Jim Michalak's Boat Designs

1024 Merrill St, Lebanon, IL 62254

A page of boat designs and essays.

(15 October 2022) We calculate displacement. The 1 November issue will reef a lugsail.

IMPORTANT NEWS!! MY OLD EMAIL ADDRESS HAS NOT BEEN WORKING WELL. SOOOO...LET'S CHANGE TO AN AOL ADDRESS THAT HAS WORKED WELL FOR TEN YEARS.

THE AOL ADDRESS IS jimsboats.jim@aol.com

ORDER NEWS

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

... is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the....

ON LINE CATALOG OF MY PLANS...

...which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal.

ALSO...In addition to the Duckworks downloads I also now have access to a large format inkjet printer which is making very nice full sized prints on paper. So I can return to what I started 30 years ago, you order direct from me by snail mail using the address above only with cash or check in US funds with the prices shown on this website, and I mail you full sized 2'x 3' paper prints. The price includes first class mail to US and Canada.

Figuring Displacement

THE VERY BASICS...

One of the real basic errors in boat design is to not match the capacity of the hull to the weight it needs to carry. It's actually pretty easily done. Let's take an example: a fellow wants a 12' skiff to handle two adults. He figures the empty boat will weigh 120 pounds and the adults together at 350 pounds. So he has to float a total weight of 470 pounds.

One thing is for sure: no matter what the shape of the hull, it will sink into the water until it pushes aside, or displaces, 470 pounds of water. (They way I heard it was that ancient Greek mathematician Archimedes figured out the basics while sitting in the bath tub.) Fresh water weighs about 62 pounds per cubic foot and salt water usually about 65 pounds per cubic foot. So the volume of fresh water displaced by the 470 pound boat is 470/62 = 7.6 cubic feet. That was easy!

Next the problem becomes one of shaping the underwater part of the hull such that it displaces 7.6 cubic feet with good flow lines.

METHOD 1: THE PRISMATIC COEFFICIENT...

We talked about the prismatic coefficent in the last issue. Remember that we construct a prism with the same length as the waterline length and the same cross section as that of the boat's maximum beam. The hull will fit neatly into the prism. Divide the volume of the underwater hull by the volume of that prism and you have the prismatic coefficient.

What is interesting to me is that the prismatic coefficient doesn't vary much from one displacement hull to another, as far as normal small boats are concerned. Jewelbox, with a flat bottom and squared off ends, has a prismatic coefficient of about .60

And Toto, with very pointy ends and multichine cross section, has a prismatic coefficient of about .50

So I figure if you were to assume a halfway normal displacement hull has a prismatic coefficient of .55 then you would always be within 10% which is actually pretty good.

So without drawing a line I might say that the 470 pound weight will need a "prism" with a volume of 7.6/.55 = 13.8 cubic feet. The prism could have any combination of cross section and length that will have that 13.8 cubic feet total volume.

Remember that the prism has the same length as the hull's waterline length and cross section as the boat's maximum cross section. Remember we want a 12' boat, but the waterline will be shorter if we want some rake to the ends (for looks) and maybe enough rocker to make sure the stem and stern don't drag the water (for low drag). We might guess that the waterline length will really be about 10'. Then the maximum cross section would have to have 13.8/10 = 1.38 square feet of area below the waterline. If we wanted a flat bottom 3' wide (wide enough to have sailing stability and narrow enough for reasonable rowing) we would have a draft of approximately 1.38/3 = .46' or 5.5".

If we wanted a different cross section than the simple box shape I'm assuming here, we would have to tinker a bit. Draw up a cross section with the 1.38 square foot cross section and see if we like it. Actually in this case I'm going to flare the sides out to 4' at the top of the wale at the cross section. But that won't affect the area under the waterline much. We might sketch out something like this:

METHOD 2: THE CURVE OF AREAS...

This method of the "curve of areas" is an accurate and flexible way of determining the volume of almost any oddly shaped thing. It's actually pretty easy to do but first you need a drawing of the proposed boat (unlike the prismatic coefficient which just needs a general idea of the boat).

Let's take our proposed boat and draw a line on it that represents 5.5" draft, our guess at what is needed to float 470 pounds. Every now and then along the length of the hull we take cross sectional cuts of the hull and measure the area at each cut below the 5.5" waterline. The cuts can be taken anywhere but there must be enough to get a good definition fo the hull. Actually for a normal boat about five cuts will do. The more you take the more accurate your work but five will get you really close. Our example boat might be like this:

The dimensions of the underwater sections are measured right off the paper drawings and the area of each is calculated like this:

Next we graph those underwater areas spacing them the same distance apart as they are on the real hull to get the "curve of area" like this:

The area enclosed under the curve of areas is a volume and is indeed the volume of the underwater hull - it's what we are looking for. In the old days you would measure the areas with a planimeter, a clever and expensive gadget. But you can do well by just breaking down the curve into triangles and trapezoids, figuring the area in each trapezoid, and adding them all up. In the example, second trapezoid from the left is figured by 1/2(175+209)X12 = 2304. Adding the sections together gives us a total of 12500 at 5.5" draft. That equates to 450 pounds of water. So the first guess was off by 20 pounds or about 4%. By the way, the drawing showed a waterline length of 9'5" instead of the first guess 10'.

As mentioned before this method can be used to figure the volume of almost anything. Let's say we wanted to find the weight of a mast. Say the mast is 24' long, 3.5" in diameter at the base and 1.5" in diameter at the top, with a curved taper between. The figuring of the volume might look like this:

1920 cubic inches equals 1.1 cubic feet. Wood usually weighs 25 to 35 pounds per cubic foot. At 30 pounds per cubic foot the mast would weigh 33 pounds.

You can also use the area of curves to find the CG of the object, too. For real simplicity I've seen designers in the aircraft industry draw the curve on cardboard, cut it out and balance the thing on a knife edge. The item's CG will lie on that balance line.

THE COMPUTER METHOD...

Finally you can use your computer to figure it all out. I'm sure all of you know that getting the computer to spit out the right answer might take a lot longer than doing it by hand. The program I used to get the drawings above was Hullform6s which can be downloaded from the links shown at the end of this page. What were the answers that Hullform6s predicts for the 12' skiff with 470 pounds displacement? 5.5 " draft, waterline length of 9'4", and prismatic coefficient of .55! So the first guesses were quite good. But the area of curves method was also excellent, within 4%. It showed the same waterline as Hullforms. Perhaps with more data points to flesh out the curve the hand method would get the same answer as hullforms but I wouldn't bother. You will never guess the weight of the finished boat within 4%.

Jonsboat

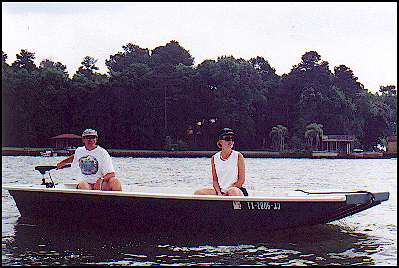

JONSBOAT, POWER SKIFF, 16' X 5', 200 POUNDS EMPTY

Jonsboat is just a jonboat. But where I live that says a lot because most of the boats around here are jonboats and for a good reason. These things will float on dew if the motor is up. This one shows 640 pounds displacement with only 3" of draft. That should float the hull and a small motor and two men. The shape of the hull encourages fast speeds in smooth water and I'd say this one will plane with 10 hp at that weight, although "planing" is often in the eye of the beholder. I'd use a 9.9 hp motor on one of these myself to allow use on the many beautiful small lakes we have here that are wisely limited to 10 hp. The prototype was built by Greg Rinaca of Coldspring, Texas and his boat is shown above when first launched with a trolling motor. But here is another one finished about the same time by Chuck Leinweber of Harper, Texas:

In the photo of Chuck's boat you can see the wide open center that I prefer in my own personal boats. To keep the wide open boat structurally stiff I boxed in the bow, used a wide wale, and braced the aft corners.

I usually study the shapes of commercial welded aluminum jonboats. It's surprising to see the little touches the builders have worked into such a simple idea. I guess they make these things by the thousands and it is worth while to study the details. Anyway, Jonsboat is a plywood copy of a livery boat I saw turned upside down for the winter. What struck me about that hull was that its bottom was constant width from stem to stern even though the sides had flare and curvature. When I got home I figured out they did it and copied it. I don't know if it gives a superior shape in any way but the bottom of this boat is planked with two constant width sheets of plywood.

Greg Rinaca put a new 18 hp Nissan two cycle engine on his boat, Here is a photo of it:

The installation presented a few interesting thoughts. First I've been telling everyone to stick with 10 hp although it's well known that I'm a big chicken about these things. Greg reported no problems and a top speed of 26 mph. I think the Coast Guard would limit a hull like this to about 25 hp, the main factors being the length, width, flat bottom, and steering location. Second, if you look closely at the transom of Greg's boat you will see that he has built up the transom in the motor mount area about 2". When I designed Jonsboat I really didn't know much about motors except that there were short and long shaft motors. I thought the short ones needed 15" of transom depth and didn't really know about the long shafts. Jonsboat has a natural depth of about 17" so I left the transom on the drawing at 17" and did some hand waving in the drawing notes about scooping out or building up the transom to match the requirements of your motor.

I think the upshot of it all is that short shaft motors need 15" from the top of the mount to the bottom of the hull and long shaft motors need 20". There was a lot of discussion about where the "cavitation" plate, which is the small flat plate right above the propellor, should fall with respect to the hull. I asked some expert mechanics at a local boat dealer and they all swore on a stack of tech manuals that a high powered boat will not steer safely if the cavitation plate is below the bottom of the hull, the correct location being about 1/2" to 1" above the bottom. But Greg had the Nissan manual and it said the correct position is about 1" BELOW the bottom. Kilburn Adams has a new Yamaha and its manual says the same thing. So I guess small motors are different from big ones in that respect.

But it seems to be not all that critical, at least for the small motors. Greg ran his Jonsboat with the 18 hp Nissan with the original 17" transom for a while and measured the top speed as 26 mph. Then he raised the transom over 2" and got the same top speed!

There is nothing to building Jonsboat. There five sheets of plywood and I'm suggesting 1/2" for the bottom and 1/4" for everything else. It's all stuck together with glue and nails using no lofting or jigs. I always suggest glassing the chines for abrasion resistance but I've never glassed more than that on my own boats and haven't regretted it. The cost, mess, and added labor of glassing the hull that is out of the water is enormous. My pocketbook and patience won't stand it. Glassing the chines and bottom is a bit different because it won't show and fussy finishing is not required.

Plans for Jonsboat are $25.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

We have a Picara finished by Ken Giles, past Mayfly16 master, and into its trials. The hull was built by Vincent Lavender in Massachusetts. There have been other Picaras finished in the past but I never got a sailing report for them...

And the Vole in New York is Garth Battista's of www.breakawaybooks.com, printer of my book and Max's old outboard book and many other fine sports books. Beautiful job! Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat. But he has used it extensively on his Bahamas trip towed behind his Cormorant. Sort of like having a compact car towed behind an RV.

And a Deansbox seen in Texas:

Another prototype Twister is well along:

A brave soul has started a Robbsboat. He has a builder's blog at http://tomsrobbsboat.blogspot.com. (OOPS! He found a mistake in the side bevels of bulkhead5, says 20 degrees but should be 10 degrees.) This boat has been sailed and is being tested. He has found the sail area a bit much for his area and is putting in serious reef points.

AN INDEX OF PAST ISSUES

THE WAY BACK ISSUES RETURN!

MANY THANKS TO CANADIAN READER GAETAN JETTE WHO NOT ONLY SAVED THEM FROM THE 1997 BEGINNING BUT ALSO PUT TOGETHER AN EXCELLENT INDEX PAGE TO SORT THEM OUT....

THE WAY BACK ISSUES

1nov21, Lugsail Jiffyreef, Mayfly14

15nov21, Sharpie Sprit Reef, Piccup Pram

1dec21, Junk Rig Test, Ladybug

15dec21, Taped Seams , Sportdory

1jan22, Rowboat Setup , Normsboat

15jan22, Sail Area Math , Robote

1feb22, Bulkhead Bevels , Toto

15feb22, Trailering Boats , IMB

1mar22, Small Boat Rudders , AF4Breve

15mar22, Rudder Sink Weights , Scram Pram

1apr22, Sail Rig Spars , RiverRunner

15apr22, Water Ballast, Mayfly16

1may22, AF3 Capsize, Blobster

15may22, Mast Tabernacles, Laguna

1jun22, Underwater Board Shape, QT Skiff

15jun22, Capsize Lessons, Mixer

1jul22, Scarfing Lumber, Vireo14

15jul22, Rigging Lugsails, Frolic2

1aug22, Horsepower, Oracle

15aug22, Sharpie Sprit Sails, Cormorant

1sep22, Measuring Prop Thrust, OliveOyl

15sep22, Leeboard Issues, Philsboat