Gary Blankenship launches his brand new Frolic2 into the Water Tribe race. Read all about it at Duckworks Magazine.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Apr04) This issue completes the essay about figuring how much sail area your boat needs. The 1May04 issue will repeat the all important bulkhead bevels essay.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

THE 15TH MIDWEST HOMEBUILT BOAT MESSABOUT will take place at Rend Lake in Southern Illinois on the weekend of June 12 and 13. Remember that lots of folks come on Friday and leave early Sunday. Take I-57 to exit 77W and then follow the signs to the Gun Creek Recreation Area. Camping at this Corps of Engineers facility is $10/night and that includes the ramp fee. There is no schedule of events except a pot luck dinner in the campground on Saturday evening - we wing it. This year some of us have reserved the campsites on the water of the two middle camping loops so look for us there if we aren't at the boat ramp.

|

Left:

Gary Blankenship launches his brand new Frolic2 into the Water Tribe race. Read all about it at Duckworks Magazine.

|

|

|

FIGURING SAIL AREA 3

TO REVIEW...

...We are trying to calculate how much sail a boat can handle. First we want to calculate the force on the sail required to capsize the boat. We started with this picture of a sailing boat in balance:

We can write the basic balance as the sail force S = W x D / L where W x D is the "righting moment" of the hull and D is the distance between the center of the sail area and the center of the leeboard (or keel or centerboard, etc.) area. W is the total weight of the boat with everything on board. L is often called the "righting arm" and changes as the boat rolls and is fairly difficult and tedious to calculate. But the free program Hullforms can handle it. To use Hullforms one must first model the hull in three dimensions. In the last issue we showed the model for Picara but this essay will focus on smaller boats. This is my Hullforms model of the 14' boat Ladybug (the prototype is well along in construction down in Texas):

Given the hull lines and a weight/center of gravity information Hullforms will calculate the value of L and graph it for various values of heel as when the hull rolls. Here is the graph for Ladybug at 400 pounds weight and with the cg 24" off the bottom. This is about the lightest I would expect a loaded Ladybug would sail at complete with a minimum crew. I took a stab at the cg location.

Here Hullforms is calling the righting arm "Gz" instead of "L". The maximum value is .76' so the maximum righting moment of the lightly loaded Ladybug would be .76 x 400 = 304 ft-lb.

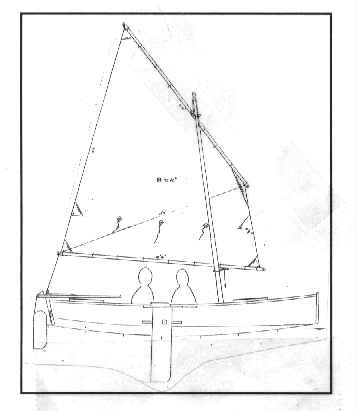

Here is a picture of Ladybug's sail rig:

The distance between the sail area center and the leeboard center is about 9'. So if we solve for the maximum allowable sail force we would get S = 304 / 9 = 34 pounds. If the force on the sail exceeds that amount then the lightweight Ladybug will roll past the point of maximum righting moment (at 20 degrees heel according to Hullforms) and continue to roll until the force on the sail is relieved.

Ladybug's sail area is 74 sq ft so the average pressure on the sail at this condition's capsize point is 34/74 = .46 psf.

Now the idea is to relate that sail force to real life conditions. Remember this chart which shows sail pressure vs wind speed at three values of "sail efficiency". I always advise using the C=1.5 value when using this chart.

.

Using the above chart it appears that the pressure of .46 psf happens at about 9 knots.

"Not a lot of wind," you say. "Almost any boat will take more wind than that." I agree. And so can Ladybug.

THE EFFECT OF HIKING...

The smaller and lighter your boat is, the greater the effect of your weight on its sailing. You can dominate the boat with your weight. You will weigh more than many of my boats.

Anyway, the the above case has its weight centered on the hull because that is how Hullforms does its math. At the point of maximum righting moment the situation with Ladybug would be something like this:

Now let's take the perhaps more common condition of the skipper sitting to windward on the bench seat. Not exactly hiking in any extreme way, just sitting on the bench on the windward side. In this example I will assume the boat weighs 200# and the crew weighs 200 # sitting to windward like this:

Now the righting moment is 552 ft-lb, up from 304 ft-lb, just because the crew has slid his butt to windward. 552 ft-lb means a sail load of about 552/9=61# for a sail pressure of 61/74=.82 psf. From our chart that happens at a wind speed of about 12 or 13 knots which is getting well up into the whitecap wave area, a visual sign that it is time to reef.

Now let's say you have an adventurous pal who wants to sail with you. He adds another 200 pounds to the effort like this:

Now the righting moment is all the way up to 952 ft-lb. Sail load required to capsize the boat is now 952/9 = 106 lbs which is 106/74 = 1.4 psf for this 74 sq ft sail. That happens at about 17 knots. Now the wind is really starting to blow! Your adventurous pal says, "No problem." and grabs a rope leading to the masthead and steps out on the rail with a trapeze, like this:

Now we are really getting up there. Righting moment with the big guy on the trapeze is now 1752 ft-lb! That figures to be 195 lbs on the sail for an average sail pressure of 2.6 psf. That happens in a 22 knot wind.

What happens if that 22 knot wind suddenly drops back to 9 knots? Most likely the big boy on the trapeze will get a big dunking. But he doesn't care. He hangs a bigger sail so he can go back on his trapeze in that light wind. How much sail does he hoist? You can figure it out. Assuming the bigger rig now has say 12' between sail and leeboard centers (just a wild guess) then the sail force at capsize will be 1752/12 = 146 lb. At 9 knots the sail pressure is about .5 psf. So the new sail needs 147/.5 = a whopping 292 square feet! Most likely you aren't going to see anything like that on today's boats but I think in the old days of the racing sandbaggers such a rig was possible.

But you can see that it is possible to figure it all out, at least approximately.

NEXT TIME...

We'll rerun that bevels essay.

ORACLE

ORACLE, LIGHT ROWBOAT, 15-1/2' X 45" X 80 POUNDS

Oracle might have been called Roar3. It is a bit longer and lower than Roar2 so it looks sleeker. It is actually closer in shape to my Toto canoe. I'm pretty sure it is a visual improvement over Roar2. Hard to say if it is a practical improvement. Being lower sided it might seem less secure but then again my Roar2 has never taken water over the wale in the ten years I've had it and maybe I've been hauling around excess freeboard. Max Wawrzyniak of St. Louis made the prototype. We rowed our boats side by side on a good day recently. I'd say the Oracle was 1/2 mph faster all around going about 4 mph at cruise and 5+ mph on the gps at full effort. It should float two adults quite nicely.

I'd like to point something about the way I draw the line on many of my boats. I make card models of my designs which help me check the panel expansions and allow me to get a 3D check of the shape. The models are done in the same scale as the blueprint, in this case 1/8 and the model is fairly large. So I knew that Oracle has nice curves all around. But if you look at the end view in the lines drawing you see all straight lines! In a way this is a throwback to the original "instant" boats which had hull panels made from straight saw cuts. It is easy for a designer to make the jump to more flexible shapes, that is hull shapes which can look like about anything you might imagine being made from plywood. Back when I started drawing boats I noticed some of the nicest shapes in 3D had end views made totally of straight line segments. Don't ask me why. Not only does that give a nice shape, the designer's job is simplified. For example, with Oracle I might start by drawing the top view. Then I might sketch in the side view needing nothing more than an idea of what the stem, midsection, and stern will look like. Next I draw the end view which will include those elements connected by straight lines. In normal mechanical drawing it only takes two views to totally define an object. So without even drawing the side view of the boat the shape is defined. It only remains to go back and figure it out and adjust the top view, etc., etc.. Happy is the designer who gets it right the first time through.

Oracle is built with taped seams using four sheets of 1/4" plywood. No jigs, no lofting.

Oracle plans are $20 when ordered direct by mail from me.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

The Texas Ladybug is getting details (Toto in background):

Out West the Picara project gets its bottom. Winter shifts work to sailmaking indoors:

The Deep South Skat is getting its brightwork:

Another Picara, this one with a 1' stretch in the middle, going together in Arkansas. Sailmaking right now.

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)