Drawing Boats 8

In the last Bobsboat issue we made a cardboard model using the panel

expansions developed in the episode before that. If this were to be a

totally taped seam construction we could start drawing the construction

drawing right now. But the way I have done taped seam boats is to

attached beveled sticks to the bulkheads and transom and the stem, at

least to the point where the boat can be solidly assembled initially

with traditional nail or screw and glue construction. Then the builder

can scope his boat out well enough before he dips his hands into

noxious materials. Actually with this method a fellow can start his

project, take it apart and move it, and put it back together.

So how to figure the bevels needed to preassemble the bulkheads, etc.?

First, The Very Basics....

The only way to see the true bevel of a joint between two panels is to

arrange the view on your drawing board such that you see both panels in

edge view. For example:

The First No Brainer...

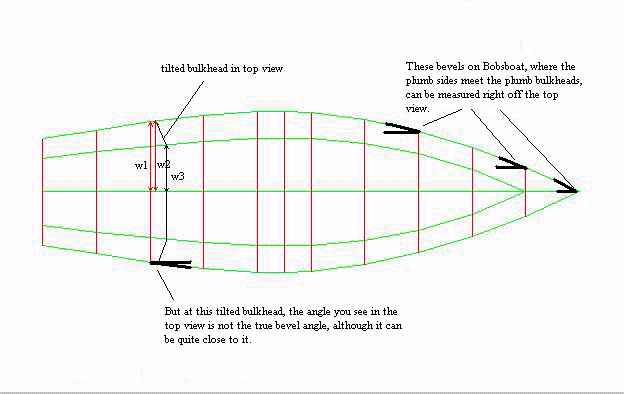

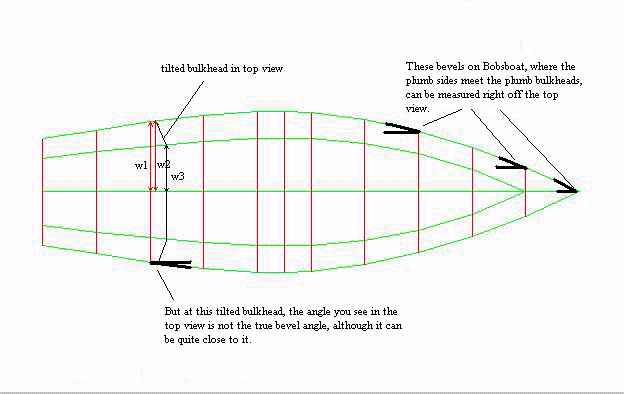

If you have a plumb sided design like Bobsboat, your top view will

often suffice to get nearly all of the bevels required. You will be

looking straight down the plumb sides in the top view and if your

bulkheads, etc. are also plumb, you are seeing it right. Just take a

protractor and measure the bevels right off the top view, like this:

.

.

What if you have a boat with sides that are flared but not twisted,

like many flatiron skiffs? You have to draw another view tilted so you

are looking straight down the side.

I've got a little hint that I have found to save a lot of extra view

drawing: if the amount of flare is small, say 5 degrees, the bevels are

essentially what you see in the normal top view.

Also, if your panels are twisted your bevels will twist with them - a

rolling bevel. You won't be able to predefine a bevel although you

might get it close enough to get started with construction and then

roll the bevel on the job site.

Raked Stem Bevels...

If your sides are flared and have no twist then you will have a raked

stem. You can't just measure this one from the top view. Here is a

guide of one way to do it.

Remember that you need to twist your view such that you are looking

straight down the stem.

Tilted Transoms:

On Bobsboat and on many boats the transom here (and the bulkhead in

front of it) are tilted 15 degrees. On Bobsboat that is for looks but

on almost any boat that will mount an outboard that 15 degree tilt is

standard. It is what almost any outboard is designed for. So a simple

look at the top view, or any view that simply looks straight down the

sides, won't be enough.

No Brainer Number 2...

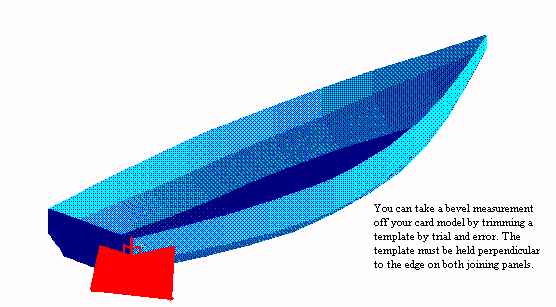

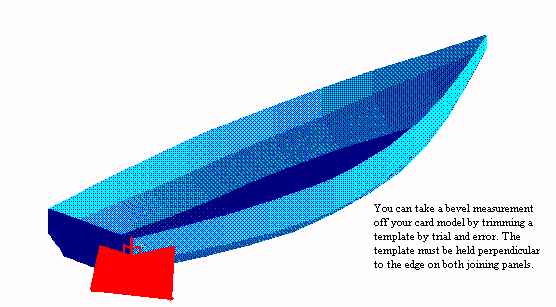

Grab that card model you made last time. Find the intersection of the

panels in question, in this case where the side meets the transom. Mark

lines on both joining panels that are perpendicular to that joint. Now

cut a template that fits exactly at those lines. Like this;

Now use your protractor to measure that angle. You might check the

opposite side with the same template. With a small flimsy card model

this method is not too exact but then again it requires no computer or

twisted thinking so your answer will be pretty close. While you are at

it you might double check the stem bevel you calculated with the same

model.

Next, twisted thinking...

The required bevel can be determined on the conventional drawing board.

Here are the basics:

Essentially here you start by making a true shape projection of the

transom. Then you make another projection that looks straight down the

edge of the transom as shown. These can be done in a jiffy if you are

practiced but if you are just drawing a boat every now and then, you

might have to go slowly and carefully. Then you ought to check it

against the No Brainer Number 2 results. It is easy to twist your

thinking the wrong way!

Now For True Rocket Science!!!

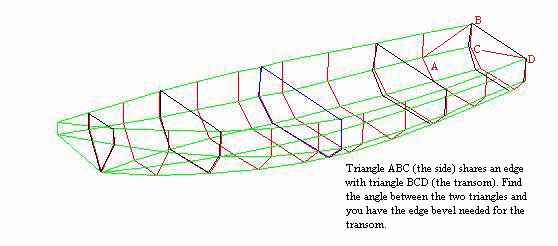

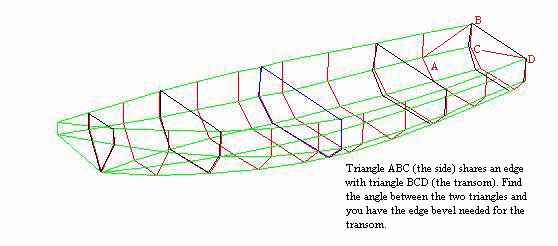

Look at this view of the Bobsboat and note that I have constructed two

triangles, one on the side and one on the transom and they share a

common edge. We want to find the angle between those two triangles and

that is the mystery bevel.

Remember we have already drawn the lines and taken offsets at regular

points. So we can look quickly at our drawing and see the xyz

dimensions of the points. So only four points in xyz space are needed

here to define both joining triangles since they share two common

points.

Hope you paid attention to your university math! You may think that

100% of that stuff was useless in real life but I can assure you that

about 25 years after I graduated I found 1% that I needed.

Take triangle ABC. The plane that triangle lies in (which is really the

plywood panel) can be defined by two joining vectors, vector AB and

vector BC. If you take the CROSS PRODUCT of those two vectors you will

get a third vector that is perpendicular to the plane of triangle ABC

and can be thought of as the "direction" of that plane.

Similarly with triangle BCD. Take another cross product and find its

direction vector.

Now if you take the DOT PRODUCT of those two vectors you will get a

number that represents the cosine of the angle between the two planes!

And from there you can figure what the angle between the two planes is.

There you have it - the mystery transom bevel.

Now don't ask me how to figure cross products and dot products. This is

vector math involving matrices of numbers and is true rocket science.

But you can dig them out of those old math books you probably threw

out. In the mid 60's when I was in school we used to beat these numbers

to death with a Pickett slide rule and a lot of pencils and paper. If

you had thirty kids in a class you would get thirty different answers

to the problem given the errors in the endless calculations required.

BUT NO MORE! Today you plow your way through it once with a spreadsheet

in a PC. Then the machine does the calculation with no error in the

time it takes to tap ENTER. My spreadsheet asks for the xyz offsets for

the four points that define the two panels and then it spits out the

needed bevel angle!

And then I always check the results against my card model just to be

sure. Once your spreadsheet has been debugged it is usually faster to

figure all of the boat's tilted bevels this way!

Contents

Polepunt

POLEPUNT, PUNT, 15' X 3', 110 POUNDS EMPTY

Do you have a swamp in your back yard? Turn that into a positive

thing with a tradional punt that you push through the shallow water

with a pole. I think this sort of boat has a long history and the

similar shape in Chapelle's great book AMERICAN SMALL SAILING CRAFT

goes back to at least the 1700's. Those weren't built of plywood,

of course, and would be a lot heavier than this one. Actually

Chapelle shows the shape of the old one as more elaborate than this

one but I'm pretty sure this one is in no way harmed in function by

the simplicity of its shape.

In particular I drew in a feature that I saw on a commercial

aluminum jonboat. That is a constant width bottom. I used that

feature on my Jonsboat design and it works very well. It might make

the boat easier to build although something like Polepunt is easy

to do in almost any case. I kept the bottom dead flat in the center

7' with no frames there so that you might walk the center as you

push the pole. The boat is narrow at 30" inside on the bottom and

I'm hoping that will make it stable enough to stand in. But such a

light boat will be dominated by your weight and you will need to be

careful how you stand. I've also shown rowlock sockets on the

drawing and this might suit as a rowing boat using a removable

seat. And this might be very suitable for floating streams with

paddles, a substitute for an aluminum canoe. I see no good way to

use a motor on a boat like this. The ends (which are identical) are

swept way upward for good lines at slow speed and won't support any

weight fore and aft. The only chance for a motor would be with an

electric with remote steering so yo can keep your weight forward

for proper trim. I've written words like that for almost all my arm

powered boats and I still get regular photos of those boats with

motor plates mounted on the stern. But I never get photos of those

boats under power most likely because the owner tried it just once

and never again after it tried to stand on its stern when the motor

was fired up. So if you want power, and there is nothing wrong with

that, build Jonsboat instead.

Anyway, our old buddy in Poland, Wojtek Baginski, built the

prototype to perfection. In one of Phil Bolger's books he says the

real trick of designing a successful boat is to get your design

into the hands of the right user, and so it is with Wojtek. Here is

his account of the maiden voyage:

"Here is a brief description of polepunt nautical characteristics.

The first is that polepunt is incredibly stable. During our cruise

the crew (Wojtek Baginski is in the stern in most of these photos

and his boating buddy Wojtek Holnicki in the bow) was often forced

to gather on the stern first, and next on the bow (after boat's

center has passed over the bar) to jump over a tree or a branch

laying in the water, not stopping the punt. We were using the

internal stiffener as a walkway and it helped much to keep the

balance.

The second notice is that polepunt responds to oar action very

well. After more of less a strong push of a pair of paddles she

smoothly went a long distance on calm water. Looks like rowing will

be successful as well, when an oarsman will take a seat at the

center of the boat, and will pull the boat with the pair of 7 foot

oars (we have chosen a pair of heavy ones for the Vistula , because

of possible wind and waves acting on her open area against the

boat). As for using a pole, it's really amazing and effective

power, but needs a bit of experience. Worth learning!

Another notice is that the boat is surprisely strong, I think

because of relatively low ratio of free plywood surface to chine

logs, stiffeners, gunwales and frames. She got a few strong hits

and scrapes from wooden, concrete and stone objects, but generally

everything is OK, external chine logs gave good protection to the

sides in extremal conditions. I laminated the bottom with a

fiberglass twice, inside and outside, by the way.

So, the boat is really useful in various conditions (we checked her

out during 20 km long raft in various water areas including wild

state creek, regulated state creek, small man made lagoon and big

river). I think with her low cost and quick building process she is

a very good proposition not only for beginners but for advanced

adventurers as well (hey don't look at me! :).

Thanks Jim."

Thank YOU, Wojtek!

I want to point out here is that a stream like this clearly isn't

meant for modern boats and if you have a boat like Polepunt you can

navigate it and pretty much have it all to yourself. This can be

really high quality boating.

Nothing to builiding Polepunt, of course. Nail and glue

construction from four sheets of 1/4" plywood.

Plans for Polepunt are $20 when ordered directly from me.

Contents

Prototype News

Some of you may know that in addition to the one buck catalog

which now contains 20 "done" boats, I offer another catalog of

20 unbuilt prototypes. The buck catalog has on its last page a

list and brief description of the boats currently in the

Catalog of Prototypes. That catalog also contains some articles

that I wrote for Messing About In Boats and Boatbuilder

magazines. The Catalog of Prototypes costs $3. The both

together amount to 50 pages for $4, an offer you may have seen

in Woodenboat ads. Payment must be in US funds. The banks here

won't accept anything else. (I've got a little stash of foreign

currency that I can admire but not spend.) I'm way too small

for credit cards.

I think David Hahn's Out West Picara is the winner of the

Picara race. Shown here on its first sail except there was no

wind. Hopefully more later. (Not sure if a polytarp sail is

suitable for a boat this heavy.

Here is a Musicbox2 out West.

This is Ted Arkey's Jukebox2 down in Sydney. Shown with the

"ketchooner" rig, featuring his own polytarp sails, that is

shown on the plans. Should have a sailing report soon.

And the Vole in New York is Garth Battista's of

www.breakawaybooks.com, printer of my book and Max's old

outboard book and many other fine sports books. Beautiful job!

Garth is using a small lug rig for sail, not the sharpie sprit

sail shown on the plans, so I will continue to carry the design

as a prototype boat. But he has used it extensively on his

Bahamas trip towed behind his Cormorant. Sort of like having a

compact car towed behind an RV.

And a Deansbox seen in Texas:

Another prototype Twister is well along:

And the first D'arcy Bryn is taped and bottom painted. You can

follow the builder's progress at http://moffitt1.wordpress.com/

....

Contents

AN INDEX OF PAST ISSUES

A NOTE ABOUT THE OLD WAY BACK ISSUES

(BACK TO 1997!). SOMEONE MORE CAREFUL THAN I HAS SAVED

THEM. TRY CLICKING ON...

http://web.archive.org/web/20050308025339/http://marina.fortunecity.com/breakwater/274/michalak/alphabetical.htm

which should give you a saving of the

original Chuck Leinweber archives from 1997 through 2004.

They seem to be about 90 percent complete.

BACK ISSUES LISTED BY DATE

SOME LINKS

Mother of All Boat

Links

Cheap

Pages

Duckworks

Magazine

The Boatbuilding

Community

Kilburn's Power

Skiff

Bruce Builds

Roar

Dave

Carnell

Rich builds AF2

JB Builds

AF4

JB Builds

Sportdory

Hullforms Download (archived copy)

Puddle Duck

Website

Brian builds Roar2 (archived copy)

Herb builds AF3 (archived copy)

Herb builds RB42 (archived copy)

Barry Builds

Toto

Table of

Contents