Jim Michalak's Boat Designs

1024 Merrill St, Lebanon, IL 62254

A page of boat designs and essays.

(15 October 2019) We continue OliveOyling in Canada with Herb McLeod with a capsize test. The 1 November issue will keep continue the OliveOyling.

THE BOOK IS OUT!

BOATBUILDING FOR BEGINNERS (AND BEYOND)

is out now, written by me and edited by Garth Battista of Breakaway Books. You might find it at your bookstore. If not check it out at the.... ON LINE CATALOG OF MY PLANS......which can now be found at Duckworks Magazine. You order with a shopping cart set up and pay with credit cards or by Paypal. Then Duckworks sends me an email about the order and then I send the plans right from me to you.

| Left:

Herb McLeod capsizes his junk rigged OliveOyl. |

|

Herb's OliveOyl 2

HERB MCLEOD...

...has been a key help to us boaters for a long time. In my case he has prototyped different boats going back to the AF3 long ago, and then he practices capsizing in the cold Canadian waters and writes about it. He did the OliveOyl prototype last year and has spent the summer in some serious testing of different rigs. So read on and learn. I think there will be two more episodes as later he does a junk rig capsize and then some junk rig testing with gps tracking.

Herb Wrote...

Hi Jim,

"Hi Jim, A neighbour and fellow sailer Bob Huson came by on his Kayak. There was no wind and the junk sail was on the boat so asked him to take some pics with his smart phone when I capsized and recovered OlivOyl. It was a little easier to pull OliveOyl over with heavier junk rig but still took considerable effort on my part. As she went over, unlike the AF3, it was v-e-r-y s-l-o-w. To right her when the board is on the high side I have a 1/4 inch line attached with a snap fastener from the bow ring the lower offcenter board bracket. It didn't take much of a tug to pull the boat up using this line. Perhaps 10 pounds or so of pull. The boat is ballasted with the 100 pounds of lead in the bow. This keeps it level when I am sailing from the cockpit. The lead also keeps the bow of the boat down when it is on its side so that the centerline of the boat is parallel to the surface of the water. "

Cheers,

Herb

NEXT TIME...

...we'll take a look at Herb's boarding ladder.

Jonsboat

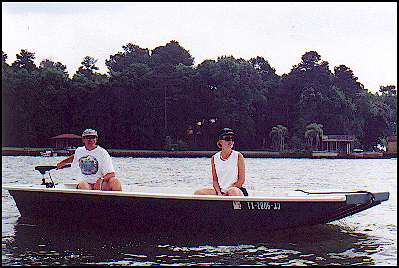

JONSBOAT, POWER SKIFF, 16' X 5', 200 POUNDS EMPTY

Jonsboat is just a jonboat. But where I live that says a lot because most of the boats around here are jonboats and for a good reason. These things will float on dew if the motor is up. This one shows 640 pounds displacement with only 3" of draft. That should float the hull and a small motor and two men. The shape of the hull encourages fast speeds in smooth water and I'd say this one will plane with 10 hp at that weight, although "planing" is often in the eye of the beholder. I'd use a 9.9 hp motor on one of these myself to allow use on the many beautiful small lakes we have here that are wisely limited to 10 hp. The prototype was built by Greg Rinaca of Coldspring, Texas and his boat is shown above when first launched with a trolling motor. But here is another one finished about the same time by Chuck Leinweber of Harper, Texas:

In the photo of Chuck's boat you can see the wide open center that I prefer in my own personal boats. To keep the wide open boat structurally stiff I boxed in the bow, used a wide wale, and braced the aft corners.

I usually study the shapes of commercial welded aluminum jonboats. It's surprising to see the little touches the builders have worked into such a simple idea. I guess they make these things by the thousands and it is worth while to study the details. Anyway, Jonsboat is a plywood copy of a livery boat I saw turned upside down for the winter. What struck me about that hull was that its bottom was constant width from stem to stern even though the sides had flare and curvature. When I got home I figured out they did it and copied it. I don't know if it gives a superior shape in any way but the bottom of this boat is planked with two constant width sheets of plywood.

Greg Rinaca put a new 18 hp Nissan two cycle engine on his boat, Here is a photo of it:

The installation presented a few interesting thoughts. First I've been telling everyone to stick with 10 hp although it's well known that I'm a big chicken about these things. Greg reported no problems and a top speed of 26 mph. I think the Coast Guard would limit a hull like this to about 25 hp, the main factors being the length, width, flat bottom, and steering location. Second, if you look closely at the transom of Greg's boat you will see that he has built up the transom in the motor mount area about 2". When I designed Jonsboat I really didn't know much about motors except that there were short and long shaft motors. I thought the short ones needed 15" of transom depth and didn't really know about the long shafts. Jonsboat has a natural depth of about 17" so I left the transom on the drawing at 17" and did some hand waving in the drawing notes about scooping out or building up the transom to match the requirements of your motor.

I think the upshot of it all is that short shaft motors need 15" from the top of the mount to the bottom of the hull and long shaft motors need 20". There was a lot of discussion about where the "cavitation" plate, which is the small flat plate right above the propellor, should fall with respect to the hull. I asked some expert mechanics at a local boat dealer and they all swore on a stack of tech manuals that a high powered boat will not steer safely if the cavitation plate is below the bottom of the hull, the correct location being about 1/2" to 1" above the bottom. But Greg had the Nissan manual and it said the correct position is about 1" BELOW the bottom. Kilburn Adams has a new Yamaha and its manual says the same thing. So I guess small motors are different from big ones in that respect.

But it seems to be not all that critical, at least for the small motors. Greg ran his Jonsboat with the 18 hp Nissan with the original 17" transom for a while and measured the top speed as 26 mph. Then he raised the transom over 2" and got the same top speed!

There is nothing to building Jonsboat. There five sheets of plywood and I'm suggesting 1/2" for the bottom and 1/4" for everything else. It's all stuck together with glue and nails using no lofting or jigs. I always suggest glassing the chines for abrasion resistance but I've never glassed more than that on my own boats and haven't regretted it. The cost, mess, and added labor of glassing the hull that is out of the water is enormous. My pocketbook and patience won't stand it. Glassing the chines and bottom is a bit different because it won't show and fussy finishing is not required.

Plans for Jonsboat are $25.

Prototype News

Some of you may know that in addition to the one buck catalog which now contains 20 "done" boats, I offer another catalog of 20 unbuilt prototypes. The buck catalog has on its last page a list and brief description of the boats currently in the Catalog of Prototypes. That catalog also contains some articles that I wrote for Messing About In Boats and Boatbuilder magazines. The Catalog of Prototypes costs $3. The both together amount to 50 pages for $4, an offer you may have seen in Woodenboat ads. Payment must be in US funds. The banks here won't accept anything else. (I've got a little stash of foreign currency that I can admire but not spend.) I'm way too small for credit cards.

We have a Picara finished by Ken Giles, past Mayfly16 master, and into its trials. The hull was built by Vincent Lavender in Massachusetts. There have been other Picaras finished in the past but I never got a sailing report for them...

And the Vole in New York is Garth Battista's of www.breakawaybooks.com, printer of my book and Max's old outboard book and many other fine sports books. Beautiful job! Garth is using a small lug rig for sail, not the sharpie sprit sail shown on the plans, so I will continue to carry the design as a prototype boat. But he has used it extensively on his Bahamas trip towed behind his Cormorant. Sort of like having a compact car towed behind an RV.

And a Deansbox seen in Texas:

Another prototype Twister is well along:

A brave soul has started a Robbsboat. He has a builder's blog at http://tomsrobbsboat.blogspot.com. (OOPS! He found a mistake in the side bevels of bulkhead5, says 20 degrees but should be 10 degrees.) This boat has been sailed and is being tested. He has found the sail area a bit much for his area and is putting in serious reef points.

AN INDEX OF PAST ISSUES

THE WAY BACK ISSUES RETURN!

MANY THANKS TO CANADIAN READER GAETAN JETTE WHO NOT ONLY SAVED THEM FROM THE 1997 BEGINNING BUT ALSO PUT TOGETHER AN EXCELLENT INDEX PAGE TO SORT THEM OUT....

THE WAY BACK ISSUES

1nov18, Sink Weights, Shanteuse

15nov18, Piccup Spinoffs, Piccup Pram

1dec18, Electric Boats 1, Ladybug

15dec18, Electric Boats 2, Sportdory

1jan19, Sail Area Math, Normsboat

15jan19, AF3Capsize, Robote

1feb19, Bulkhead Bevels, Toto

15feb19, Leeboard Issues, IMB

1mar19, Hollow Spars, AF4 Breve

15mar19, Underwater Board Shape, Harmonica

1apr19, Polytarp Sails 1, River Runner

15apr19, Polytarp Sails 2, Mayfly16

1may19, Sail Shaping, Blobster

15may19, Sail Shaping 2, Laguna

1jun19, Capsize Lessons, QT Skiff

15jun19, Rend Lake 2019, Mixer

1jul19, Scarfing Lumber, Vireo14

15jul19, Rigging Lugsails, Vamp

1aug19, Rigging Sharpie Spritsails, Oracle

15aug19, Rowing1, Cormorant

Table of Contents