Contents

Emergency Flotation

I THINK IT HAS BEEN TEN YEARS....

.... since I ran this essay about emergency flotation. Well back at the

missile plant they taught us to always put the conclusion in the first

paragraph because it has been proven few will read past it. So Agatha

Christie would start her mystery novel with "The butler did it." In

this case I express my opinion that an open wooden boat, with no built

in emergency buoyancy chambers or such, cannot be self rescued from a

swamping in a routine way, especially in rough conditions. Thus I have

avoided putting sail rigs on open boats meant for rowing or paddling.

Here is why....

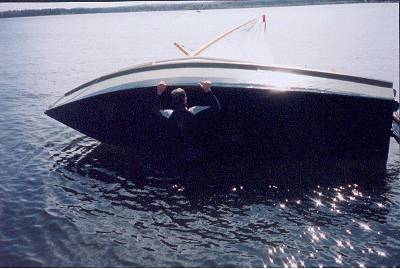

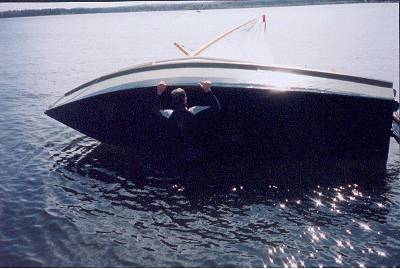

REMEMBER THIS PHOTO?...

Here Herb Mcleod is climbing up the bottom of his capsized AF3, putting

his weight there which will pull the boat back upright. What I want to

point out here is that the boat is floating high on its side on purpose

- it is designed to do that. The cabin is watertight except for the top

opening, which is on centerline and well above the sideways waterline.

Similarly there is a buoyancy/storage box in the stern to float that

end high, and like the cabin, its centerline hatch is well about the

sideways waterline. So the cockpit floods a bit but the cabin and stern

box stay dry and float her high on her side as the boat waits for you

to put your weight on the leeboard and pull everything upright again.

There are other ways to do emergency flotation.

THE SAMPLE BOAT...

Figure 1 shows the "boat" I will use in the examples. It's not much of

a boat but has the overall size of a small sailer. Its main attribute

is that, being rectangular in every way, it makes figuring volumes in

the coming examples very simple.

The boat weighs 100 pounds and is intended to float two people who

together weigh 300 pounds. So the total floating weight is 400 pounds.

Since fresh water is supposed to weigh 62 pounds per cubic foot, the

boat will displace about 6.5 cubic feet of fresh water. On this hull

that occurs when the hull sinks 2.2" into the water at level trim. (The

density of sea water varies but is usually about 5% greater than fresh,

so the draft of the boat there would be about 5% less)

CAPSIZE!...

Figure 2A shows the open hull knocked on its side and flooded. The crew

has abandoned ship. An open wooden hull with no ballast or extensive

use of metal parts should float about half in and out of the water when

on its side. Here is why. The density of dry wood is usually about 30

pounds per cubic foot, about half the density of water. So this 100

pound wooden boat has about 3.3 cubic feet of wood in it. If completely

submerged, that would displace 3.3 cubic feet of water or about 200

pounds worth. Half submerged it would displace 100 pounds of water,

that is, the weight of the empty boat. And that is where it would want

to float on its own.

Anyone who weighs more than 100 pounds trying to sit on top of the

swamped hull in this attitude will completely push the boat under. (But

if this were a heavily planked boat weighing 300 pounds with 10 cubic

feet of wood, we'd have over 600 pounds of displaced water when

completely submerged. That would float the heavy boat plus a big man on

top of the swamped hull.)

Look at Figure 2B. here the boat is being righted without anyone

depressing the hull with their weight. Half of the structure stays

submerged in the process. She'll roll up one quarter full, about 12

cubic feet of water on board, about 750 pounds worth! Sometimes if you

try to retrieve a flooded hull like this it will collapse from the

weight of the water.

Many boats are righted after capsize by placing crew weight on the

centerboard and that weight depresses the hull such that much more

water is taken on and the righted boat can be awash. The problem can be

compounded by an open centerboard or daggerboard case which doesn't

come up to the level of the rails. The open top may be submerged in the

swamped hull and water can stream in freely as you try to bail.

As I recall L. Francis Herreshoff once wrote about reboarding a flooded

pram. Swim alongside and bail with your hat. Or shove the swamped boat

hard forward while swimming to make trapped water surge over the stern.

Then reboard over the stern. I think he used the word "heartbreaking"

somewhere in the procedure.

It's interesting to speculate about what happens if you rotate the

capsized hull to the inverted position as in Figure 2C. It looks like

an air pocket of one quarter the hull's volume will be trapped, that is

about 750 pounds of potential buoyancy, enough to float everyone high

and dry if the boat can be kept from rolling and letting the air out.

STABILITY...

If you have the buoyancy needed to float everyone in the recovered

boat, you may not have sufficient stability to reboard. Here is what

happens. As you grab the rail and try to pull yourself up into the

boat, you heel the hull to your side. That causes the free water in the

recovered boat to slosh to your side and with it comes its considerable

weight. The heel will continue to increase. The rail may go under and

recapsize the boat. I think by the best solution is to reboard over the

stern. You.ll likely need a well thought out ladder or toehold to do

that. Sometimes the rudder can be rigged to be a step.

END BOX FLOTATION...

Next try an improvement. Figure 3 shows the boat fitted with water

tight air boxes in each end, each 3' long such that only half the boat

is open. We'll assume the weight stays at 100 pounds.

Now what happens in a knockdown?

Floating on its side with no crew weighing her down she will sink only

2.5" instead of the 18" of the open boat!

When righted that 2.5" will amount to about 100 pounds of water, about

1/7th of the water in the open boat. It's about 12 gallons that will

need to be bailed. You could easily reboard and sail with that much

water on board if the stability of the sloshing water were not a

problem. But it probably would be. I think my first try would be to

reboard over the stern, bail the water and bring on the passenger.

The end boxes have a huge volume and buoyancy. They will float about

700 pounds each. You can climb on board the upset hull from either end

and it will stay pretty level. You can't submerge it with your weight.

But if you try to do the same job with a single box, say in the bow

alone, she may try to float straight up and down like a buoy. She may

be very difficult indeed to recover.

This system of end boxes is my current favorite. I use the end boxes as

storage volumes with access provided by narrow covered hatches on

centerline. My customers like to make the hatches bigger and bigger but

one must remember that even though the hull is floating in just a few

inches of water, a big wave can come along and slop into your hatches

and there goes your flotation. The big open space between the boxes

makes a good cockpit and sleep spot.

BOTTOM BOXES

What if we put the air box in the bottom half of the boat instead of in

the ends, as in Figure 4? If we make a double bottom 9"above the real

bottom the capsized boat will float 2.5" deep on it's side as before.

But when the hull is righted, it works out that a lot less water

remains on board than in the previous example. In fact with this layout

ther is no reason to not put drain holes trhough the side just above

the double bottom and let the trapped water drain out on its own. The

volume between the bottom and double bottom would displace close to

1500 pounds, plenty for you and your crew. Your boat is one step away

from being a Sunfish type, that is totally decked and water shedding.

I see some problems with the bottom box setup. Rot might be a trouble

in a wooden hull because the narrow volume may be hard to ventilate.

Also the low narrow volume may not be a friendly place to stow gear.

And it might be heavy. The deck must be stiff and strong enough to

support the crew. The previous example didn't have that problem because

crew weight is also supported by the water direclly below the bottom

and the end decks need not support any crew.

I've seen several fiberglass boats that used solid foam slabs to effect

a solid double bottom. That had large openings in the transoms to drain

any water. I've seen some with no transoms at all! In truth these boats

are really foam boards with fiberglass streamlined bump shields. But

watch out. Foam weighs more than people realize in the volumes needed.

In the baby barge example we'd have 24 cubic feet of it - maybe 60

pounds and a 60% increase in bare boat weight.

SIDE BOXES...

What if we put the emergency flotation volume in the sides of the hull

as in Figure 5?

On its side this empty hull will float in just over an inch of water!

If the crew hops onto the sideways boat she will sink down less that

six inches provided the side boxes are at least that deep. And when

righted there will not be a drop aboard. She's ready to go.

This setup is often seen on side decked daysailers that were common in

years past. Those boats usually didn't really have boxes along the side

decks but if water doesn't slop over the edge of the decks the effect

is the same. Sometimes these boats can have air bags or slabs of foam

secured under those side decks just in case.

Deep side boxes cut into the living space of a boat and that can

sometimes be a problem. In a narrow boat it usually means the crew must

sit on top of the boxes instead of down inside the hull. It works fine

in some cases allowing for comfortable hiking.

Birdwatcher type cabin sailers use this side box system very

effectively. Wide side decks are raised above the heads of the low

seated crew, who now view the world through watertight plastic windows.

The crew's low down weight and high wide side decks make this type of

boat about unswampable even without ballast. There are no boxed

chambers and all the interior volume is usable.

EFFECTS OF HULL SHAPING...

Unlike my sample barge, most real hulls have pointy ends. In every

scheme of flotation I've mentioned, the pointed ends would take away

some airbox volume. So I'd expect the emergency flotation to be

decreased over the barge case. In addition, pointed ends can reduce the

volume in those extremes and make reboarding over the ends riskier.

However, the effect of a sweeping sheer is usually quite good for

swamped stability. Air boxes in the hull's ends are well above the

swamped center. Roll will be resisted and even if the rail goes under,

she should roll upright again. She may refuse to stay inverted. But a

hull with double bottom may behave the opposite way. That may be more

stable belly up than down.

Contents

Mayfly16

SAILBOAT, 15' X 5.5', 350 POUNDS EMPTY

Mayfly16 is large enough to swallow up three men or maybe a family

with two kids. She has two benches that are 7' long and there should

be plenty of room for all. I would say that her fully loaded maximum

weight might be 900 pounds and her empty weight about 350 pounds,

leaving 550 pounds for the captain and crew and gear.

At the same time the Mayfly16 can easily be handled solo, although

with just the weight of her skipper she will not be as stable as when

heavily loaded. The boat also has two large chambers for

buoyancy/storage and I can see her used as a solo beach cruiser

because the floor space is large enough for a sleep spot. I've made

her deep with lots of freeboard.

Mary and George Fulk built the prototype and passed by here with the

prototype on their annual migration north for the summer and I had a

chance to see and sail in Mayfly16 for a short bit. Weather was hot

and the wind light and steady, perfect for testing. She sailed quite

well I thought and everything worked as planned. It certainly was

roomy and easy to rig and use.

The balanced lug rig sets on short spars and sails very well reefed,

in fact can be set up with jiffy reefing. The spars are all easily

made and stowed, the mast being but 14' long setting 91 square feet

of sail. In addition there are oar ports for those with lots of time

and little money and a motor well for those with lots of money and no

time. Two horsepower is all that a boat like this can absorb without

going crazy.

The motor well is an open self draining well that uses the full width

and depth of the stern. It will come in handy for storing wet muddy

things you don't want inside the boat, like boots and anchors. I've

suggested in the plans that the rudder can be offset to one side a

bit to give more room for the motor. We did not use George's little

Evinrude since the boat sailed easily in all directions, but George

says the sidebyside sharing on the stern of the motor and rudder

works fine. There was no interference with the rudder. (As with any

outboard on any sailboat, the motor has a desire to grab the sheet

with each tack so you usually have to tend the sheet a bit.)

Mayfly16 uses conventional nail and glue construction needing six

sheets of 1/4" plywood and two sheets of 1/2" ply.

Plans for Mayfly16 are $35.

Contents

Prototype News

Some of you may know that in addition to the one buck catalog

which now contains 20 "done" boats, I offer another catalog of 20

unbuilt prototypes. The buck catalog has on its last page a list

and brief description of the boats currently in the Catalog of

Prototypes. That catalog also contains some articles that I wrote

for Messing About In Boats and Boatbuilder magazines. The Catalog

of Prototypes costs $3. The both together amount to 50 pages for

$4, an offer you may have seen in Woodenboat ads. Payment must be

in US funds. The banks here won't accept anything else. (I've got

a little stash of foreign currency that I can admire but not

spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara

race. Shown here on its first sail except there was no wind.

Hopefully more later. (Not sure if a polytarp sail is suitable

for a boat this heavy.

Here is a Musicbox2 I heard about through the grapevine.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the

"ketchooner" rig, featuring his own polytarp sails, that is shown

on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Batista's of

www.breakawaybooks.com, printer of my book and Max's book and

many other fine sports books. Boat is done, shown here off Cape

Cod with mothership Cormorant in background, Garth's girls are

one year older. Beautiful job! I think Garth is using a small lug

rig for sail, not the sharpie sprit sail shown on the plans, so I

will continue to carry the design as a prototype boat.

And a new Down Under Blobster is off cruising under outboard

power as it waits for its sailrig.

A view of the Caroline prototype showing a lot of the inside,

crew on fore deck. Beautiful color:

And here is another making I think its maider voyage in the Texas

200. (I'm told the Chinese rig will be replaced by the blueprint

rig.)

I gotta tell you that on the Caroline bilge panels I made an

error in layout and they are about 1" too narrow in places on the

prototype plans. I have them corrected but it always pays, even

with a proven design, to cut those oversized and check for fit

before final cutting.

And a Deansbox seen in Texas:

And in Texas Gordo Barcom has completed the first Laguna and I

hope to give a full report soon. Here he blasts along on his

first flight:

A Twister goes together in good shape:

Contents

AN INDEX OF PAST ISSUES

BACK ISSUES LISTED

BY DATE

SOME LINKS

Mother of All Boat

Links

Cheap

Pages

Duckworks

Magazine

The Boatbuilding

Community

Kilburn's Power

Skiff

Bruce Builds

Roar

Dave

Carnell

Rich builds

AF2

JB Builds

AF4

JB Builds

Sportdory

Hullforms Download (archived copy)

Plyboats Demo Download (archived

copy)

Brokeboats (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)

Barry Builds

Toto

Table of

Contents