Still another RB42, this one by John Gayton and stretched out to take four oarsmen and a steersman. Australia, of course (where else?).

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Sep08)This issue will will discuss what rainwater can do to your wooden boat. The 1 October issue will repeat the bevels essay.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

THE 17 ANNUAL INDIANA MESSABOUT...

... will take place at Lake Monroe near Bloomington, Indiana in late September. John McDaniel writes: "Go to http://pwp.att.net/p/pwp-mwmess for more information. Susan and I plan to put BANTY in the water on Friday and sleep aboard a couple of nights. Come join us..... well, bring you own boat or tent... BANTY only sleeps two. The Saturday pitch-in dinner is always good and the campfire chat is even better. This year we'll have a representative from Gougeon Brothers, Inc., manufacturer of WEST SYSTEMŽ products present on Saturday to discuss epoxy and epoxy products. Sunday afternoon we're hosting anyone interested at the McDaniel-Shanklin Donkey Farm & Boat Emporium (Columbus, IN). You can check progress (or lack thereof) on our 48' sailboat and enjoy a burger or hotdog."

Rainwater Damage

HISTORY...So there I was working one summer at a big sailboat marina and we had to move a few boats around. They had been on the parking lot for a few years, maybe we didn't even know who owned them. One was a big Thunderbird, very unusual in the Midwest. Propped up on stilts with its keel in the ground. The tractor couldn't budge it. A quick check showed it was full of rainwater maybe 3' deep inside. A big sump pump dropped down inside ran for a few hours to get most of it out. I don't recall what damage was done on that one but I think it may have survived.

But the one beside it sticks in my memory. It was a very well made British twin keeler made meticulously out of plywood and beveled sticks of all sorts. How did that thing end up in Illinois?? This one was on a trailer and also full of water. Pumped it out. Hooked up the tractor to the trailer and gave it a jolt. Immediately the twin keels and inside ballast fell onto the hardtop! The entire bottom fell out. It was off to the dump (after we stripped it of its fine English hardware).

HERE'S ANOTHER...

A local small trailer sailer left outside for the winter. Made of lauan underlayment plywood with an outer coating of fiberglass. Looked fine at first glance. Cockpit had a drain so it was dry. But the two end chambers had leaked during the winter and filled with water. Again no clues from the outside but looking under the hatches gave me a start. Half full of rainwater, the inside plies had totally come apart and pieces were floating around in the water. Here only that thin outer ply and its glass remained.

A PERSONAL NOTE...

My second ever boat was a Bolger Jinni. Essentially a 15' sharpie yawl with the forward and aft buoyancy/storage boxes that I still prefer. Big center cockpit. This was the first boat I had built from real lumberyard materials and I had used Weldwood water mix glue as was very common in 1980. I took great care of it in its first few years, stored indoors. But as more boats came along it eventually got stored outside on its trailer. I put a tarp over it but that was limited, especially I suppose in the winter. So it sat out there for a year or so, often with inches of rainwater inside the cockpit. Eventually I noticed the inner chine logs were getting soft and then became a refuge of small vegitation. Chipping away at the rot or whatever I found that the Weldwood was gone in the areas that were soaked for months. The nails still held it together and the spash of fiberglass over the chines kept the water out. The AC exterior plywood was actually pretty good. It was the pine chine logs and disappearing glue that caused concern. What to do??

That must have been about 1990 and I had decided to start designing my own boats. I had the Birdwatcher back then and thought the slot top had possibilities way beyond Birdwatcher. Why not test it on a different layout, say a cuddy cabin boat? Why not convert the Jinni into a cuddy cabin boat? So I chipped out those rotten chine logs, put in new bulkheads and formed a cuddy cabin just small enough to lie down in. I replaced the chine logs with taped seam fillets and all was well. And by now I knew that a boat stored outside needed drain holes cut in its bottom to drain that rainwater, several, anyplace water wanted to collect. Don't forget to put them back in before you go boating.

And what if one of those plugs should pop out while you are afloat? I learned that answer first hand one time while sailing my Piccup Pram. It was a 1" drain on the forward edge of the cockpit. I was a mile from shore when I kicked it with my foot and out it popped. Well, if you have seen disaster films you know water shoots through the portholes of a stricken ship like a fire hose! But not so on the Piccup. It was sort of like tipping over a thermos, a slow gurgle. I pushed the plug back in (the plugs install from the inside not like a transom drain on the outside) and tightened it. I suppose there was a cup or two of leakage. Disaster over!

BACK TO THE JINNI....

Eventually my boats multiplied and I needed the space and trailer for my AF4. How to get rid of the Jinni. Pretty simple it turned out. A sledge hammer and a saber saw quickly reduced it to a few big chunks which I burned when the neighbors weren't looking. The whole episode took an hour or two and it was gone without a trace except for a burnt spot on the lawn with some charred screws and nails.

SO NOW ON TO THE AF4...

Had I learned any lessons? Well one thing I was careful to do was to put a fillet of epoxy putty around the inside joint where the bottom meets the sides and bulkheads. I have an idea that water inside the boat will try to wick under that joint and up into the plywood sides. When I rebottomed the boat after ten years the side joints were totally tight, the chine logs (external) solid. I had a drain in the center of the cockpit just behind the main bulkhead. When the boat is stored on its trailer water tends to gather there but I found mine likes to gather in the port corner of that bulkhead so I still had sometimes a bit of water there. It didn't cause any rot but was messy. When I put the new bottom on last winter I put the new drain hole in that corner. It wouldn't be a big deal to put lots of drains in. Oddly enough, one area that did rot was in the wood right around the old drain. Perhaps it was always wet there.

So where did my AF4 rot to finally cause needing a new bottom. The first area was the stern, rotting from the inside. In spite of our tourism bureau showing Illinois waters as crystal blue, they are actually muddy brown. About eight years of muddy water gathering in the stern while trailering (she trailers stern down a bit behind my old truck) resulted in a quarter inch or so of mud that didn't dry out quickly at all. Poor access to that area under the motor well kept the mud in place. Always damp, it rotted. When I rebuilt it I opened up the stern with much larger access holes and I can get to anywhere under there now easily.

I suppose that brings up the question. "I want to keep water out of my storage areas. How do I do it?" Well, from what I have seen water will get into anywhere. So make your volumes as tight as possible but always have a plan to air them out when the boat is stored. Personaly I think that is the big dare with water ballast in a wooden boat. The volume is supposed to hold water but I still think in storage that volume needs to be drained and open to the air to give it a chance to dry. With the few water ballast boats that have been built to my designs so far no one has complained of rotting.

WHAT ABOUT EPOXY COATING...

...you ask. Epoxy is not totally waterproof, it is just more waterproof than other coatings. Dave Carnell told me once about his Bolger Zepher which was given three coats of epoxy, like paint, as a water barrier. He weighed the boat right after he finished it. Then left it outside at his dock all year. I think I recall he said it doubled its weight in absorbed water. Then he put it under shelter for weeks and it returned to its original weight. Clearly the epoxy did not keep the water out of the wood. But remember the boat was kept in the water and allowed to catch rainwater for months at a time. So the idea that epoxy is "waterproof" doesn't seem to be true.

But many people swear by it and I think the reason is that for a trailer boat, which will not be immersed in water, the epoxy effectively keeps the water out. The boat might experience long periods of rain and dampness that will penetrate paint and polyester resin, but not get through the epoxy coating before the sun finally breaks out. But if the boat is allowed to fill with rainwater for long periods I suppose the water will eventually soak through.

LIFE AND DEATH OF A(n) HARMONICA....

Actually the jolt that got me to thinking about this subject was a letter from Chris Crandall who had built the prototype Harmonica years back. He brought it to our messabout when the paint was still wet. Then it had maybe a 2 hp Tanaka that I think made 3 hp worth of noise. Later replaced with a Honda 5 I think. Anyway, he had a lot of fun with it which is whole idea. (As I recall he built it inside his rec room requiring disassembly of a wall to remove later.)

There followed years of family fun

Followed by a last trip...

Followed by open storage...

Followed by rot, sawzal, and disposal...

THE END!

Mayfly14

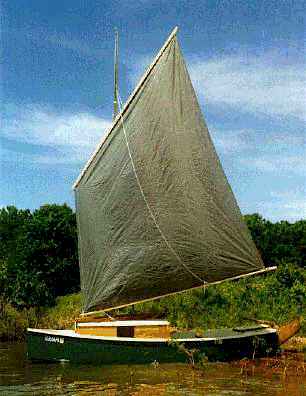

MAYFLY14, ROW/SAIL SKIFF, 14' X 4', 150 POUNDS EMPTY

Mayfly14 is a straight forward flat bottomed plywood skiff for sailing and rowing. She's easy to build because her planks have no twists. That means that the chine log and wale bevels are constant for all practical purposes and can be presawn before assembly. The construction is of the simplest nail and glue variety with no building jigs or lofting required - an "instant" boat. The prototype was built by Garth Battista and kids in Halcottsville, NY.

I think this boat is about the right size for a lot of folks, although I might argue that it is too heavy to cartop with comfort and once you decide to trailer a boat you might as well go to a sixteen footer. Mayfly14 will take two adults easily and yet still be a wonderful solo boat.

The sail rig is a balanced lug which is easy to build and stow. I recommend that my customers sew their own sails either from common polytarp (as Garth did in the boat shown above) or real Dacron sailcloth. The plans show instructions for sewing in real sailcloth. You need a sewing machine that sews zigzag stitches and cheap home machines are usually good at that. I don't claim to be the world's best sailmaker but it is not majic. I can do it and so can you. The clothes you are wearing are ten times more complex than a small sail. There are a few rules to follow and I give an essay on that with each set of sailboat plans. In fact I suggest you sew your sails before you build your hull. Both sail and hull require about the same work space. Sew the sail first, roll it up, stuff it in a closet, and now your workspace is ready for your hull. Getting the sail done can get you over a big mental hurdle.

Garth's friend Ari made this Mayfly14 shown in shallow water at Long Island Sound:

Here is another by Don and Tom Burton in Illinois:

And another by John Dominique in Louisiana...

Mayfly14 needs three sheets of 1/4" plywood and two sheets of 1/2" plywood.

Mayfly14 plans are $30. But, the Mayfly14 plans are shown complete in reduced size in my book available from Duckworksmagazine.com along with Garth's blow-by-blow assembly photos plus a huge amount of other stuff.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the "ketchooner" rig, featuring his own polytarp sails, that is shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Batista's of www.breakawaybooks.com, printer of my book and Max's book and many other fine sports books. Boat is done, shown here off Cape Cod with mothership Cormorant in background, Garth's girls are one year older. Beautiful job! I think Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat.

And the Leinweber's make another prototype! This one by Sandra, an Imresboat shown here on its first outing. They are taking it on a "cruise" so more about it later.

And a new Down Under Blobster, now upside down....

A view of the Caroline prototype showing a lot of the inside, crew on fore deck. Beautiful color:

I gotta tell you that on the Caroline bilge panels I made an error in layout and they are about 1" too narrow in places on the prototype plans. I have them corrected but it always pays, even with a proven design, to cut those oversized and check for fit before final cutting.

And the Raider of Norm Wolfe did indeed make it to the Finnish Raid. I'll bet the paint was still wet.

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)