Rob RZ took this photo of a great AF4 by Joe Stromski shown here in its "family use" mode. GREAT JOB!

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15Oct09)This issue will repeat the transom height essay. The 1 November issue will take another look at ballast requirements.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

Transom Height

This one is about matching your outboard motor to your transom. Or should I say matching your transom in a homebuilt boat to your outboard motor.

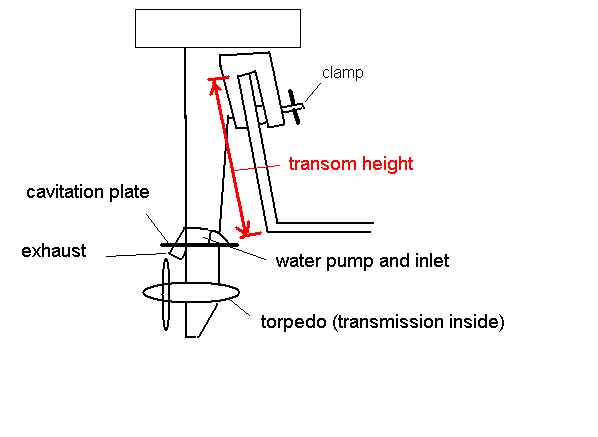

Here are the basics of your outboard's lower unit:

The question is, "What is the correct transom height for the motor."

IT ALL DEPENDS....

For one this I should say up front that the tilt of the transom is almost always about 15 degrees as called for by the motor makers. Most motors have some adjustment and some will even mount to a plumb transom. But if you are designing a powerboat start with 15 degrees and you will be on first base.

Now back to our question. Motors vary in the length of the lower units. BUT I have never seen one that needed a transom height less than 15". In fact I think that was the standard for a long time and almost any older motor you pick up will have this "SHORT SHAFT". But there are lots of LONG SHAFT motors out there, even with small hp heads. I think the standard in long shaft is 20" and often they are made by inserting a 5" extension in a short shaft lower unit. I suppose if you find one of these you can convert it back and forth, or maybe find an extension kit for your short shaft motor. Actually I think long shaft motors are far more common now than in the old days and there are motors even longer than 20".

I think what has happened over the years is that it was realized that small powerboats usually sink from waves over the stern so raising the transom height is a good thing. And long shaft motors are really common as power units for sailing boats where a 15" transom is just not in the cards. But we'll talk about that more later.

FINE TUNING...

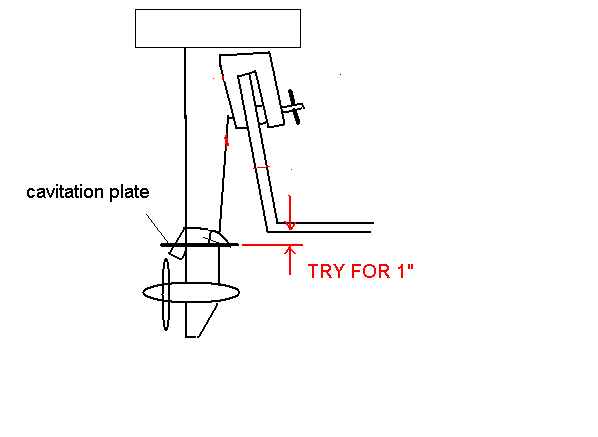

Actually if you ask a mechanic how the motor should be mounted he will likely answer nothing like "use a 15" transom" or whatever. Here is the general rule I have always heard for actually getting the motor height correct. FOR ALL SMALL POWERBOATS THE CAVITATION PLATE SHOULD BE 1" BELOW THE BOTTOM OF THE HULL. Like this:

That is how I have rigged my motors and have had no trouble. I assume the cavitation plate acts to prevent air from traveling down the shaft to the prop at which point the prop will start to push on air instead of water.

I guess the water pump and its inlet, which are right above the cavitation plate, will always be immersed given something like ordinary hull trim.

BUT I'VE GOT TO TELL YOU...

... that is you ask this question of a mechanic who installs 200hp outboards on skiboat hulls you will get a different answer. They told me that without question the cavitation plate should then never be below the bottom, instead always about 1/2" to 1" above the bottom. Otherwise you will get wild steering! Now, I don't think I am in danger of that happening with anything I ever designed but some of you adventurous types might keep it in mind.

STILL MORE FINE TUNING...

You might try for more speed by raising the motor above the 1" scripture. It may give you a bit more speed. It is very easy to experiment. Simply slide a stick between the top of the transom and the motor hanger and reclamp the motor. Most clamps will allow for an inch or two of experimentation. I never saw any change with my AF4 doing this.

Now, you might say, "I've got a long shaft motor and a short shaft transom!" I see no real harm here. The prop and water pump will sit well down in the water now and will hit bottom sooner and I suppose might slow you down a bit.

NOW FOR A CHALLANGE...

The example above is for the usual powerboat, with a flat aft run which is really the best for a straight powerboat. What if you are putting a motor on a sailing hull with a stern that sweeps way above the water?

Here is my experience with my Birdwatcher, which is swept up and to a point at the stern. The motor can't be mounted at all in the stern since it is a double ender with the rudder at the end point. So I put a motor mount off to the side about 2' forward of the stern tip. I knew about the 15" standard by then and guessed at where the waterline would be and made the motor mount to be 15" above the waterline in normal trim. But a light boat with a lot of rocker is going to rock back and forth quite easily and with the Birdwatcher once the motor was running I could hear the exhaust popping loudly as I walked forward (say to handle an anchor) so on the advice of Motor Max I cut my add on transom down an inch which helped. At walking speed in normal trim I think it is just right. At full speed, which seems to be 6mph with any amount of horsepower, the stern squats way down to the point the motor mount is starting to skim the water! This with a boat that probably weighs about 800 pounds.

So some of you might note now that I never have designed a double ended sailboat. One of the lessons I learned from Birdwatcher is that a normal transom can be a wonderful thing. You can hang a motor back there and use a normal rudder and tiller too!

Here is an example of how I design them now, this example being Bill Moffit's Mikesboat;

Pretty simple for me: I just design the transom to have a top edge still about 15" from the bottom of the hull which is this case is about 8' forward of the stern. The stern sweeps up maybe 9" from there leaving about 6" of "transom" depth at the motor. The motor plate is just a 2x6 here. The mount is part of a motor well, well blocked off from the main hull by a watertight bulkhead. It has to be that way or else the boat would swamp in a jiffy from any serious stern wave. As it is any water that slops above that transom just ends up in the well and returns to the lake through drains in the bottom of the well. I've done several boats this way like Caroline and Philsboat and Mayfly16. And no one has told me the transom height was way off.

Now, a motor in a deep well is not that easy to use, right? Essentially you start the thing by leaning way back, get it headed in the right direction and steer with the tiller, as I do with Birdwatcher. Docking is more difficult but what else is there to do?

...thus someone invented the long shaft outboard.

Jonsboat

JONSBOAT, POWER SKIFF, 16' X 5', 200 POUNDS EMPTY

Jonsboat is just a jonboat. But where I live that says a lot because most of the boats around here are jonboats and for a good reason. These things will float on dew if the motor is up. This one shows 640 pounds displacement with only 3" of draft. That should float the hull and a small motor and two men. The shape of the hull encourages fast speeds in smooth water and I'd say this one will plane with 10 hp at that weight, although "planing" is often in the eye of the beholder. I'd use a 9.9 hp motor on one of these myself to allow use on the many beautiful small lakes we have here that are wisely limited to 10 hp. The prototype was built by Greg Rinaca of Coldspring, Texas and his boat is shown above when first launched with a trolling motor. But here is another one finished about the same time by Chuck Leinweber of Harper, Texas:

In the photo of Chuck's boat you can see the wide open center that I prefer in my own personal boats. To keep the wide open boat structurally stiff I boxed in the bow, used a wide wale, and braced the aft corners.

I usually study the shapes of commercial welded aluminum jonboats. It's surprising to see the little touches the builders have worked into such a simple idea. I guess they make these things by the thousands and it is worth while to study the details. Anyway, Jonsboat is a plywood copy of a livery boat I saw turned upside down for the winter. What struck me about that hull was that its bottom was constant width from stem to stern even though the sides had flare and curvature. When I got home I figured out they did it and copied it. I don't know if it gives a superior shape in any way but the bottom of this boat is planked with two constant width sheets of plywood.

Greg Rinaca put a new 18 hp Nissan two cycle engine on his boat, Here is a photo of it:

The installation presented a few interesting thoughts. First I've been telling everyone to stick with 10 hp although it's well known that I'm a big chicken about these things. Greg reported no problems and a top speed of 26 mph. I think the Coast Guard would limit a hull like this to about 25 hp, the main factors being the length, width, flat bottom, and steering location. Second, if you look closely at the transom of Greg's boat you will see that he has built up the transom in the motor mount area about 2". When I designed Jonsboat I really didn't know much about motors except that there were short and long shaft motors. I thought the short ones needed 15" of transom depth and didn't really know about the long shafts. Jonsboat has a natural depth of about 17" so I left the transom on the drawing at 17" and did some hand waving in the drawing notes about scooping out or building up the transom to match the requirements of your motor.

I think the upshot of it all is that short shaft motors need 15" from the top of the mount to the bottom of the hull and long shaft motors need 20". There was a lot of discussion about where the "cavitation" plate, which is the small flat plate right above the propellor, should fall with respect to the hull. I asked some expert mechanics at a local boat dealer and they all swore on a stack of tech manuals that a high powered boat will not steer safely if the cavitation plate is below the bottom of the hull, the correct location being about 1/2" to 1" above the bottom. But Greg had the Nissan manual and it said the correct position is about 1" BELOW the bottom. Kilburn Adams has a new Yamaha and its manual says the same thing. So I guess small motors are different from big ones in that respect.

But it seems to be not all that critical, at least for the small motors. Greg ran his Jonsboat with the 18 hp Nissan with the original 17" transom for a while and measured the top speed as 26 mph. Then he raised the transom over 2" and got the same top speed!

There is nothing to building Jonsboat. There five sheets of plywood and I'm suggesting 1/2" for the bottom and 1/4" for everything else. It's all stuck together with glue and nails using no lofting or jigs. I always suggest glassing the chines for abrasion resistance but I've never glassed more than that on my own boats and haven't regretted it. The cost, mess, and added labor of glassing the hull that is out of the water is enormous. My pocketbook and patience won't stand it. Glassing the chines and bottom is a bit different because it won't show and fussy finishing is not required.

Plans for Jonsboat are $25.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the "ketchooner" rig, featuring his own polytarp sails, that is shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Batista's of www.breakawaybooks.com, printer of my book and Max's book and many other fine sports books. Boat is done, shown here off Cape Cod with mothership Cormorant in background, Garth's girls are one year older. Beautiful job! I think Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat.

And a new Down Under Blobster is off cruising under outboard power as it waits for its sailrig.

A view of the Caroline prototype showing a lot of the inside, crew on fore deck. Beautiful color:

And here is another making I think its maider voyage in the Texas 200. (I'm told the Chinese rig will be replaced by the blueprint rig.)

I gotta tell you that on the Caroline bilge panels I made an error in layout and they are about 1" too narrow in places on the prototype plans. I have them corrected but it always pays, even with a proven design, to cut those oversized and check for fit before final cutting.

And a Deansbox seen in Texas:

And in Texas Gordo Barcom has completed the first Laguna and I hope to give a full report soon. Here he blasts along on his first flight:

AN INDEX OF PAST ISSUES

Hullforms Download (archived copy)

Plyboats Demo Download (archived copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)