Chris Feller's lug rigged AF3 at the Rend Lake messabout.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Jun05) This issue will continue the series about designing Bobsboat. The 1 July issue will present the goings on at the June Rend Lake Messabout.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Chris Feller's lug rigged AF3 at the Rend Lake messabout. |

|

|

DESIGNING BOATS 7

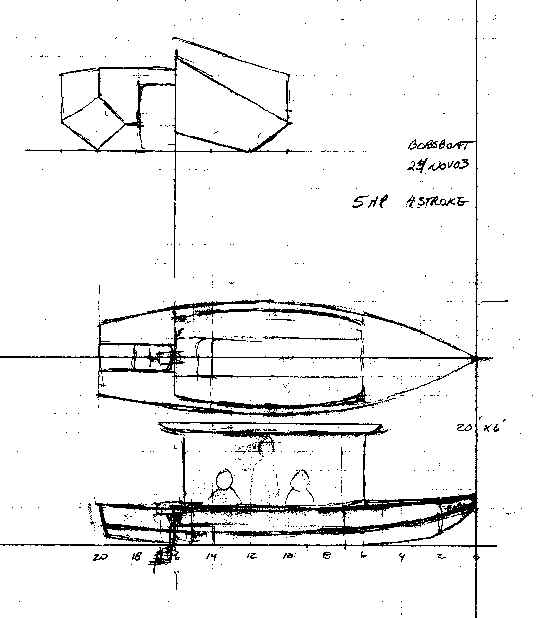

Now back to Bobsboat. We have drawn the lines, measured displacement, and determined the true shape of all the plywood elements. Now we are going to make a card model of the project. Might seem old fashioned but there are several good reasons for doing so. One is to make sure all the parts fit. Second is to get a good look at it and see it appears in real life as we thought it might. Also we will get a first hand impression of its structural qualities.

First thing to do is to draw all of the panels in scale. The bulkheads and transom and forms will already be done in the three view drawing. The bottom, side, and bilge panels that we expanded with the computer must be drawn out in scale (1/12 scale in the Bobsboat example). Here is how I do that: I draw them to scale on the old type of fan fold computer paper. That way I can get a really long white paper with accurate edges to use as reference lines. I draw them as accurately as possible with no thought to things like butt locations or dimensioning problems. Later these shapes will be transfered to the working drawings that will go to the builder but right now we aren't going to worry about that.

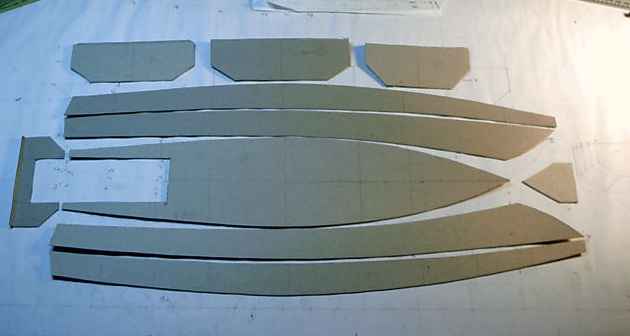

Next the scale panel drawings are placed over card stock and the shapes transfered to the card with pin marks right through the paper to the card. The pin marks are then connected on the card to reproduce the shape. Errors can creep in here pretty quickly but remember the original shape drawings are not changed. In this example I used heavy card stock that came in packages of blueprint paper but one of my favorite materials for a model is the thinner white card used for posters and such that I find at the drug store. After I get the shapes onto the card, I cut them out like this:

As with the real boat you need to mark the parts with centerlines and the locations of bulkheads and forms. This is just like building the real thing at this stage. You can get a quick check of your expansions by looking to see if joining edges all have the same lengths. Because of the scale and all the transfering of lines the model won't be as accurate as the real thing.

The assembly is not like building the real thing. On the real thing I would screw the sides to the center form and install the other bulkheads and forms by pulling the ends in with ropes and adding the elements one at a time. With a card model I tape all of the cross elements to one side at first, like this:

Then working from the stern I tape the cross elements to the other side and by the time I get to the bow I have the makings of a boat. Like this:

It will still be wobbly but taping the bottom to the cross elements will stiffen it up a lot, as it will with the real boat. I also added the panels that will form the walls of the motor well (by the way when I measured up my motors I found it takes a well 2' wide to allow the motor to turn fully.)

Now we will tape in the bilges. Usually the hardest part of the job, as it is with a real boat. I start by taping it in the middle of the boat, then work out to the ends. Takes a bit of time. If there is an error in the shapes you will notice it here. I thought the Bobsboat bilges fit pretty well and think the expansions are correct:

Next flip it rightside up and install some seats:

And then some decks:

Looks like a Bobsboat to me! Sometimes at this stage you will see things that you might want to change. I have been doing this for about 15 years now and one thing to watch out for is the proportions. Hard to see that as well in a computer rendering. In particular I have found the fore deck needs to be longer than you might first draw in a three view. I have this theory that your eye can quickly gauge the volumes under the fore deck and the stern deck and wants them to be equal for some reason. In a boat with a square stern and a pointy bow, that bow deck will look better if it is longer that you might first suspect. Anyway, I see no need to alter the Bobsboat. That stern well is looking quite large but right now I see no other way to do it. If you make it narrower you can't swivel the motor fully. If you decide to plate in the bottom opening leaving just a small hole for the motor you won't be able to raise the motor up without resorting to a lot of claptrap. As speaking of traps, if the water gets trapped there while the boat is in motion, the water level in the well can raise alarmingly, maybe right over the bulkhead into the boat depending on the speed and waves. How high can it go? On Birdwatcher water will spurt out of the top of the centerboard well at most any good boating speed and in a chop it will shoot right out the top of the boat! Imagine sitting next to a washing machine running with its lid open and you get the idea. So with Bobsboat I'm keeping it wide open on the bottom and stern to let the water flow through and out. I hope.

At this point it is a good idea to look for "soft spots" in the structure. Not sure but with Bobsboat a partial frame in the center of the cockpit might help stiffen the bottom up, always a problem with a long open cockpit. But if you are clumsy you will trip over it several times a day so a valid approach, especially with a prototype, might be to build the boat without with the idea of adding it if bottom flex is troublesome to you.

Finally, take your model and try to twist it. If it twists easily so will the real thing and that ain't good. This is a problem mostly with square ended open boats like jonboats. Best solution is to box in the ends with decks as done here.

When we return to Bobsboat I think we'll take a try at predetermining the bevels of the bulkheads, etc.

NEXT TIME: We'll review the 2005 Rend Lake Messabout.

Roar2

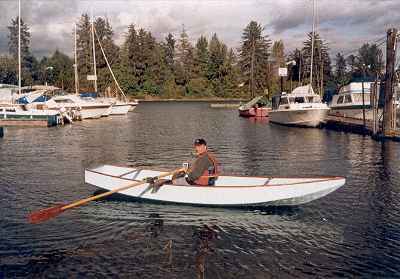

ROAR2, ROWBOAT, 14' X 42", 75 POUNDS EMPTY

Roar2 is a modification of the original Roar which had a plumb stem. After I had designed, built, and paddled Toto with its V entry bow I went back and cut the lower plumb bow off my Roar and converted it to a Toto-like bow. So Roar2 has a deep V entry which is carried well aft. About two feet of the sharp bow is immersed and provides a skeg action forward. As a result Roar2 behaves well in all aspects of wind and waves and is more capable in rough going.

The new shape makes a different sound - a "swish, gurgle" as it cleaves the water, where the original Roar has a "tap, tap" sound typical of boats that go over the water instead of through it. I suspect the original shape is slightly faster in smooth water but the new bow has the edge everywhere else. She'll row at 4-1/2 mph with medium effort using the 7 foot oars detailed in the plans. Adding a passenger to either version will hardly slow her, although acceleration and deceleration are affected.

Walter Kahlhammer built a clipper version of Roar2 without the bracing shown across the wales and reports his boat was still rigid. But the aft cross brace is almost mandatory for use as a passenger's back rest. Without it the passenger will soon tire and lean to one side or slide aft to rest against the transom, throwing off the trim in a way that will drive the oarsman crazy. (Walter uses a removable passenger seat.)

These are excellent camping boats, light enough to solo cartop, large enough for much gear and with a flat bottom plank long enough to sleep on while the whole rig sits upright. Kevin Garber took a Roar2 on a three day row of the Big Bend region of the Rio Grand, seeing no humans from put-in to take-out. He brought a folding chair, a barbacue, and a tent fly with poles. In camp he set up the fly over the hull and slept in the boat. Here is a photo of me in my old prototype (still use it) demonstrating proper nap position:

I have found some more photos builders have sent. I'm sure I've forgotten where I've stored others. Here is Charlie Ballou rowing off into the Massachusetts sunset:

Here is Greg Rinaca in Texas:

I think this is Lincoln Ross but I'm not sure:

And Brian Walker in Canada:

Plans for Roar2 are $15. Taped seam construction from four sheets of 1/4" plywood. No lofting or building jigs.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

The AF4G is done and launched. Writeup after testing:

Garth has the big Cormorant to the point where his kids have taken it over and he can't get it back.

The out West Picara has its roof and some major sail rig bits done:

The down South Picara is getting its innards done.

This long and lean project is a 19' version of Toon2. I don't have the drawings done yet. The builder is working from preliminary drawings and is about to pass me up. MDO plywood looks like cardboard now but it isn't.

We have an experienced builder building a Mayfly16:

This is a slightly modified Veep14. I'm told the sheer is raised a bit and the stern given a bit of flare but the bottom is per the plans. Waiting for a test:

A Vector builder is keeping a website of the project at http://www.geocities.com/michsand@sbcglobal.net/ but in the meantime I got photos of a Vector completed by Pete Mohylsky in Florida. Here he is fussing with his sail. Hopefully a report soon:

And a Polepunt is nearing completion in Poland, of course:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)