Another yellow boat in Chicagoland. Chris Feller's new Piccup Squared awaits its first dings.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15aug06) This issue will start a series about panel stiffenss. The 1 September issue will rerun the important taped seam essay.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Another yellow boat in Chicagoland. Chris Feller's new Piccup Squared awaits its first dings.

|

|

|

Panel Stiffness 1

FIRST, THE BASIC BASICS...Let's say you have a bar or stick of material that is 1 square inch in cross sectional area. You mount it in a testing machine that will apply a load in tension and will record that load plus the amount the sample stretches during the loading. Like this:

If you run the test until the sample fails totally you might see a curve of load/deflection that looks like this:

All structural materials act sort of like this with variations. To walk you through what is happening, the testing machine starts to pull on the ends of the bar and the machine records the load and the deflection of the end of the bar that corresponds to that load. In the first phase of the stretch, the load and deflection go up in a straight line. Double the load and you get double the stretch. Until you hit the "yield point" of the material. Then something happens. If the material is brittle, like cast iron (or a weld), it will break all at once. But if the sample is not brittle, say like soft steel or aluminum, it will continue to take more load. However it will deflect a lot more than it did per unit of load than it did up until the yield point. Some materials like the softer steels used in building construction can stretch beyond the yield strength to twice that strength, with enormous deflections. Such structures can give a lot of warning when they are overstressed and that can be a safety factor. In general if you strengthen a metal by heat treatment you can get dramatic increases in the yield strength but not so much in the ultimate strength.

Some typical values of common materials used in a boat might be:

Stainless steel, yield stress 78,000 psi, ultimate stress 125,000 psi

Aluminum: yield stress 60,000psi, ultimate stress 68,000

Spruce premium lumber: yield stress 7000psi, ultimate stress 10000psi

I got these values out of an old handbook. The values can be misleading in that there are many different alloys of metal and qualities of wood so that your mileage may vary.

BY THE WAY...

If the machine pushed down on the sample to compress it instead of stretching it you usually get a similar curve going in the other direction. Sometimes the idea of "ultimate compressive failure" can raise an argument say when you have a soft metal that simply mooshes down (a technical term I don't have the time to explain) such that it never really falls apart in compression. But most metals have a yield strength in compression that is about the same as the tensile yield strength. Wood is different, at least in my handbook. Spruce has an ultimate compressive strength of just 5600psi, about half of its tensile ultimate.

IF THE LOAD IS REMOVED...

... before reaching the materials yield strength, the bar will shorten as the load is removed right down the original load/deflection line until it has zero deflection again. Like this:

The slope of that initial line to yield strength is a big deal. Think of it as a "spring rate" in that your bar stretches so much per unit of load. The slope of that curve is called the "modulus of elasticity" and is usually given the symbol of a big "E". For example the E for steel is about 30e6, Aluminum about 10e6 and spruce about 1.5e6. Engineers use these values to predict deflections but you might just think of it as saying "steel is three times as stiff as aluminum, and twenty times as stiff as spruce" but remember that the number is hung on a square inch sample cross section, and then remember a cubic inch of steel weighs about three times as much as aluminum and twenty times as much as spruce. So now things can get blurred in an interesting way.

Here is another something interesting to those of us who are easily entertained. The density and E of metals is hardly affected by the alloy or heat treatment of the metal. So if the shop guy tells you he will increase the stiffness of your spring by heat treating it, something ain't right.

AS AN ASIDE...

If you load the bar past the yield strength and then remove the load, the sample does something interesting. It returns down to zero load but retains a bit of deflection - it has a permanent stretch! Like this:

.

Then if you load the sample again it will go UP the red line it just came down until it reaches the the line to the ultimate load again. Then its new "yield" strength is going to be higher than its original yield strength. I suppose it is being "work hardened".

But in general things are not designed to be used past the original yield strength. They can go up and down that same line millions of times without any added stretch as long as the yield strength is not exceeded. When I was in the missile factory we ran things right out to the "ulitmate" strength all the time since the missile was supposed to be on a one way trip - we didn't care if it stretched along the way. But ordinary things aren't designed that way. They are supposed to be reused over and over.

I don't know when this elastic behavior was first discovered but most likely it was in mid 19th century. Since then almost all structural theory is wrapped around this linear elastic behaviour and it works quite well.

NOW WE MOVE ON TO ANOTHER BASIC...

Let's say a fellow puts a 2x4 across a pair of saw horses and sits on it, like this:

The board deflects into a curved shape.

Now here is a big idea that engineers use to solve their problems. If the board is now curved, and you have a material that has linear elastic behaviour as discussed above, then the stresses inside the board can only be like this:

What has happened is that the only way the board can curve in the way shown is to have the top fibers get shorter (by compression) and the bottom fibers get stretched ((by tension). In this simple example the total amount in compression has to equal the total amount in tension. Fibers away from the top and bottom MUST lengthen or shorten in the pattern shown in order for the board to keep its continuity. The fibers in the middle, on the "neutral axis", don't change length so suffer no stress due to stretching or compressing.

Actually with the info given so far, we can calculate the stresses in the board under the man's weight. The bending moment (or torque) under the fellow's bottom is 100# times 48" or 4800 inch pounds. It can only be resolved in the center of the board like this:

Note that the answer is only dependant upon the geometry of the things, not on the material used. So the answer would be the same in steel, aluminum, wood, or any material with the 1.5" x 3.5" cross section and linear elastic behaviour. So the fellow has 3660 psi stress under his butt. No sweat to aluminum or steel but it might break that cheap 2x4!

We will get back to this in a couple of issues. But...

NEXT TIME...

...We'll rerun the important taped seam essay.

Cormorant

CORMORANT, CABIN SAILBOAT, 32' X 8', 2500 POUNDS EMPTY

Cormorant is the largest boat I've ever designed. I always warn folks to think twice and three times before building a big boat because you can buy a good used glass boat for less, maybe a lot less. But a homebuilt boat can have features that aren't available in a production boat and so it is with Cormorant. This one is really a 20% enlargement of Caprice.

Straight enlargements rarely work perfectly and so it was with Cormarant from Caprice. (Don't forget that Caprice was an enlargement of Frolic2, etc., etc., right on down to my Toto canoe.) In this case I narrowed it from a straight enlargement to keep the width within simple towing limits since this large boat is supposed to live on its trailer most of the time. The layout is quite similar. The idea is that the adults sleep in the center cabin and the kids sleep in the forward room.

Like Caprice, Cormorant has water ballast, over 1000 pounds of it. Total floating weight with family is going to be up to 4500 pounds. You don't tow a boat this large behind a compact car but I think towing this sort of weight is common today, all done with expensive large trucks I'm afraid.

The sail rig looks pretty modest with a 207 sq foot main. I'll bet it is enought since this shape is easily driven. I don't think you can go any larger and still hope to handle it without extra crew and gear.Tthe lug sail shown is similar in size to Bolger sharpies and they seem to get by OK. Experience will show if it is too big/too little.

Constuction is taped seam, with no jigs or lofting. Unlike smaller designs this one does not come with a plywood panel layout drawing. Over the years I've learned two things about the ply layout page. First is that almost no one uses it. Second is that with a larger boat the work of finding and drawing and fitting all the pieces to the boat on scale plywood sheets overwhelms all the other work. So part of the deal with doing the design was that there would be no plywood layout drawing. However this is still a true "instant boat" in that all of the parts that define the boat are drawn in detail and you can scale them up on plywood, cut it out and fasten together with no need for lofting or a building form.

Garth Battista, who is a book publisher at Breakaway Books where he publishes sporting books including my Boatbuilding For Beginners (And Beyond), is a true boat nut and has worked himself up from dinghies and canoes to the big Cormorant. He took it initially on a quick shakedown run on a lake near his home and shortly later to Long Island Sound for a week with his family. Here are his comments:

"We had an amazing time living aboard Cormorant (christened "Sea Fever") in Provincetown harbor for 5 days. The tide there was rising and falling about 12 feet a day with the full moon. We'd be high and dry up on the beach for breakfast, swimming off the boat at lunchtime, walking the flats again by dinner. It was a blissful time for me and my wife and two girls. We moved around, took little sails here and there across the harbor (West End to Long Point, then to the lighthouse, then to the East End, etc.) anchoring here and there, usually just running it aground as the tide allowed and staying for a while. Many shells were collected, and tidal pools investigated. Of all the harbors I've ever seen, it is the most alive. It's a couple of miles across and fresh sea water flushes the whole place twice a day. The number of snails, clams, crabs, fish of all sizes, mussels, eelgrass, etc. was just mind-boggling. On high tides I'd go spearfishing (many attempts, no luck) where at low tide I'd been walking around.

We rigged a 8' x 15' white tarp with tent poles running crosswise as a canopy over our cockpit and hatch, supported along the mast folded down in the tabernacle, so we could escape the mid-day sun. Most days were hot and humid and mild, with only gentle winds. We rode out a nighttime thunderstorm with no trouble, just stayed up and watched the lightning. We attended a few wedding-related events, just walking ashore for one party, and for the wedding itself we returned late at night and rowed our dinghy out to the boat, our sleepy children just awake enough to get themselves aboard.

For our last two days we gave up the shallow-water life and sailed from P-town down to Wellfleet, about 7 miles, surfing along on gentle 3-foot waves with a following wind. We beached the boat at Great Island, walked the beach, had a picnic dinner, swam and played, spent the night, and left the next morning at 6 a.m. to beat the falling tide. Our weather radio mysteriously quit working that morning, so all we had was the prior day's forecast of 10-15 knot winds from the SW.

The wind had shifted into the west during the night, so we had to beat out of the harbor, and once we turned north to return to Provincetown, huge rollers were coming in off the bay, more or less directly into our port side, lifting us, rolling us, occasionally breaking and spraying water into the boat. We stayed well offshore to avoid the breakers in by the beach -- but with the falling tide it seemed that we needed to be nearly a mile out. It went from exhilarating to worrisome to mildly terrifying as we neared P-town and the wind kept picking up, past 20 knots to 25 and higher in gusts, and the waves just kept growing. The swells were in the 8-10 foot range, with a high percentage of them breaking at their tops, whitecaps everywhere.

But bless this boat! With its 1000 lbs. of water ballast, and the leeboard mostly up, we were able to bob and roll and slide over nearly all the swells. The worst of them were very steep and threw us sideways, maybe tilting us to 40 or 45 degrees briefly. We had two reefs in the main and the mizzen rolled down to about half-size, and still we blasted along on this nasty rollercoaster of a beam reach. It was the sort of trip that would be scary fun if it was just you and a buddy, but it's awful when you have your loved ones aboard, and you wonder who might get thrown overboard, and how you'd managed a rescue in the rough conditions.

Anyway -- the white knuckles got to relax as we finally made it past the P-town breakwater, and with great relief ran her aground out on the flats. The gale (or near-gale) continued to blow all day, kicking up 3 and 4-foot waves even in the protected areas of the harbor. The only boats we saw going out were an 80-foot schooner and a big whale-watch boat. A lobsterman we talked to later said he'd stayed in as it was too rough to check his traps.

We had a hell of a time taking the boat out and getting her on her trailer for the trip home -- but all worked out in the end, with the assistance of some very kind strangers; and I'm left with the memories of incredibly happy days. -- And an incredible boat.

All best, Garth

P.S. Jim -- I should also mention that on Sunday afternoon as we turned the corner from our run down to Wellfleet to the close reach upwind toward the inner harbor, the boat just drove perfectly. It seemed we made 40 degrees off the wind. That maybe wishful thinking, but it was an angle far better than I'd imagined a lugsail could manage. It was a joy to sail, in all conditions. My hat is off to you.

P.P.S. The number of people who came over to admire the boat and exclaim at its uniqueness, its coolness, its obvious functionality -- well, they were beyond count. "

Plans for Cormorant are $60 when ordered directly from me.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

The out West Picara is I am told done to the point of using it as a powerboat:

The down South Picara is more or less complete now. Should have an updated photo soon.

This long and lean project is a 19' version of Toon2. Shown here on its first sail in very light winds. We will wait a bit longer to get a sailing report in stronger winds.

Here is a Musicbox2 I heard about through the grapevine.

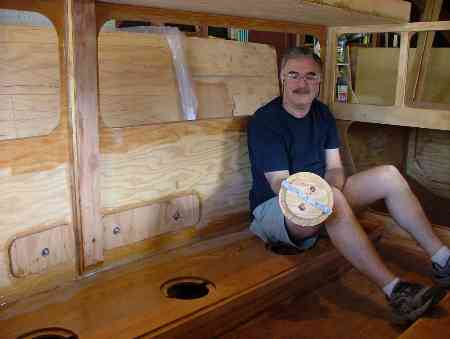

We have a Philsboat going together in California. You can see the interior room in this 15' boat:

And here is another Philsboat in northern Illinois:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)