 issue will present a rot repair not approved by Woodenboat.

The 12th ANNUAL INDIANA MESSABOUT will take place at Lake Monroe (just south of Bloomington) on September 19 thru the 21st. All at the Paynetown Recreation Area. For more info contact Bob Bringle at rbringle@iupui.edu.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Barry Johnson and company with a new Jonsboat.

|

|

|

Measuring Prop Thrust

"THE MOST SIGNIFICANT NEGATIVE EXPERIMENT IN THE HISTORY OF SCIENCE"!!!

Before I get started talking about propeller thrust I want to set the stage with a dedication to Albert Michelson who spent his life measuring the speed of light. Born in Poland, his family came to the US when he was a little boy. He became expert with optics. In the mid 1800's the speed of light was known in a general way and Michelson, along with his helper Morely, made a device that would measure the speed of light to a degree of accuracy never known before. In fact they thought it so fine as to measure the effect of the earth's orbital movement on the speed of light according to the "ether" theory of light propogation that was current at that time. So they measured and measured and measured. They did indeed zero in on the speed of light but saw no orbit effects. The speed of light was the same no matter how it was measured. Michelson had enough confidence in himself that he published the results even though there was no explanation to be had. That was in 1883. Then in 1905 along comes young Albert Einstein who knows about Michelson's results. Einstein doesn't really explain it except maybe to say "accept it because that is the way it has been proven. The speed of light is always the same no matter how you measure it." And with that basis Einstein went on to figure his theory of relativitly and the rest is history. So just because you can't explain something you measured doesn't mean it is wrong.

NEXT...

Some of you may recall that I've noted on several occasions the virtues of the program Hullforms. You can link to the Hullforms website in the links at the bottom of my page and download a free trial version. In one of the later trials there is an option that will figure (somehow) a drag vs speed chart for your hull given a certain weight and trim. I don't know how it is figured. In fact I'm not too sure the Hullforms writer took the results all that seriously since he presents several curves using the equations of several professors, and since he didn't put grid lines on his charts leaving you to think they are probably quite approximate. This is not an instantaneous program. You must "model" your boat first by plugging in the offsets that define its shape and you need to tell it the weight and center of gravity information. Anyway, here is a picture of my Hullforms AF4 model.

My real AF4 looks like this (back a few years ago when both the boat and I were younger and lighter)...

The Hullforms program predicts for this model, at a full weight of 800 pounds (about real life) and a cg location 11' aft of the stem, this drag vs speed chart (I've added grid lines to make guessing easier).

Well now, if such a chart is accurate can Hullforms be used to predict the performance of a boat given a certain weight and trim and power??

PROPELLOR THRUST....

... seems to be something that no one wants to talk about (except trolling motor guys who refuse to talk about horse power). All gas outboards are measured in horsepower. Sometimes someone will tie his boat to a tree and measure the static thrust of the motor, but is that an indication of thrust at speed? The thrust of an aircraft propeller is said to decrease with speed and the thrust of an aircraft jet increases greatly with speed so knowing the static thrust may not be much of a help in predicting thrust at speed.

You might recall in the "horsepower" essay from a few issues ago that horsepower is basically speed times a load. Hey! That chart above is speed times a drag so it can be used to figure the horsepower pushing the boat. Does it work? Let's take an example. It is known that in real life my 15 hp motor will push my AF4 at about 18mph tops. But when I look at the Hullforms chart I see that at 18 (about 15.6 knots) mph the hull will have about 120 pounds of drag. 18 mph is 1600 feet per minute so the speed times the load is 190,000 pounds - fpm. A horsepower is defined as 33,000 pounds - fpm so the chart predicts 5.8 horsepower needed to get 18 mph on the AF4! Not much agreement there.

SO I MAKE A THRUSTOMETER...

I tried to think of ways to measure the thrust at the prop as the boat was underway. If I were a true tinkerer's mechanic I think I would try something like this: the motor mounts on a transom bracket that is hinged at the top and has a "load cell" sort of thing on the bottom. I thought that might be a small hydraulic cylinder more or less like an auto's brake cylinder with a pipe that leads to a pressure dial on the dash. As the motor pushes forward at the prop the cylinder gets pinched against the transom which is resisted by the oil inside with increased pressure. Read the pressure in the cylinder with the gauge and you can figure out the total force on the cylinder and from there you can figure the thrust at the prop. This could be a permanent thing although I've never heard of it being done.

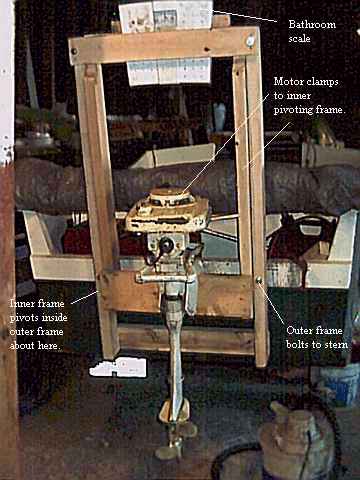

Not being a true tinkerer I settled on a method that relied on 2x4's, duct tape and a bathroom scale. Here is a photo of my Thrustometer.

The outer frame of the thing bolts to the real transom. The inner frame which has the motor mount is pivoted inside the outer frame. As the propeller thrusts forward the inner frame wants to swing its top aft. In doing so it pinches an ordinary bathroom scale which you can read very easily. The scale does not read the prop thrust as 1 to 1. Since the motor mount pivot is about 20" from the prop thrust line and the scale is about 33" above the pivot, the actual thrust at the prop is about 1.65 times the scale reading.

This bolts to the transom with two small bolts. I don't think it will take for very long the stresses of trailering so I mount it on the hull after the boat has been launched. Also the thrustometer is not braced in any way to take reverse thrust of the motor so that is a no no. I tried to keep the motor mount as close to the real transom as possible so that the motor geometry would be as close to the real use geometry as possible. I thought the limiting factor here would be the motor's clamping handles and I left just enough space for them. But in use I found I can't tilt the motor forward with the thrustometer so care is needed that way in addition to not being able to use reverse. Plan ahead.

DOES IT REALLY WORK?????

These bathroom scales are wonderful things and I must take one apart sometime to see what makes it tick. This one cost $3 at Dollar General. When I hang a motor on the Thrustometer it's weight alone puts pressure on the scale. No problem since the scale has a wheel to zero that out so all tests start with zero.

First testing was done with a 1956 Montgomery Wards 12, a Gale made motor that is essentially an OMC. I could tell the moment I popped it into fwd that the Thrustometer was OK. Testing actually only takes a few minutes using a gps. Starting from idle in fwd let the motor and boat settle to a certain throttle setting and write down the speed and scale reading. Increase throttle to a new speed and so forth right up to full throttle. Afterward figure the prop thrust using the 33/20 factor of the Thrustometer's geometry and that is the prop thrust, right?

In detail I don't think it really is the prop thrust because the drag of the lower unit never gets into the system. The lower unit drag I think cancels itself out and never gets measured. So the prop thrust is no doubt actually greater than what I am measuring. BUT THAT IS GOOD! I think what is really being measured here is the thrust actually pushing the boat forward. It is the force that counteracts the drag predicted by the Hullforms chart!

Also I think that in detail the Thrustometer seems to slow the boat down about 1mph. At least with the two engines I used I got that result both times. It could be the extra weight in the stern, something AF4 has never cared for. Also I noticed a lot of splashing going on back there that is not present usually. The Thrustometer mounts totally above the bottom of the hull so I don't really know what the splash is about.

Here is a photo of the Thrustometer in action with a Montgomery Ward's 15 mounted (another Gale OMC motor from about 1960).

I plotted the results of the two motor tests and got this:

Here is a chart of the testing results on top of the original Hullforms prediction.

I thought they matched pretty well all things considered. The big "hump" predicted by the low speed professor never happened with my AF4 even though I went looking for it with several test runs in that speed range. Perhaps if you are properly prepared you really can use the Hullforms charts to predict speed for new hulls or effects of weight and trim.

Note that the MW12 and MW15 lines don't agree above "hull speed". (They were for all purposes identical up to that speed.) I think they should agree and can't think of any reason why they don't. I thought when I did the MW15 tests that the Thrustometer might have been binding somewhere to give the odd results but I ran that motor a second time with the same results. To be sure I gripped the Thrustometer together with my hands which sprung the scale beyond the range of the test and it bounced right back to zero freely when I released pressure.

Secondly it is interesting to wonder where all the horsepower goes. Only about 30% of the rated power is used to push the boat forward.

So I'm waiting for an Einstein to show up to explain it....

NEXT TIME...

...I'll show a rot repair that is not approved by Woodenboat.

MAYFLY12

MAYFLY12, ROW/SAIL SKIFF, 12' X 4', 120 POUNDS EMPTY

Mayfly12 is a small general purpose row/sail skiff based on the lines of the traditional flat iron skiffs of 100 years ago. By that I mean she has a nearly vertical stem, flaring sides from the midsection to the stern, and a raking stern. And she has quite a bit of rocker as did the originals. Mayfly12 is made from two sheets of 1/4" plywood and two sheets of 3/8" plywood. The heavier plywood is used to make a stiff bottom although one might save 20 pounds by using 1/4" plywood all over. I think the popularity of 12' skiffs is that they are usually all that one can cartop solo. Beyond that size and you should use a trailer. Once you have decided to get a trailer you might as well go to a 16' boat which is usually the most boat one can manhandle solo in the water. Sailboats larger than 16' are getting out of the "impulse" catagory and you should do some serious thinking before building one. Lightweight and simple boats like canoes and rowboats can be cartopped successfully at almost any length provided they weigh less than 100 pounds.

Here is the prototype boat by Mike Cerio in New York. There were at least two other Mayfly12's built but I did not get this short of photo so kept carrying the boat as a prototype. One of those boats was built with a daggerboard in lieu of the leeboard and it sailed quite well. This might have been Mike's first boat, certainly not his last:

I've kept the sharpie sprit sail that might have been found on a traditional skiff 100 years ago. It requires no store bought fittings to work well and its simplicity means it will work well most of the time. Its only real drawback is the 16' mast it requires. Unlike the traditional boats, I have used my favorite pivoting leeboard and kickup rudder so you can sail in shallows with no fear. And this boat has buoyancy/storage boxes fore and aft to allow self rescue of a capsized boat. By the way, to reboard a boat like this after capsize you usally need to scoop some water out of the cockpit before trying to climb back into the boat, and you usally must reboard over the stern. These boats are often too light to accept the weight of a man trying to climb over the side without capsizing again. The bailing is needed to rid the boat of water sloshing from side to side causing an uncontolled roll that might lead to another capsize.

Plans for Mayfly12 are $25. No jigs or lofting required. Uses old style glue and nail construction for the most part, but has taped seams on the side/bottom joint.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

Here are the prototypes abuilding that I know of:

The Alabama Skat is in the paint stage:

The Texas Ladybug is starting to look pretty roomy:

Am upside down plywood box I'm told is the true 16' Shanteuse (at last) is going together in Tennessee.

The Colorado Trilars looks ready to go:

Also there is an Otter (long narrow rowing boat patterned after the Pete Culler Otter) nearly done in New York. Builder is making special oars now.

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)