Chris Crandall's prototype Harmonica shoving off. Looks like five men in a 13' boat.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15jan07) This issue will present some letters I have received involving the power guestimate articles. The 1February issue will rerun the IMB capsize article.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Chris Crandall's prototype Harmonica shoving off. Looks like five men in a 13' boat.

|

|

|

Figuring Power 3

...LETTERS, WE GET LETTERS...

I have received several mails about the power topic I've been trying to figure out for the past few issues.

FIRST, FROM JOHN KOHNEN,

who does the Mother of All Boat Links. He adds a little history about the Homelite:

"Jim-

That Homelite/Bearcat engine is an interesting one. It started out life as a Crosley automobile engine in the late '40s. It was a beautiful little engine, built like a watch, and was also marinized for use in boats. My first boat was a 14' runabout powered by a Crosley engine, with a V-belt V-drive and no clutch or reverse. It was fast! :o) In the '50s a company called Fageol started making outboards using a Crosley engine turned on end. This was the direct ancestor of the Homelite/Bearcat. Homelite bought Fageol, or otherwise acquired the right to build the engines, and then Homelite sold their outboard division to Fisher Pierce. Here's a history of Crosley engines and their derivatives. The Homelite/Bearcats are on the "Big Block Years" page, Fageol is on the "Post Crosley" page:

This doesn't have much to do with the present subject but the history of the Crosley engine is fastinating in general. When I looked at the above website I recalled right away an article I saw in my youth in Hot Rod Magazine where a midget racer was running a souped up Crosely engine. The neat thing about the first Crosleys was that they were made from sheet metal brazed together! Thus they weighed maybe half as much as a cast iron engine and thus the interest for the racers.

NEXT, FROM JOHN BELL,

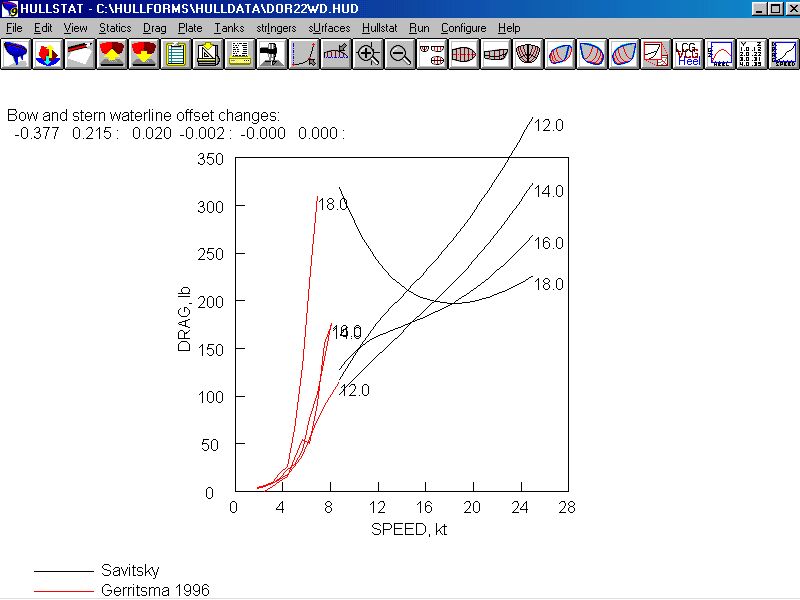

Who built his AF4 Mr. Moon a few years ago and ran it with modern motors. You might recall for the Dorado variants I was looking at with Hullform this plot of drag vs speed for various trim situations:

This shows the boat using a lot less drag at higher speeds if the weight is trimmed way aft. I said in my article that I had never noticed the effect on my AF4. But John wrote:

"My observation on my AF4 was that if you wanted to go fastest was that you needed to get as much weight as far aft as you could. At WOT (15HP Merc 4S, 9x9 prop) it would go 20 mph (GPS) if I stood at the companionway and accelerate 22.5 mph if I sat on the bulkhead at the aft end of the cockpit. I think the difference was getting more boat out of the water which reduced drag. Of course, these kind of speeds were only possible in early morning flat water conditions. The boat (and her skipper) was much happier at 12-14 mph.

Looking at your graphs of speed versus power while remembering my AF4, I am reminded of what a pig my current boat is. It's a 27' pontoon with a 115HP 2S Merc on the transom. At WOT with a clean bottom and a light load, it will only go 22-24 mph whileburning ~13 gallons per hour! (gasp!) "

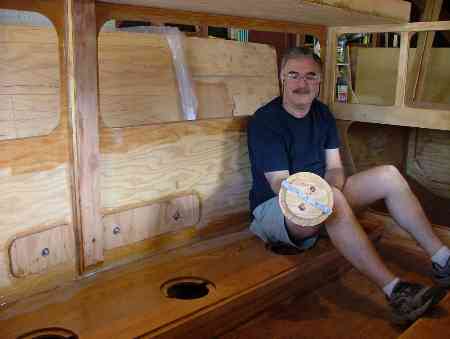

The above photo shows John's AF4. Clearly I did not run my AF4 in the tests fast enough to notice the effect of the trim. So I guess the Hullform professor can score himself a few more points. We haven't caught him lying yet.

LAST, SOME LETTERS FROM ROBERT CORNWELL....

... who may be the Eistein I was looking for. You may recall my Thrustometer tests with AF4 a few years ago showed that the predicted Hullform drag for my AF4 was close to what I was measuring. But it appeared that only about a third of the rated horsepower was driving the boat. Where did the lost power go?? Robert wrote:

"I really enjoyed reading your article. And your thrust measuring machine reminds me of something 'Myth Busters(r)" might come up with. The only quarrel I have is over the alleged discrepancy's. I don't believe there is one.

First off. Most gasoline engines actually put out only about 85% of their 'advertised' HP. And that is because of how their HP is measured. It seems that They give the engine in question a lot of 'life support' when they test it. Cooling water is delivered free as well as the spark energy, all of which the engine has to provide for itself in real life.

Also. There is the issue of 'Peak HP' vs 'Intermittent' vs 'Continuous' . 'Peak' is what is on the brochure. Most engines are set up to never produce 'Peak'. And for good reason. They will blow apart in seconds should they be run that way. So now all you have to work with is 'Intermittent' and 'Continuous'. 'Intermittent' is what you actually get when you fire wall the throttle. It is roughly 80% of 'Peak'. Even running the engine at this power setting limits its life. This is OK to use when getting your car out into to traffic or your runabout up on a plane. Most of the time, though, your engine is running somewhere in between zero and 'Intermittent'. Boat engines as well as airplane engines are usually designed to run comfortably at rates close to 'Intermittent'. That's why they have such short TBO ( To Be Overhauled) times. A tug boat engine (with its massive weight to HP ratio), for example, can be run tens of thousands of hours as opposed to just a one or two thousand hours for the engine under the cowl or under the hood.

The final factor to figure is the horrendous inefficiency of propellers. If your outboard prop is 55% efficient, you should kiss its designer. This is because only three quarters of the prop is actually pushing the water aft. The other twenty five percent is simply stirring it up. This is an unfortunate fact of life that seems like it simply can't be helped.

Now let's take the three new factors I just brought in and multiply them out. 'Peak' (85%) * Intermittent (80%) * prop efficiency (55%) = 37.5%.

Comes pretty close to your test results already. Now factor in wear and tear on the engine and maybe a chip or two out of the prop as well as a possible mismatch between propeller, load, and speed, and we can easily whittle this down to less than 33.3%, which I believe is even closer to your test results.

That Savinski fellow was pretty bright, wasn't he. "

Savinski is the guy Hullform is using to predict hull drag when the boat is on plane. Here is the chart Robert refers to:

I began to question him about the poor prop efficiency since we had measured prop "slips" that were pretty good at cruise speed. He straightened me out:

"Propeller slip has is no where near the whole story on propeller effiency. Think of a propeller as a rotating wing. Your slip ratio only measures the 'lift' of the rotating wing. It does not measure the drag at all. This is a very important distinction. On airplanes, 'lift' is measured in proportion to drag. A crude, barnyard test of this is puting a glider airframe on this wing and heaving it off the hayloft and seeing at what angle it glides at as well as how far it goes. I can think of no such test for a propeller blade. Most of the boat design liturature I have read gives the rule of thumb of needing two ACTUAL HP per every 'Estimated HP' (the actual force needed to move the boat at its design speed). And this is for inboards with (real world) perfect prop matches."

Just to sure I questioned him again on this topic and, yes, if you calculate with Hullform that your hull drag and speed add up to X horsepower, then you must mount at least 2X horsepower to have a chance of going that fast. And that would be with the very best and not even an outboard. As he said it:

"You are right. I did mean that that you need (2) SHP (Shaft Horse Power) for every (1) EHP (Estimated Horse Power). And that is under ideal real world conditions, or, in other words, as good as it gets."

I ask Robert about my pet theory that the lower unit drag, which my tests don't measure, was a culprit. He replied:

"As for the drag of the lower unit, that should be relatively easy to measure. Just take the prop off one of your outboards and mount it on the transom. Set up a scale arrangement similer to the one you used to measure thrust, then drag that propless unit through the water. I think you will be dismayed by how little drag it produces. That being said, the big joker in the pack is the propeller interaction with the slip stream from the lower unit. That, I'm at a loss to measure."

Getting complicated, huh? One of the funny things about engineering is the idea of "measure with a micrometer and cut with an axe." Which is to say you can analyze things to death but it takes real life to give real answers. Robert added:

"I think this all gets back to design being more of an art than a science. It seems to me that 'rules of thumb' tend to be at least as accurate as intricate formulas. I believe the reason for this that we can never even come close to getting a grip on all the dozens of factors, known and unknown, that we are actually dealing with. All have to be taken into account before a truly straight 'scientific' analysis is truly possible. The beauty of 'rules of thumb' is that they are usually based on actual past experience. The only danger with them is that they may not be updated frequently enough due to advances in technology."

AMEN to that! Without any prompting from me Robert added:

"It has long been a dream of power boat designers to come up with a hull form that planes well but runs efficiently at displacement speeds as well. This is such an old dream, it might as well be the holy grail of powerboat design. The most traditional way of handling this is to make either a shallow displacement hull with a relatively long, flat, but not neccessarily level section aft. or to make an unusually narrow planing hull, so that the full depth transom is as small as possible (Bolger even designed a sailboat like this. I believe he called it SPLINTER). Both approaches are only partly effective. It seems that your af4 design uses the former approach, which I do think is better. I would much rather plane slowly at, say, 10 to 15 kts than wallow and suck gas while at displacement speeds."

Those of you who have written to me asking for the mythical planing motor/sailer know I have never come up with the answer. I don't know how to do it simply and I don't know if anyone does.

Finally Robert gave credit where credit is due saying:

"By the way, you can thank Cy Hamlin for the engine imfo I gave you. I learned almost all of it from him. It is in his excellent book "THE PRELIMINARY DESIGN OF BOATS AND SHIPS""

So there are lots of Einsteins out there. I suspected this info has been around since the first tow tank, I just couldn't find it. I guess the motor and prop makers don't want such knowledge up front.

NEXT TIME...

...we'll capsize that IMB again.

AF4

AF4, CUDDY POWER SKIFF, 18' X 5', 350 POUNDS EMPTY

AF4 is a simple low powered cuddy cruiser intended for protected waters. Kilburn Adams of St. Louis brought a boat similar in spirit to AF4 to our Midwest Messabouts and it was easy to see what a good idea this is. Kiburn's boat was a modified Sturdee Amesbury power dory with a small cuddy added and a new 4 stroke Yamaha 10. He thought the empty boat weighed about 600 pounds ready to go. It planed quite well with two men on board at about 13 knots. He made a 60 mile trip on the Mississippi (above the Alton dam where the current is small) burning about 4 gallons of fuel. It's quiet and cheap to operate. It's a good idea now that smaller 4 stroke motors are more common.

Here is an AF4 by Barry Targan. I think he is using a new 8 hp 4 cycle.

AF4 is supposed to do about the same job. Its simple hull shape won't handle rough going like the dory, but it's very easy to build and roomier. This boat has an open bow well for anchors and junk. The cabin is 8' long and 3' deep and 4' wide for minimal camping. It should be comfy for one and snug for two. it has a slot top to allow stand up boating in good weather. You cover it with a snap on fabric piece in the rain and cold. The cockpit is a full 6' long and 4' wide and totally open. You could lounge there too with a folding chaise. Aft of the cockpit is a draining motor well which will take the standard 6 gallon fuel tank and then some.

For power I used to say 10 horsepower maximum but now I would say 15 or 20. My boat has gained gear and weight over the past years and is more comfortable with the extra power. This past year I picked up a early 60's Johnson 20 at an antique outboard meet where no one is interested in such things because they are so common. The owner had $80 marked on the tag and I took a long look at it. Guru Max said to look over the lower unit really hard before buying anything and sure enough there was a crack in the casting below the prop, a sure sign that the unit leaked water and froze hard during the winter. So I told the owner I wasn't interested and that I didn't need another motor anyway. I asked him if it ran. "Sputters and leaks fuel out of the carb," says he. "Make me an offer," says he, "I don't want to take it home again." "I don't want to take it home either," says I. "$30," says he. I paid him and took it home. A mighty rap on the carb float bowl with the handle of a big screwdriver fixed the leak no doubt caused by a sticking float. A new spark plug fixed the sputtering and she was quickly purring in the test tank. I patched the crack in the lower unit casting with epoxy but she still leaked like crazy if the water level was above the prop so I'm convinced the seals are shot in the top of the casting. I swapped the drive unit from the Buccaneer 12 that I got two years ago (never did get that one to run on two cylinders) and was off to the lake. Put about ten hours on it and it ran perfectly the whole time. Slightly faster than the 15, burns more fuel and is noisier. At the end of the season I decided the 15 was a better all around motor in my case where I am almost always solo so I reinstalled the 15. A light AF4 planes with an old Sears 7-1/2 horse (single cylinder, air cooled, for $50 at a yard sale) as you can see here:

Here is John Bell & co. in his AF4. I think John is using a 20 hp four stroke having tested the boat first with 25 hp and found it too much.

Here is one by Rhett Davis at the last Rend Lake meet.

And here is another by the motor guru Max W at sunrise during our last campout.

Bayard Cook built this delux AF4 in Florida:

AF4 uses the simplest nail and glue construction. It takes five sheets of 1/4" plywood and four sheets of 1/2" plywood.

There is also a shorter 15' version called AF4Breve, the prototype shown here built by Bruce Given.

Plans for either AF4 or AF4Breve are $30.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

We have a Philsboat going together in California. You can see the interior room in this 15' boat:

And here is another Philsboat in northern Illinois:

HOLY COW! A Jukebox2 takes shape in Minnesota. Unheated shop means no work during the winter. Check out that building rig!

And the Vole in New York. Going very quickly but most likely there will be little more done during the cold winter.

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)