My AF4 on a perfect day last summer.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(1jan06) This issue continues ballast calculations. The 15jan06 issue will rerun the essay about capsizing IMB.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

My AF4 on a perfect day last summer.

|

|

|

Ballast Calculations 3

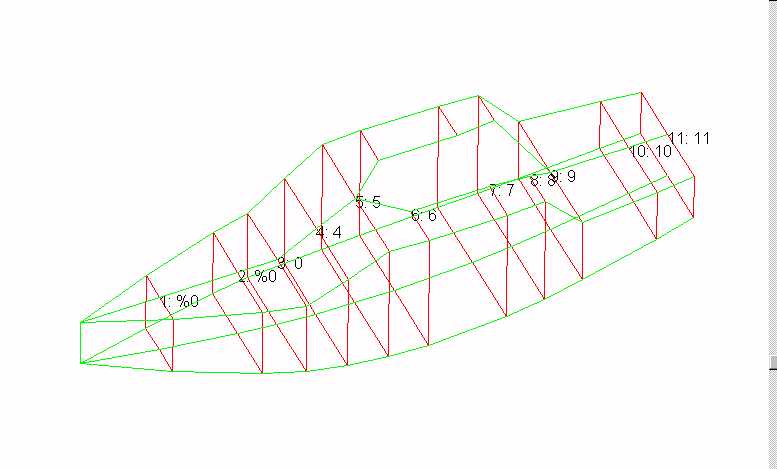

To recap a bit, two issues back we used this Hullforms model of a new design called Robbsboat...

...to solve the problem of finding a center of gravity for the hull that will allow "self righting".

The result was that if the cg were 17.5" above the base line (which passes through the very bottom of the boat) then the boat would self right from a 110 degree roll.

Then....last issue showed how to figure the amount of ballast required to get the center of gravity to the desired position. It ended up with 200 pounds bolted to the bottom of the main bulkheads, like this...

NOW...

FIRST....

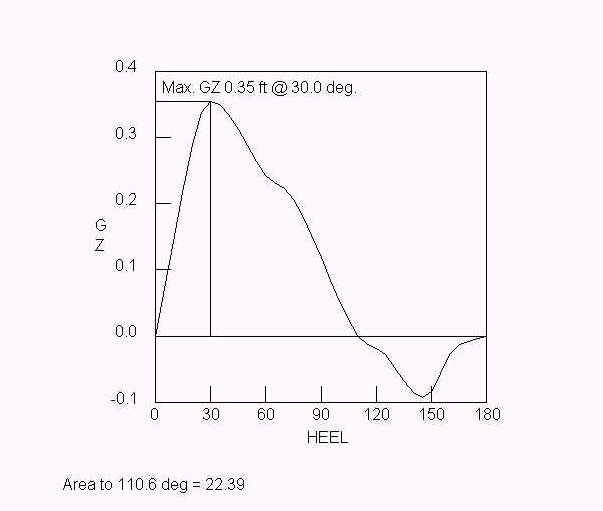

...it would be prudent to check one more thing. You might recall that the above righting moment curve is for Robbsboat at 1500 pounds and the cg at 17.5" above the bottom. But when we did the weight and balance tables we figured the Robbsboat when lightly loaded will weigh about 1000 pounds. So we'll run the hullforms one more time with the lightly loaded situation and make sure it is still OK. Here are the results of Robbsboat at 1000 pounds and cg at 17.5"...

It is more stable than before. No problem but now I'm thinking we ought to check it at 1800 pounds total, same cg location. We get this:

It is still good enough but it points out the importance of making sure that extra weight is stowed down low. If that is done then the cg location might drop below 17.5" and make it more stable yet.

NEXT...

We will look at the above charts and get an idea of the sail forces needed to actually capsize the boat. All of the three charts show that the righting moment peaks at about 25 to 35 degrees of heel. So if you were sailing this boat at say 20 degrees of heel you could expect it to take a bit more wind or sail power, it would heel more until it reached equilibrium again. But if you went past the peak, say about 30 degrees of heel, then it would continue to roll until something happened to ease the force on the sail. I suppose sailing at 30 degrees would be like riding a knife edge and a balancing act with quick reactions would be in order. (By the way, light flat boats will have the curve peak early, maybe at 15 degrees, and heavy deep sailers will peak later.)

Let's do a quick figure on how much the maximum righting moment is in foot pounds of torque. The charts show the "righting arm" in the form of Gz. That times the weight will give the righting moment. So for the 1000 pound case I see Gz = .46' so the righting moment is .46 x 1000 = 460 ft lbs. The 1500 pound case has a Gz =.35 so the max righting moment is 525 ft lbs. The 1800 pound case has a Gz = .32 for a max righting moment of 575 ft lbs. So the heavier she gets the more sail power it will take to upset her.

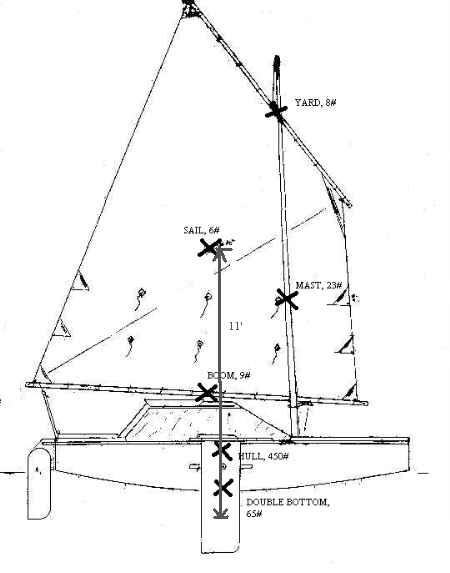

Let's use the light case to see how much sail power is needed to upset her. When at equilibrium a close hauled sailboat has almost all its sail power pushing to the side, only a small fraction is actually pushing the boat forward. That side force is balanced by the lateral area of the hull, in this case by the leeboard. On Robbsboat the center of the sail area and the center of the leeboard area are about 11 feet apart, like this.....

So for the light case of rm= 460 ft lbs a sail force of 460/11=42# will overpower the boat. For the heavy case it will take 575/11=52#.

Now, the forces on sails and wings have been studied by scientists for a long time. A "good" sail can generate about .005 x V x V pounds per square foot of sail where V is in knots. So in 5 knots of wind it would be .005 x 5 x 5 = .125 psf and at 10 knots it is .005 x 10 x 10 = .5 psf and at 15knots it is .005 x 15 x 15 = 1.12 psf. Since the wind speed is "squared" , that is multiplied by itself, in the equation you can see that a little more wind quickly gives a lot more force.

Anyway, Robbsboat is shown with 138 sq ft of sail cuz Robb want to go in light winds. So if 42 # of sail force will capsize the boat at light weight that is 42/138 = .3 psf on the sail. That corresponds with an 8 knot wind. Above that you will need to spill air by "feathering" the sail so it can't develop full power, or reef it down. A fellow might ask," I want to sail in 25 knots of wind reefed, how much sail can I carry?" So 25 knots wind will make about .005 x 25 x 25 = 3psf. And you can carry but 42/3 = 14 sq ft of sail (if the reefed sail is still efficient).

You can run the numbers for the other cases if you wish but Robbsboat has plenty of sail any way you look at it. And if the skipper slides over to the windward side of the hull the righting moment will increase and he can carry more sail. On the other hand if he slides to the leeward side of the hull he must carry less.

The above is the only way I know of to estimate "the right sail area". It isn't quick and will vary from condition to condition.

One last bit of info you can check with the righting moment charts is mast strength. Here again there are lots of variables. But if the boat flips at say 600 ft lbs then there is no point in designing a mast that is good for 6000 ft lbs since the boat will have capsized long ago.

A free standing mast like Robbsboat will have its maximum forces at the mast partner. Here the mast partner is 8' above the mast partner, so a 42# load on the sail will create a 42x8=336 ft lb torque on the mast at the partner. 336 ft lbs is 4000 in lb. Now, the elastic stress in a beam with a square cross section is 6 x m /(bxbxb) where m is the bending torque and b is the width of the mast at that point. On Robbsboat it is supposed to be 3" thick there. So the stress there is 6 x 4000 / (3x3x3) = 24000/27=900 psi. You can look up the breaking stress of wood in different handbooks but as I recall really high class perfect wood might break at 10,000 psi. I suppose the wood I buy is a lot less, especially when knots are taken into account, but it should still be way above 900 psi.

Could the mast be thinner? Sure if you have paid for perfect wood. But then it might be too limber and I think free standing masts are designed more for stiffness than strength. If the spars bend too easily the sail may not set well.

There might be another reason to go heavy with the mast. The above analysis is looking at lateral stability. Let's say you are running downwind under a real gale. Lateral stability is no problem. Now does the problem become one of sizing the mast for fore-aft stability, that is to say does the mast break before the boat pitchpoles end over end? I used to look at it that way but one day I told my theory to Phil Bolger who simply said, "Mast never fail that way. They always fail when close hauled." So I stopped thinking about it.

By the way, guyed masts are totally different animals than free standing masts. The wires pull down on the mast in tension. That creates compression in the mast and it will fail as a buckling column. I've seen it happen as I watched (to somebody else). Perhaps that is what Phil was thinking about.

Next time.....We capsize IMB.

AF4

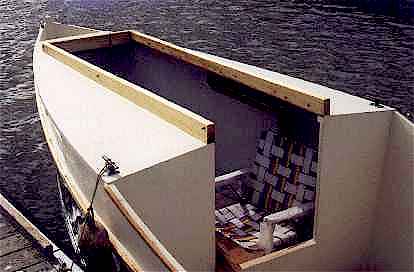

AF4, CUDDY POWER SKIFF, 18' X 5', 350 POUNDS EMPTY

AF4 is a simple low powered cuddy cruiser intended for protected waters. Kilburn Adams of St. Louis brought a boat similar in spirit to AF4 to our Midwest Messabouts and it was easy to see what a good idea this is. Kiburn's boat was a modified Sturdee Amesbury power dory with a small cuddy added and a new 4 stroke Yamaha 10. He thought the empty boat weighed about 600 pounds ready to go. It planed quite well with two men on board at about 13 knots. He made a 60 mile trip on the Mississippi (above the Alton dam where the current is small) burning about 4 gallons of fuel. It's quiet and cheap to operate. It's a good idea now that smaller 4 stroke motors are more common.

Here is an AF4 by Barry Targan. I think he is using a new 8 hp 4 cycle.

AF4 is supposed to do about the same job. Its simple hull shape won't handle rough going like the dory, but it's very easy to build and roomier. This boat has an open bow well for anchors and junk. The cabin is 8' long and 3' deep and 4' wide for minimal camping. It should be comfy for one and snug for two. it has a slot top to allow stand up boating in good weather. You cover it with a snap on fabric piece in the rain and cold. The cockpit is a full 6' long and 4' wide and totally open. You could lounge there too with a folding chaise. Aft of the cockpit is a draining motor well which will take the standard 6 gallon fuel tank and then some.

For power I used to say 10 horsepower maximum but now I would say 15 or 20. My boat has gained gear and weight over the past years and is more comfortable with the extra power. This past year I picked up a early 60's Johnson 20 at an antique outboard meet where no one is interested in such things because they are so common. The owner had $80 marked on the tag and I took a long look at it. Guru Max said to look over the lower unit really hard before buying anything and sure enough there was a crack in the casting below the prop, a sure sign that the unit leaked water and froze hard during the winter. So I told the owner I wasn't interested and that I didn't need another motor anyway. I asked him if it ran. "Sputters and leaks fuel out of the carb," says he. "Make me an offer," says he, "I don't want to take it home again." "I don't want to take it home either," says I. "$30," says he. I paid him and took it home. A mighty rap on the carb float bowl with the handle of a big screwdriver fixed the leak no doubt caused by a sticking float. A new spark plug fixed the sputtering and she was quickly purring in the test tank. I patched the crack in the lower unit casting with epoxy but she still leaked like crazy if the water level was above the prop so I'm convinced the seals are shot in the top of the casting. I swapped the drive unit from the Buccaneer 12 that I got two years ago (never did get that one to run on two cylinders) and was off to the lake. Put about ten hours on it and it ran perfectly the whole time. Slightly faster than the 15, burns more fuel and is noisier. At the end of the season I decided the 15 was a better all around motor in my case where I am almost always solo so I reinstalled the 15. A light AF4 planes with an old Sears 7-1/2 horse (single cylinder, air cooled, for $50 at a yard sale) as you can see here:

Here is John Bell & co. in his AF4. I think John is using a 20 hp four stroke having tested the boat first with 25 hp and found it too much.

Here is one by Rhett Davis at the last Rend Lake meet.

And here is another by the motor guru Max W at sunrise during our last campout.

Bayard Cook built this delux AF4 in Florida:

AF4 uses the simplest nail and glue construction. It takes five sheets of 1/4" plywood and four sheets of 1/2" plywood.

There is also a shorter 15' version called AF4Breve, the prototype shown here built by Bruce Given.

Plans for either AF4 or AF4Breve are $30.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

The out West Picara is I am told done to the point of using it as a powerboat:

The down South Picara is more or less complete now. Should have an updated photo soon.

This long and lean project is a 19' version of Toon2. Shown here on its first sail in very light winds. We will wait a bit longer to get a sailing report in stronger winds.

A Vector builder is keeping a website of the project at http://www.geocities.com/michsand@sbcglobal.net/ and here is a photo of his boat on its first sail, just before the storm hit. I also have photos of a Vector completed by Pete Mohylsky in Florida. Hopefully a report soon:

Here is a Musicbox2 I heard about through the grapevine.

We have a Philsboat going together in California:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)