Gene Berry experiments with a River Runner that has been narrowed 6" to make paddling easier. No problem, says he.

Contents:

Contact info:

Jim Michalak

118 E Randall,

Lebanon, IL 62254Send $1 for info on 20 boats.

Jim Michalak's Boat Designs

118 E Randall, Lebanon, IL 62254

A page of boat designs and essays.

(15January2013) This issue will start to rerun the old "drawing a boat" essays that first ran in 2005. These were pretty well "lost" due to my neglect and two servers going out of business, but I think I can recover them thanks to a dedicated fan.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

Drawing Tools

THE DESIGN SPIRAL....

Designing boats can be an adventure. You never really know exactly where you are headed or what you will learn on the way. I like to think of the design process (of anything, not just boats) as a line that spirals to a bullseye as in Figure 1. An old timer or a lucky stiff might start out right at the bullseye and get it correct at the start. But most of us won't. We'll start in the middle of the line somewhere and with each stroke of the eraser and pencil progress a little closer to the targer. With enough trial and error we'll get there eventually. The unlucky ones might regress the other way and spiral away from the desired results. In some cases and experienced designer will spiral outward and conclude that the desired boat is impossible.

(And I'm reminded of the time a long time ago when at the missile factory about a hundred of us burned the midnight out for maybe six months working to cram enough fuel into a ramjet missile to meet the range needs and then the lowly weights guy pointed out the the result was so heavy that the booster could not get the heavy result up to flight speed. And the whole project spiraled to a crash.)

Design is almost always an iterative process. At the spiral's bullseye all the boat's elements are in harmony and the pieces of the puzzle all fit. But just as in solving a jigsaw puzzle, in design there is a lot of trial and error fitting involved. I think the best example of that is in sizing sail rigs. The amount of sail you can carry is dependent upon the stability of the hull so you might think that you could pick a proper sail area knowing the hull's stabiltiy. But the stability itself is greatly affected by the size of the sail rig and you must assume a rig size before calculating stability! So which came first, the chicken or the egg? It doesn't matter, but you've got to assume one comes first to get started. Then you proceed through the design process, checking calculated values of stability or sail rigs against assumed values, make adjustments, and move another step closer to the bullseye.

DESIGN EQUIPMENT...

Drawing boats is an inexpensive adventure. With one avoidable exception (determining the shapes of twisted and bent panels) I think no computer gear is required. In fact that gear might get in the way and slow you down. And you might find yourself designing projects that are limited by the capabilities of your gear. An inexpensive hand calculator is almost always sufficient. Drafting tools can be minimal. A three foot by four foot sheet of 1/2" plywood is a good drawing board although you will have to surface it with a layer of heavy paper to negate its grain. I met Phil Bolger about 30 years ago when he was still working in his ancestral house. He was quite famous and seeing his drawing room was quite a treat. At that time he had a full sized sheet of plywood atop a stack of concrete blocks and could make very large drawings on it for some of the very large boats he was drawing. There was no computer gear and he had no intention of getting any although he said the salesmen were hounding him a bit. Ten years later he had moved into his boat home and his drawing board was quite small, maybe 2 foot square at the most. Perhaps he had a larger board on shore somewhere. At any rate I think he later went in a real office complete with big drawing boards and electronics. He always did his drawings by hand and I'm sure most of you know that he had a true artist's hand and for him to use a cad program to put out final drawings would be a crime.

No T square or drafting machine is needed, another thing I learned from Bolger who told me T squares are just for quickie diagrams. Don't believe Howard Chapelle used one either. We'll get into the subject of avoiding the T square later.

About three drafting triangles would be nice in different sizes. Get at least one that is quite large.

I use an ordinary three sided architect's scale for measuring. It has fine graduations and when working in 1/8 or 1/12 scales will give accuracy sufficient for boatbuilding from the scale drawings.

I use an aluminum yardstick meant for drywall workers as a long straightedge.

I use ordinary .5mm mechanical pencils that I get at the discount store. Last I saw him work Bolger was using very fine and hard drafting pencils that he kept to the sharpest edge. His preliminary lines were so fine that they were to me hardly visible. He had great eyes and hands and could work with accuracy in much smaller scales than I can.

For a compass I modified a discount store bow compass to hold a .5mm mechanical pencil on one arm by strapping the pencil to the metal compass arm with wire and then potting it into place with a blob of epoxy putty.

And I have a simple plastic protractor. This and the triangles are two of three things I bought at the drafting supply.

As for "Ships Curves", none are required or needed or even suggested because with them you can easily draw curves that can't be easily made full size on the real boat. So I have no drafting curves and think their use can be detrimental. Using "splines", which are long flexible battens, to draw those curves will solve that problem. I now use a plastic spline purchased at the drafting supply and that was over ten years ago and even then they were special order. I dread to think that some day they will be unobtainable. It is about 3' long and about 1/8" x 1/4" in cross section with a groove on the top for the lead weights (usually called ducks or whales) that hold it in place. If splines become extinct I will have to go back to making my own from wood. In one of Howard Chapelle's books he describes drafting gear then current and the making of one's own splines. As with almost all homemade things, once you get the hang of it the homemade spline can be better than the factory spline. Chapelle shows how one can taper and thin the splines to make them throw tricky curves into the right places. But like the ships curves, remember that anything that is tricky to draw will be even trickier to make full size and one of the great advantages of drawing with splines is that they bend in the same way as real lumber. If your drawing goes quickly because the bends are easy, so it will be with the real boat. If you torture your splines with kinky curves, so it will be with the real boat.

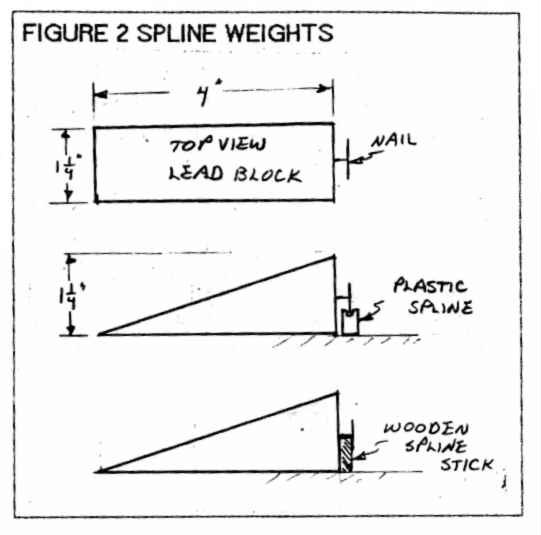

I made my own spline weights, being shocked at the price of the store bought weights (the plastic splines were shockingly cheap at the time at least). First I cast lead (old wheel weights work great) into blocks 4" x 1-1/4" x 1-1/4". Then I sawed the blocks across diagonally to give two triangular blocks. Then I drove a roofing nail into the fat end of each block so that it fell just right into the slot of the drafting spline as shown in figure 2. I wrapped the lead with paper tape to keep it from marking everything up and glued a rubber layer to its bottom for friction. Figure 2 also shows the set up used with the simple stick spline.

For drafting paper I prefer to use the backs of old blueprints which are 24" x 36". My second choice is the matte side of drug store poster cardboard which is about 22" x 28" and almost all my older designs like Piccup Pram were done on the poster cardboard. Someone once told me that William Jackson who designed many of the boats you'd see in popular magazines in the 50's and 60's liked to draw on ordinary brown wrapping paper. I tried it and couldn't see the lines. But I did end up using the heavy wrapping paper to give a nice surface to the plywood drawing board. If a design turns out to be a keeper I trace the lines on drafting mylar using ordinary .5mm lead pencil. It must be handled somewhat with care to avoid smearing. Bolger does his tracings with very fine ink pens but I make way too many mistakes for that.

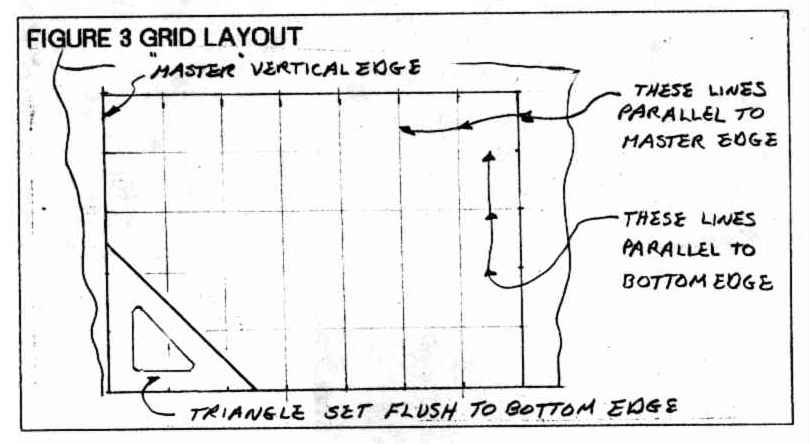

To set up shop you place your board in a comfortable place with good light and surface it with the heavy wrapping paper. Tape your drafting paper to it with any sort of regular tape using no pins. Check the corners of your paper for squareness with that large triangle you bought. It is almost always perfectly square but you must check it. (The post cardboard is seldom square.) If it isn't perfectly square, draw a vertical line up the left or right side using the large triangle set flush with the bottom edge of the sheet. Now lay out a grid of lines all over the paper with all vertical lines parallel to that first vertical and with all horizontal lines parallel to the bottom edge as shown in Figure 3. The spacing of the lines should be between 1" and 3" apart. I like to space the lines a scale 12" apart, so in 1/8 scale they are 1-1/2" apart, and in 1/12 scale they are 1" apart. Don't worry about getting the grid size that will fit exactly on your paper. If the last sectors along one edge aren't the proper size it is of no consequence. All measurements will be taken from this grid so use care in getting it right. And that is how we avoid using the T square. They say the grid method is more accurate than using the T square.

That's about it for buying stuff, maybe $50 worth.

Contents

HC Skiff

HC SKIFF, SHARPIE SAILBOAT, 18' X 5.5', 450 POUNDS EMPTY

HC Skiff is a rework of a "typical sharpie skiff" that appears on page 101 of Howard Chapelle's great book AMERICAN SMALL SAILING CRAFT. I can almost say that if you own only one book about small sailing boats that this is the one to have. The lines of my version are straight out of Howard's offset table. By today's standards it is a long narrow hull, 18' long and about 4' wide on the bottom. The stem rides about an inch above the water, then the bottom goes straight to the deepest point of the hull at about half the length of the hull. Then the bottom sweeps way up above the waterline for a very high and small transom. There were working hulls. Heavy loads could be carried without immersing the stern transom which is always harmful to a boat with no motor. You put everything in the stern and the stern still stays clear of the water. I think a hull shaped like this is little improved upon by any modern flattie skiff thinking. Chapelle said the shape was common all along the East Coast from 1860 to 1900. The prototype shown here was built by Dan Roach of Danvers, Massachusetts, very close to where Chapelle found the original boat he surveyed. Dan wrote quite a bit to me saying it was fast and handy and easily carried his family including the dog. (I'd quote what he said but I lost his email in a computer accident. So will somebody tell me why they put the "empty file" button right next to the "send message" button??)

I used modern plywood construction on HC Skiff. The old boats were nailed together from 1" boards. Then they were left outside in the water until they died. They must have been very heavy both in their construction and in their soakage, not to mention the clams and oysters. My version uses five sheets of 1/2" plywood and five sheets of 1/4" plywood and will weigh a fraction of the original. It's all done with prefab parts and no jigs or lofting.

I had to tinker with the sail rig which was of the same style shown here but at least 50% larger. On the heavy old boats that might have been OK but I'm sure it would be way too much for the lighter plywood boat. I kept the large centerboard. I added hull air boxes bow and stern for a chance at self rescue after swamping. Also added some benches where the original boat was wide open from stem to stern with three simple thwarts.

Plans for HC Skiff are $30.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

I think David Hahn's Out West Picara is the winner of the Picara race. Shown here on its first sail except there was no wind. Hopefully more later. (Not sure if a polytarp sail is suitable for a boat this heavy.

Here is a Musicbox2 out West.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the "ketchooner" rig, featuring his own polytarp sails, that is shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Battista's of www.breakawaybooks.com, printer of my book and Max's old outboard book and many other fine sports books. Beautiful job! Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat. But he has used it extensively on his Bahamas trip towed behind his Cormorant. Sort of like having a compact car towed behind an RV.

And a Deansbox seen in Texas:

Another prototype Twister is well along:

And the first D'arcy Bryn is taped and bottom painted. You can follow the builder's progress at http://moffitt1.wordpress.com/ ....

AN INDEX OF PAST ISSUES

A NOTE ABOUT THE OLD WAY BACK ISSUES (BACK TO 1997!). SOMEONE MORE CAREFUL THAN I HAS SAVED THEM. TRY CLICKING ON...

which should give you a saving of the original Chuck Leinweber archives from 1997 through 2004. They seem to be about 90 percent complete.

Hullforms Download (archived copy)

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)