Knockdown Recovery 2

RECAP....

In the last issue I presented an essay about knockdown recovery

demonstrated by Herb McLeod with his AF3. This year Max Wawrzyniak

completed an AF3 in St. Louis not far from here. One weekend we went

out for a boat camp at Calylye Lake. On that Saturday there was no

significant wind and we decided to take advantage of the calm

conditions by doing a practice capsize of his AF3 (shown below with a

classic 2hp Neptune mounted).

On reason I was looking forward to the test was to scope out the

situation which Norm Wolf ran into with his Normsboat where the

capsized boat floated nicely on its side and was easy to right but had

its centerline slot pretty close to the water. Here is a photo of the

situation.

Few knockdowns happen in calm conditions of course, and that open slot

might look inviting to a large wave. When I made the first boat like

this about ten years ago, a Bolger Jinni modified to have a small slot

top cabin, I was careful to add segmented hard covers over the slot

when sailing in rough conditions. I never capsized that boat and can't

say how it would have done. But I feel the slot was covered

sufficiently to minimize the effect of waves. I did similar designs

like Pencilbox and AF2 and showed the plywood slot covers on the

drawings but none of the builders built them. I'll admit that

hardcovers are a pain. Eventually everyone moves towards soft covers

and that is what Norm and Max use. I'm not sure how effective a fabric

slot cover would be in keeping the waves out but I'm pretty sure it

would be a lot better than nothing. Remember that the cover is not

supposed to keep the water out for hours but just for a few minutes

while the skipper swims around and rights the boat.

For any slot cover, the mast is something of a problem in that it is

mounted on the side of the slot and would need to protrude through the

cover if the cover were used while sailing. It was fairly easy to make

a slot it my plywood slot covers. I think someone handy with a sewing

machine could do the same with a soft cover but that is only

speculation.

THE CAPSIZE...

Here is what we did. The AF3 was beached and we removed the motor and

all the loose things, although Max is much better at secure stowage

than most of us. The boat was walked into waist deep water, parallel to

the shore, and anchors run out from the bow and stern. The halyard was

secured to the mast and its free end given to me close to the shore. So

I could pull the boat over with the halyard while the anchors held the

boat in place.

The sail was stowed to keep tangles to a minimum but the sail and boom

can have an effect on the result. I would expect the boat would be

slightly less stable due to the weight of the sail and boom up high.

Once the boat is knocked down the boom and sail can help float the boat

and keep the boat from going turtle. In fact that effect is really

strong with a lug sail who's yard acts like a float out on the top of

the mast. Then when it comes time to right the boat it is very very

important to totally release the sheet because if water pools in the

sail as you try to raise it off the water the weight of that water can

make the boat much harder to right. (There can be other effects.

Remember wind surfers? You never see them any more but 15 years ago

they were all the rage. One day I was out sailing when a young woman

fell off a windsurfer nearby. She climbed back on and raised the sail

with the rope. "Did you see that!" she exclaimed. "What?" says I.

"There were five fish in that sail when I pulled it up!" says she.} And

don't forget that if you raise the boat upright with the sheet tight

that boat might sail off without you!

Max sat in his boat in his usual sailing position while I tugged it

over. He has a tilt angle indicator on his bulkhead although it maxes

out at 40 degrees, I think.

I pulled it over and thought in a subjective way that the maximum

righting force came at about 20 degrees which is what I expected.

Almost any unballasted sharpie seems to behave like that. I continued

to pull until the cockpit coaming was about to go under and flood the

cockpit. Max said that was at about the limit of his gauge, 40 degrees.

I was surprised that the boat still had substantial righting ability at

that point unlike my old Jinni which capsized twice in tis career, both

times it seems like way before any water came over the rail. But the

AF3 was still hanging in there and you might be able to recover right

up until then. Max had covers over his oarports which leaked slightly -

a good indication that it is time to release the sheet although I can't

imagine anyone seriously sailing one of these over 20 degrees of heel

in a regular way.

Next I released the tension on the halyard so the boat rolled back

upright. Warning! If you ever do a test like this give the skipper lots

of warning because the boat rolls upright very quickly and the ride

inside the boat can be rather violent!

Max checked things over and all was OK for the test to a full capsize.

I tugged on the halyard and at about 45 degrees of heel the tension on

the halyard was about zero. Over it came and I grabbed the mast when it

approached horizontal and Max jumped out of the flooding cockpit. The

righting moment continued in a negative way indicating the boat might

turtle but when the mast tip hit the water it settled on its side like

this:

Max righted the boat in an instant. He said there was nothing to it.

Norm said there was nothing righting Normsboat and Herb said there was

nothing to righting his AF3.

Once righted Max climbed back into the boat using the step hole he had

cut into his rudder. It worked very well and I am going to show such a

step hole in all future boats. The hole has no noticable effect on

sailing.

Max bailed it out and that takes a while. There was no water in the

cabin or stern locker but it was maybe 6" deep in the cockpit. In a

real capsize this would be a critical time since the water in the

flooded cockpit would roll around with each wave and make the boat a

lot less stable. It is important to have a good bailing bucket handy

and secured to the boat if you are sailing in capsize conditions.

When it was all squared away we capsized it again so I could get an

idea of the effort needed to right it. Not much required. With Jinni it

took my weight on the leeboard to right the boat but with AF3 I never

got that far. When I waded around the stern I grabbed the chine and

pushed on the bottom and up she came.

WHAT I THINK IT ALL MEANS....

I'm going to draw a narrower slot in future designs and go back to

showing the plywood slot covers.

One question I have to ask myself is if a bit of added ballast will

make these designs self righting. Not with the crew inside because that

can be a very difficult situation to scope out in every way, but with

the empty boat righting itself after the capsize and the crew is

swimming. Then the boat self rights by itself before waves have a

chance to flood into the slot. The crew doesn't need to swim except to

get to the rudder toe slots and back into the boat. Then it is bail

time. From what I have seen the amount of ballast needed might not be

much, maybe less that 50 pounds. Maybe less if the weight is mounted on

the tip of the leeboard. But you can't always plan on the leeboard

being down and the tip ballast might make the board very hard to pull

up. You can of course see a great danger in such a boat in that it

might sail off without you very quickly so on second thought it isn't

such a good idea. Then again, that situation is no different from the

present where you must have the sheet loose and have a good grip on the

boat when it pops upright.

But it would not be a major effort to find out. I might check it out

using the Hullforms program but even better would be to wait until the

warm water returns and Max gets bored with sailing on a calm day. Then

we haul it over again and see how much weight is needed to make it

right by itself. Luckily Max is a good sport.

LADYBUG CAPSIZE UPDATE:

Chuck Leinweber of duckworksmagazine.com did a practice capsize at his

Texas messabout this past year, took photos, and wrote up the

experience:

"I wanted to add some notes to the pictures of the Ladybug capsize

test:

It's hard to tell, but the bottom drops off quickly here and the boat

never touched. Sometimes it looks like it might be sitting on the

bottom, but it was happily bobbing in the waves even when completely on

it's side. It took a surprising bit of effort to pull the boat over

even though it was entirely stripped of gear.

Once on it's side, the boat floated on the yardarm with the hull high

in the water. That is the tiller in the air since the rudder flopped to

starboard.

Now I start to try to bring it back up. I probably should have done it

the other way so that I could have pulled the leeboard, but I guess in

a real knock-down, you don't get to choose.

Now I'm grabbing the gunwale and am putting some weight on it. - that

did not work, so I climbed on the mast - at this point the yardarm went

under and may have hit the bottom. Anyway, I swung myself over the

side.....

...and hanging onto the gunnel, easily tipped the boat back upright.

I tried to simulate getting back in the boat in deep water by bending

my knees and pulling myself in with my arms only. This was surprisingly

easy.

There was a bit of water in the cockpit, but that was easily bailed. I

think the boat would have sailed that way unless it was very brisk.

Skip Johnson helped me bail the boat out. The hatches were built a

little oversized to accommodate an ice chest (yes, we are spoiled) but

only leaked a few tablespoons of water into the flotation chambers. Now

we pack our gear in dry bags when we go cruising."

MORE PONDERING...

If you are going to sail in capsize conditions you really need to:

...Practice a capsize until you can right the boat and get going again.

Practice usually happens in mild conditions and in real capsize

conditions things will be worse. Then again the fear factor in a real

capsize will help your strength and quickness.

...Make sure all your gear is well secured. If not you will lose it. In

this catagory would be important boat parts like your rudder and mast,

both of which may leave your boat if not well secured in position if

the boat is sideways or inverted.

...Keep bailing equipment handy and secured to the boat. I think that a

couple of scoops made from gallon jugs might be best, one tied to each

side of the hull so you won't have to reach across a flooded boat to

get a scoop. Should be large enough to bail a good amount of water with

one hand because you will need the other hand to hold on to the boat.

Should not be so small that it will take a long time to bail.

...Give a lot of thought to righting and reboarding the boat. I would

suggest having lines that allow you to pull down on the wale from the

bottom even if you can't reach the wale or stand on a leeboard. Also

seriously consider the slot in the rudder to give a toe hold to

reboard. Most smaller boats if swamped will be too unstable to reboard

over the side - the water in the boat will slosh towards you as you try

to hoist yourself over the wale, recapsizing the boat.

NEXT TIME...

We'll ponder power requirements.

Contents

Caprice

CABIN SAILBOAT, 25' X 6', 900 POUNDS EMPTY

About 15 years ago I built a Payson Canoe and used it for several

years before selling it. I replaced it about 10 years ago with my

Toto double paddle canoe. Toto has the same multichine cross section

as the Payson Canoe but I tried for a long lean bow which would be

better in rough water and more foregiving of bow down trim. I still

have that Toto, unchanged in any way since new, and still use it all

summer. Amanda Johnson demonstrates:

The Toto shape worked so well that I used it in other designs like

Roar2 and RB42. I tried it also in a sailing boat, the 20' Frolic2

(the original Frolic was narrower, more of a rowboat than a

sailboat). Frolic2 was unballasted with a small cuddy and I hoped it

would be a good daysailer and one man camping boat.

Bill Moffitt had built my Woobo design and funded a 20% enlargement

of Frolic2 that would have a cabin, water ballast, and a yawl rig for

cruising near the Gulf Coast.

The 20% enlargement idea went very well except that I had to deepen

the hull more than that to give some serious headroom in the cabin,

but it doesn't have standing headroom. Great empasis was placed on

ease of use and rigging. The main mast is short and stepped in a

tabernacle. There is a draining anchor well in the bow, a small

storage segment under the front deck. The mast tabernacle is bolted

to the bulkhead that forms the front of the sleeping cabin. There is

a utility room aft of the sleeping room. Water ballast tanks are

under the bunks and in the sides of the utility room floor, about 600

pounds of ballast as I recall. Aft of the cabin is the self draining

raised cockpit with storage volume under the deck. Finally there is a

self draining motor well across the stern. Construction is taped seam

plywood.

Bill couldn't start his Caprice right away but Chuck Leinweber of

Duckworksmagazine gave

it a try. He has the room and tools and smarts to tackle a project

like this with no hesitation. There weren't many changes from the

plans that I know of, the main one being adding a conventional

footwell to the aft deck which is designed to have a hatch type of

foot well as with the Bolger Micro.

Chuck trailered his Caprice up from Texas to our Midwest Messabout

this June and I had a chance to go over it, sail it for a couple of

hours, and watch it sail from other boats. Wonderful!

Chuck tells me it takes less than 15 minutes to rig the boat to as

you see here. As shown the boat has its ballast so you see it beaches

very well indeed. I asked about the ballast. He can flood the tanks

without power, just open the access plate, reach in and pull the fill

plug and let the water rush in. Since the tops of the tanks are about

even with the normal waterline he has to move his weight around to

keep the tank depressed long enough to completely fill. Then you

reach into the filled tank, replace the plug in the bottom, and then

replace the access plate in the top. There are two tanks to fill.

Are the ballast tanks worth the building effort? On a multichine hull

like this the tops of the tanks form flats that give places for bunks

and storage so that is good. When full the boat should have a very

good range of stabiltiy. Chuck's boat has never been in rough going

as I'm writing this so the effect of the ballast remains to be

proven. It has been capsized in a practice but the ballast tanks were

empty and the boat was empty with no crew, etc.. But the ballast is a

success from the standpoint that Chuck is able to tow his Caprice

behind a four cylinder pickup truck. My idea was to pull the boat up

the ramp and drain the tanks afterward by simply pulling the drains

plugs. But Chuck has found it best by far to empty the tanks before

recovering the boat at the ramp. So he uses a bilge pump in each tank

to pump them empty. I'd be worried about water ballast tanks on a

wooden boat from a rot standpoint and would be careful to open all

the plugs and access panels when the boat is stored.

(I should add that I think an empty Caprice will weigh about 900

pounds based on the plywood sheet count (eight sheets of 1/4", nine

sheets of 3/8" , five sheets of 1/2" and one sheet of 3/4"). But any

boat like this can hold an awful lot of gear and junk.)

Caprice has the tabernacle setup that I first saw on Karl James'

sharpie. The mainsail is 190 square feet, balanced lug. The mast is

fairly short, stowing within the length of the boat when lowered.

Chuck demonstrated putting up the mast, maybe a 15 second operation.

I've been drawing these for a while on different boats but this is

the first one I know of to get built and used. I'm greatly relieved

that is all works so well. Before you decide to tack a tabernacle

like this onto your boat, be advised that the tabernacle posts go

clear to the hull bottom with big bolts all around a beefy bulkhead.

I thought Caprice sailed very well in the light winds we had that

weekend. Tacked very smoothly through 90 to 100 degrees which is all

you can ever get with a low tech rig. Very smooth and quiet compared

to the sharpies I'm used to. It didn't seem at all sensitive to

fore-aft trim. In the light winds it went 5 knots on the GPS which is

certainly fast for the conditions.

Well, all in all I thought Caprice was everything I was hoping for..

Plans are $45.

Contents

Prototype News

Some of you may know that in addition to the one buck catalog which

now contains 20 "done" boats, I offer another catalog of 20 unbuilt

prototypes. The buck catalog has on its last page a list and brief

description of the boats currently in the Catalog of Prototypes.

That catalog also contains some articles that I wrote for Messing

About In Boats and Boatbuilder magazines. The Catalog of Prototypes

costs $3. The both together amount to 50 pages for $4, an offer you

may have seen in Woodenboat ads. Payment must be in US funds. The

banks here won't accept anything else. (I've got a little stash of

foreign currency that I can admire but not spend.) I'm way too

small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara

race. Shown here on its first sail except there was no wind.

Hopefully more later. (Not sure if a polytarp sail is suitable for

a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

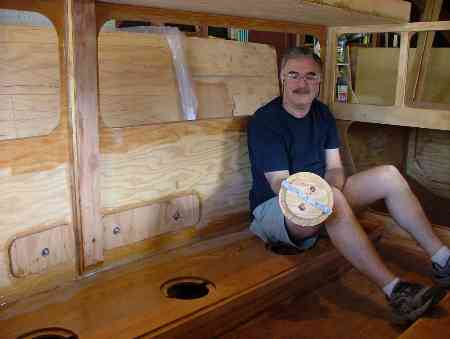

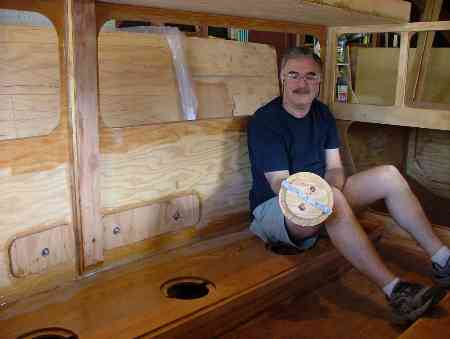

We have a Philsboat going together in California. You can see the

interior room in this 15' boat:

And here is another Philsboat in northern Illinois:

And here we have an LHF17 rowingboat. The boat is being assembled

now and the builder reports it to be at the limit of the taped seam

method because of the wicked twist in the garboard. That would be

true with any building method but perhaps the real Herreshoff

builders used steamed planks. The builder also doesn't like the

method of blending the ends of the planks into the stems (I copied

from Bolger) using putty and tape saying he would prefer

traditional rabated joint. Not a project for the first timer!

HOLY COW! A Jukebox2 takes shape in Minnesota. Unheated shop means

no work during the winter. Check out that building rig!

Contents

AN INDEX OF PAST ISSUES

BACK ISSUES LISTED

BY DATE

SOME LINKS

Mother of All Boat

Links

Cheap Pages

Duckworks

Magazine

The Boatbuilding

Community

Kilburn's Power

Skiff

Bruce Builds

Roar

Dave

Carnell

Rich builds

AF2

JB Builds

AF4

JB Builds

Sportdory

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)

Barry Builds

Toto

Table of Contents