Charlie Ballou's Roar2 visits Canada.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15dec05) This issue continues ballast calculations. The 1jan06 issue will continue the subject still again.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Charlie Ballou's Roar2 visits Canada.

|

|

|

Ballast Calculations 2

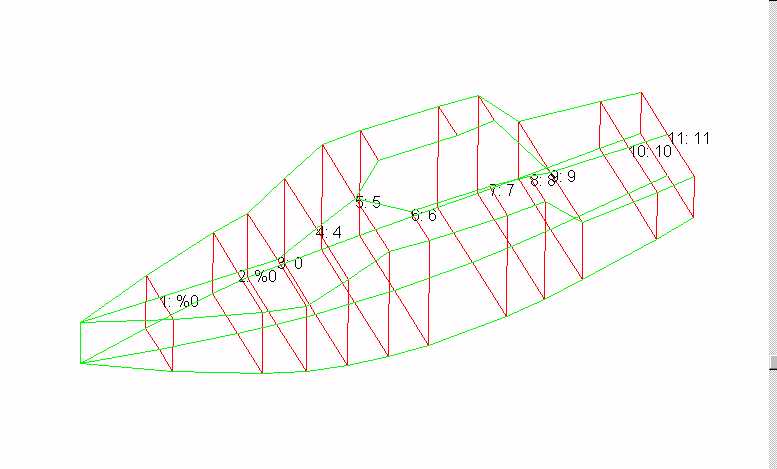

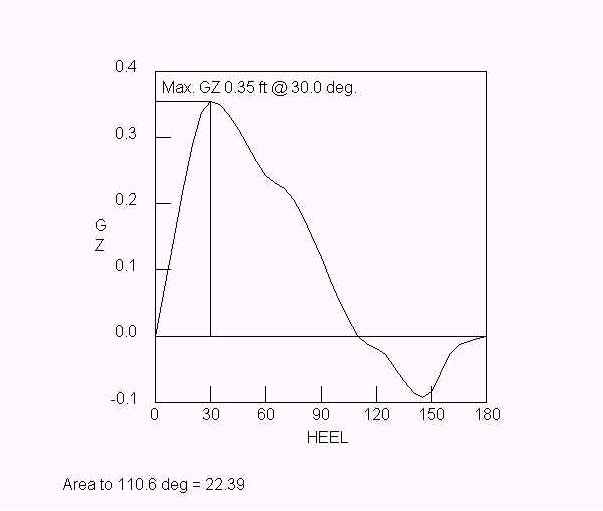

To recap a bit, last issue we used this Hullforms model of a new design called Robbsboat...

...to solve the problem of finding a center of gravity for the hull that will allow "self righting".

The result was that if the cg were 17.5" above the base line (which passes through the very bottom of the boat) then the boat would self right from a 110 degree roll.

OK....

...how do we find a ballast that will put the cg at that 17.5"? It isn't hard at all to figure but you will see there is a lot of guesswork involved because we will be guessing at weights of the parts of the boat. Here is a side view of an empty Robbsboat with the major elements roughly weighed and located:

It is important to get the sail rig involved since its weight is up high and will have a very large effect on the total cg location even though the weight of the rig is a small percentage of the total weight.

So here we have guessed at the weights of all the major components, including a grand guess at the "hull weight" at 450#. There is lots of room for error here but you have to start somewhere. A really complete job of this would include weighing each item as it is built and updated the weight/cg calculations constantly. Given our first guess at the weights, we also measure (roughly) where those weights would be centered above a baseline which in my designs is always a line running through the very bottom of the hull. Then we can make a spreadsheet (although my spreadsheets are usually done in pencil on the back of the envelope). Here is a neater spreadsheet of Robbsboat at this empty stage:

The "Z" number is the distance of the item's weight above the baseline (in inches). The weight is in pounds. The WZ factor is the weight multiplied by Z. At the bottom we add up the total of the weights and the total of the WZ's. Then divide the total WZ by the weight to get an "average" Z figure. That will be the location of the cg of the empty hull above the bottom. Here is works out that the cg of the empty rigged boat is 23.7" above the base line.

I should mention that I usually place the cg of the empty hull structure in the middle as if the boat were a tube of plywood. Then the item called here "double bottom" is the weight of an extra layer of plywood that this hull has on its bottom.

Let's add some goodies. A crewman at 180 pounds is sitting on the bottom such that his personal cg is 15" above the bottom. And a 50# motor that is hoisted out of the water with its personal cg 24" high.

I've also shown where I hope to attach the ballast but we will get to that detail later. The spreadsheet for the rigged hull with its minimum crew is now like this:

Now the cg is at 21.7" and we need to add ballast to bring that down to 17.5"

Pretty easy to figure with a spreadsheet, just keep plugging in ballast numbers until you get the desired cg. Like this:

So with the ballast placed as shown it will take 230# of ballast to make Robbsboat right from 110 degrees roll. Even without the spreadsheet it is a quick figure on a piece of paper.

You might ask "230# of what?" The answer is 230# of anything as long as it can be located 3" above the bottom as guessed at. (Lower is better, of course.) It could be a box of water but I don't want to start that argument again. Here is how I would approach it. Lead weighs .4 #/cubic inch and steel weighs .3 #/cubic inch. So if the ballast is lead you need 230/.4=575 cubic inches of it. In steel you need 230/.3=766 cubic inches. If you want lead you will need to round it up and melt it to some convenient bars. I would bolt the bars to the two main bulkheads as shown, say in six 39# bars. Each bar would be 96 cubic inches which might be 36" long, 4" high, and .66" thick. That way you can horse them around yourself and move them from bulkhead to bulkhead as you need to trim the boat level. In other words you might end up with four bars up front and two aft, whatever is needed. So you see the convenience of bolting to those bulkheads. If the ballast were bolted to the bottom, especially to the outside of the bottom, there would be a real gain in stability. But you also have holes through the bottom.

Myself, I would not mess with lead. I would use steel, say six bars of 128 cubic inches each. So these might be 32" long, 4" high and 1" thick, or something convenient such that you can have the steel man cut them to final size before you pick them up.

(I should mention that the problem of fore-aft trim can be solved in exactly the same way using X meaurements (fore and aft on the hull) instead of the Z measurements. Hullforms also will solve for you the proper X location of the total cg required for level trim.)

You can see from the spreadsheets some of the traps you might fall into to upset the cg calculations. If the crew sits on the aft deck his personal cg goes up high and now the spreadsheet looks like this:

Now she won't self right until he gets his butt back inside and on the floor. Similarly if he straps his gear to the decks and not stow it down low on the floor. By the way, if you insist on sitting up high and be self righting as before then you will need 500# of ballast instead of 230#. Big difference.

A long time ago Phil Bolger was doing these figures on a steel hull schooner. He said the real killer there was in the use of canvas sails that would soak up many many pounds of water in a storm and make the boat top heavy. I don't think Dacron sailcloth soaks water much, if at all.

Next time.....

Robbsboat

ROBBSBOAT, SAILBOAT, 15' X 4', 550 POUNDS EMPTY

Robb really probably wanted a Matt Leydon cruiser like Paradox but was put off by the complexity and small size. It has been a while since I saw Paradox plans but I think the "complexity" of the design is mostly in the details that made such a small boat livable. And maybe the only way to make a small boat like this work well in the Paradox fashion is to install all those details. However, my feeling is that almost no one is going cruising the way that Matt does and can get by without many of those details. My feeling is that Matt was able to make those trips in his little boats by very careful and patient planning and lots of experience. And if anyone were to ask me if this new boat is safe for ocean travel my answer would be a very quick and loud NO. In the right hands, like Matt's, it might be but it is the old case of "If you have to ask, the answer is NO." because the question demostrates you don't have enough experience to start with (like me).

But for a couple of days cruising on Kentucky lake, etc. by a small nimble person, it might work well, and that is what most of you will do if you are lucky. So the idea of Robbsboat is a small cruiser, totally enclosed, you sail it from the inside, you sleep in it, and it is supposed to take care of you and be self righting. Robb wanted it really sturdy so we have all 1/2" plywood with a bottom of double 1/2" plywood. Conventional construction including the only time I have ever used internal chine logs at Robb's insistance. That heavy plywood makes for a heavy boat - say 550 pounds stripped. The boat is supposed to be OK up to 1500 pounds total so a lot of gear can be stuffed inside. Some will think this is a two person cruiser, but they won't think that again after trying it on for size. If you tell someone they won't cruise with wife/girlfriend more than once I suppose 100% of them will disagree but you would be right for about 90% of them, so the boat will be a success 90% of the time. Much better than a really big boat that ends up being the wrong boat 90% of the time.

The sail rig shown is probably too large but then again it depends on the person and his cruising area. It is quite easy to reef or switch to a smaller sail since it is easy to get a balanced lug tuned up.

Eleven sheets of 1/2" plywood with conventional construction.

Plans for Robbsboat are $30 until one is built and tested.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

The out West Picara is I am told done to the point of using it as a powerboat:

The down South Picara is more or less complete now. Should have an updated photo soon.

This long and lean project is a 19' version of Toon2. Shown here on its first sail in very light winds. We will wait a bit longer to get a sailing report in stronger winds.

A Vector builder is keeping a website of the project at http://www.geocities.com/michsand@sbcglobal.net/ and here is a photo of his boat on its first sail, just before the storm hit. I also have photos of a Vector completed by Pete Mohylsky in Florida. Hopefully a report soon:

Here is a Musicbox2 I heard about through the grapevine.

We have a Philsboat going together in California:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)