Ron Keats goes acruisin' in his new Dockbox. Wonderful job!

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Dec09)This issue will close out the new design ballast essay. The 1 January issue will rerun a knockdown essay.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

|

Left:

Ron Keats goes acruisin' in his new Dockbox. Wonderful job!

|

|

|

Ballast Again 3

NOW WHERE WAS I?????

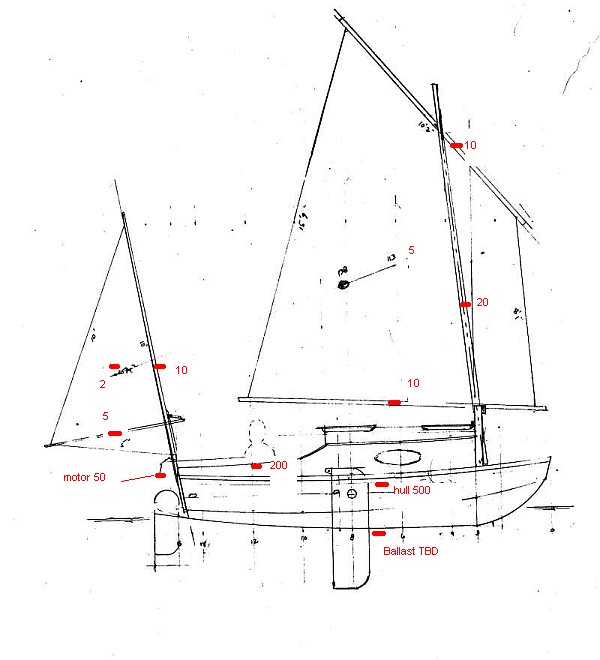

...In the 15nov09 issue we tried to work out the ballast details for the little cruiser.

The idea was to get the cg down to 19" above the bottom, which is where the Hullform model predicted that shape hull would self right when rolled up to 90 degrees (beyond that and it will most likely lay on its side somewhat mast down as long as the spars are buoyant wood). Crashing through the numbers revealed that 380 pounds of ballast just below the bottom was needed to get that cg position with a crew of one on board, and 280 pounds needed if there were no crew on board, ie, the skipper has abandoned ship, the ship self rights when he does so and he has to regain the ship somehow. The skipper who commissioned the boat wants that second option. So there we are....almost.

MORE DETAILS....

As Harry, the weights guru, told me back at the missile factory, "We always knew what the thing will weigh, we just don't know where the weight is yet." In particular my guess that the bare hull structure would weigh 500 pounds and that its cg would be 20" above the base can be refined now.

At this point we now know the bare hull will need six sheets of 1/4" plywood (about 150 #), five sheets of 3/8" plywood (about 170 pounds) and three sheets of 1/2" plywood (about 150 pounds). The total ply weight is about 470 pounds and I think that should be about the weight of the hull structure so the 500 pound estimate seems secure. But a third of that weight is in the bottom and my assumption that its cg will be 20" above the base can be refined to 18". A small bit of advantage perhaps. So the resulting total cg is a bit lower than I first assumed and crunching through the ballast numbers again shows 230 pounds of lead should suffice instead of 280 pounds.

While we're on this topic I will say that the bottom is intended to be two laminations of 1/2" plywood. Any extra thickness down there is almost as good as lead as far as the total cg is concerned. I would very seriously consider making the bottom three plies thick, a full 1-1/2", and then putting the lead requirement down to 200 pounds. I think I will do that. With a bottom as bulletproof as that we can I think bolt the lead straight through the bottom, no extra structure required.

NOW, ON TO THAT LEAD....

I have cast some lead but always in smaller castings. In particular I did a long time ago a Micro ballast. That was supposed to be one 425 pound casting but Bolger's structure clearly allowed for it to be done in small sections glued and nailed to the keel structure which has plywood facings. I think my lead "bricks" were about 40 pounds each and that was easily done solo. So we can do that again with this one.

Lead weighs .4 pounds per cubic inch so 200 pounds of it would be 500 cubic inches. Lets do that in eight 25 pound "bricks". So we want 62 cubic inches per brick. So if you make a mold to cast a brick that is 1.5" thick, 3.5" wide, and 12" long, you get the 25 pound brick. Do that eight times. Each brick will be secured along the outside bottom centerline more or less as a "shoe" to total 8' long. They won't be fastened to each other since we don't need strength in the lead because we have a really thick bottom. Let's bed each brick to the bottom with latex caulk and fasten with a 1/4" stainless bolt at each end, total of 16 required. Bolt head on the inside of the hull, also sealed over with say rtv, and nut end on the outside in a recessed hole in the lead brick, also all sealed over with rtv. The idea is to allow for future removal. It should work and be done with some ease by a solo builder. Last I looked 200 pounds of scrap lead would cost about $100 but its daily value can fluctuate wildly.

NEXT TO GLANCE A RIGHTING MOMENT DIAGRAM...

Hullform will calculate righting moment diagrams in a jiffy. These are nearly impossible to do by hand in a normal lifetime so small boats always did without them until the PC was invented.

Anyway, I ran the Hullform program for this shape with a total weight of 1000 pounds (probably the minimum this boat will sail at) and the 19" cg location. Here is a graph of the results...

Hmmmmm... Interesting. This is actually a composite of two Hullform models. The first is the full hull model and the second model has a cut down stern that is supposed to simulate flooding of the cockpit deck, but not under it. I assumed the cockpit would flood at about 60 degrees so don't take that part of the curve too seriously.

Well, there is nothing kinky about it. I don't see any sudden swings that you would see with a light flat bottomed boat that will capsize all of a sudden. This one settles in at about 700 ft-lbs. By the time it starts to fall off at around 60 degrees the cockpit would be flooding and I would hope the skipper is getting scared enough by then to release the sheets if he can get to them. Well, so far so good.

NOW FOR A LOOK AT THE SAIL AREA...

The above curve is for what is probably the lightest sailing weight for this boat, that is with a single skipper and almost no gear. If she weighs more you can multiply those righting moments by the ratio of the higher weight, so if she weighs 1500 pounds then the max righting moment would be about 1000 ft-lbs. But don't forget eventually at about 90 degrees the righting moment goes to zero and any ratio times zero is still zero.

The righting moment is resisting the overturning moment produced by the sail's sideways force and by the force on the leeboard that is opposing the sail's sideways force. When a boat is close hauled almost all of the sail's force is really to the side and I will assume that for now to make like simpler here. The center of the sail area on this boat is about 12' above the center of the leeboard area so to make a 700 ft-lb overturning moment the sail's force would be just 58 pounds. Now the question is "How much wind will produce 58 pounds on the 113 sq ft main sail?"

OK, in a general way the force of the air on a sail or wing or whatever is F= .0034 x S x C x V x V where S is the "area" in square feet, C is a coefficient related to foil shape etc that we need to look up from test data, and V is the wind speed in knots. So this mainsail has an area of 113 sq ft, and the C is usually about 1.5 when the wind is fully applied on a typical good sail. It works out that V would be equal to 10 knots. We would expect the boat to be overpowered if the wind exceeded 10 knots. That is not very windy but lug sails usually reef well so the skipper will need to keep an eye out. On the other hand in order to sail well in light winds you need to have a lot of square feet up there. As an aside I should say that you find as you get elderly that a small sail area to handle higher winds and a good motor to handle lower winds is a very good combination.

WELL, WE'RE ALMOST DONE....

One last quicky check we can make now is to get a wag at the stress in the mast. Most masts really are sized by how much they bend more than their strength but once we have gone this far the strength check is pretty simple.

The weak point for the mast is bound to be right where the mast meets the mast partner because that is where the bending is the highest. I'm talking about free standing masts like this one, masts that are supported by guy wires are a whole different animal.

If you know your boat is going to capsize if the force on its sail exceeds 60 pounds then you can start with that number I think as a check. After all, if the sail force exceeds that then she goes over and you have an entirely different problem. (Once I mentioned to Phil Bolger that the boat is a lot more stable in pitch so a boat getting blown downwind could have a much higher mast load than one that is close hauled. Phil thought about that for a few seconds and simply responded," Yes, that makes sense. But sailboat masts always fail when close hauled." I've always accepted that and only make the close hauled check.)

Anyway, this boat has its sail area centered about 7' above the mast partner. So the actual bending moment of the mast at the critical point is about 60 x 7 = 420 ft-lbs at the capsize point (we need to convert that to 5000 inch pounds to be consistant in future calculations). The elastic bending stress in the mast is then easily calculated. The proposed mast there would be 3" square. The maximum fiber stress in that square section would be stress=6xM/(txtxt) where M is the bending moment and t is the mast thickness. It works out to be 6 x 5000/(3x3x3) =1100 psi. Perfect Sitka Spruce might handle up to 10000 psi but probably not pine from Lowes. So the stress sounds low but there are many warnings. For one the righting moment was taken at the lightest boat weight with no one hiking out. And this is a static analysis. A dynamic analysis with hull rolling etc might run the numbers way up, but I'm too stupid to do a dynamic analysis. Like the great engineers of olden days I'm satisfied with static numbers and a big margin of safety.

Raider

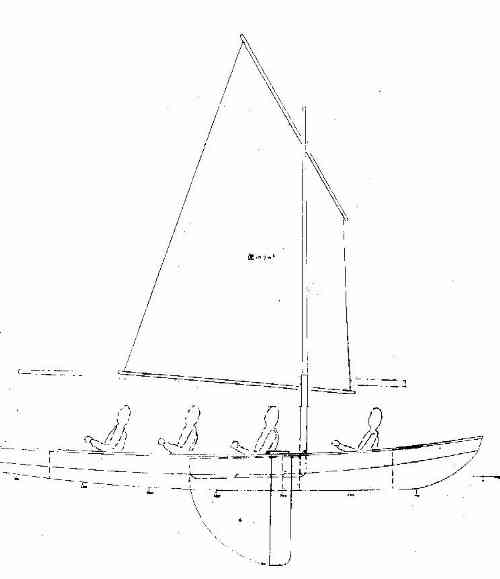

RAIDER, ROW/SAIL BOAT, 24' X 6', 500 POUNDS EMPTY

Norm Wolfe built his Normsboat to my design so we were acquainted. He visits the Baltic countries regularly and had participated in a "Raid" in Finland and was going to make it a regular thing, maybe with his own boat. A Raid is a pseudo race with boats that row and sail, over a fairly long course taking several days. But the racers don't sleep in their boats. Instead they do a stage each day, sleeping and partying on shore in nice prearranged places each night. So the "racers" need carry no gear except what they need during the day and a rescue boat is always nearby. I think each boat must have at least two crew. So what sort of boat do you take? A true sailboat will be helpless in calm and a true rowboat will get left behind in a breeze. Norm wanted something that would row well but convert quickly to sailing and even do hitches with oars and sails together at the same time. He wanted four oarsmen.

I sat with him at McDonald's one day and we sketched this:

The idea was a boat long enough to take four at the oars, with a folding rig that could be left up while rowing or quickly taken down and up again as the winds advised. I suggested a V bottom as it would row the best and beaching was not going to be a problem. The lugsail was lifted from the Normsboat. (I see we were thinking at the time of offset oarsmen each with a single long oar but it was first rowed with pairs of oars. I have been told that rowing with single long oars is preferred in rough water but that way you will always need an even number of oarsmen.)

The plan was to build in Europe and leave the boat there, so the drawings had to be in metric dimensions. I had never done metric because I found when I first started that metric tapes and scales were not commonly available in the US, still aren't, so I stuck with English measures. But I did draw this one in metric and was always worried about real goofs going unnoticed by me. I don't know if there were any. The boat was built in Estonia, I think, in the back of a car repair garage by a non boatbuilder. But that is OK. My boats are designed to be done that way. I never heard from the builder concerning any mistakes although I suspect he is the type of guy who forges ahead regardless and gets it done. I thought he did a fine job and I should say that there are some major twists in the panels in the bow area to deal with. I can see small changes from the plans but nothing I might not have done myself. He has a slotted gunnel. And he used a modified flag pole to replace the wooden one shown on the drawings. I should mention here that I am pretty sure a buoyant wooden sailrig is a safety factor for a sailboat in that it will prevent a capsized boat from turning turtle by my experience. I still say wood is the best material for a small sailboat. But if you have the proper flagpole at hand......

I used my usual pivoted leeboards, with one hitch to the usual. I thought she needed two, one on each side, to have enough lateral board area in a tough slog to windward. In the photos you can see the guards on the gunnel.

The Raider was finished in time for the 2008 Finnish Raid. Norm jetted over a bit early to sort it out or at least get used to it. He took along his Normsboat sail. The race was apparently its first time in the water, more or less. Here it is being paddled out for a sail:

And here it is with some of its rowing crew:

Norm assures me these are hardy men, Vikings all! That is Norm, I think, in the bow seat with no oars urging them on. Can't you hear him yelling, "Come on! Pull! Pull! Break your backs!", just like in Moby Dick. Looking at the photo I thought they might do better by sitting a little higher on say a flotation cushion and maybe with longer oars, but you never know. I gave each man a meter of space as I recall and that looks to be enough. You can see the folded rig is OK. Norm thought he might revise it to fold a bit lower.

Well, I can't tell you how Norm and crew did cuz I don't know. But they did it!

Raider is a taped seam boat, needing ten sheets of 3/8" plywood.

Plans for Raider are $40.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the "ketchooner" rig, featuring his own polytarp sails, that is shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Batista's of www.breakawaybooks.com, printer of my book and Max's book and many other fine sports books. Boat is done, shown here off Cape Cod with mothership Cormorant in background, Garth's girls are one year older. Beautiful job! I think Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat.

And a new Down Under Blobster is off cruising under outboard power as it waits for its sailrig.

A view of the Caroline prototype showing a lot of the inside, crew on fore deck. Beautiful color:

And here is another making I think its maider voyage in the Texas 200. (I'm told the Chinese rig will be replaced by the blueprint rig.)

I gotta tell you that on the Caroline bilge panels I made an error in layout and they are about 1" too narrow in places on the prototype plans. I have them corrected but it always pays, even with a proven design, to cut those oversized and check for fit before final cutting.

And a Deansbox seen in Texas:

And in Texas Gordo Barcom has completed the first Laguna and I hope to give a full report soon. Here he blasts along on his first flight:

The Leinwebers have ganged up on me to rename the Sandrasboat to RioGrande. And here is a photo of Sandra in her RioGrande on the Rio Grande. We have to sort out some fit problems Chuck reported he had in building but then it will go public. It is essentially a decked Toto.

A Twister goes together in good shape:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)